|

设计简介 |

设计描述:

文档包括:

word说明书一份,共42页,约13000字

CAD版本图纸,共3张

四座微型客货两用车—变速器、传动轴和操纵机构设计

摘 要

变速器、传动轴和操纵机构是汽车动力重要组成部分,本设计是建立在参考国内外大量微型客货两用车动力设计的基础之上,在设计中注重实际运用并密切联系小组成员的整车总体布置、离合器、驱动桥、车架、制动系的设计。实现变速器与发动机及其他机构的最佳匹配,力求整车结构及性能更为合理。

变速器主要用来改变发动机传到驱动轮上的转矩和转速,目的是在起步、爬坡、转弯、加速等各种行驶工况下,使汽车获得不同的牵引力和速度,同时使发动机在最有利的工况下范围工作,本设计设有四个前进档、空档和倒档。变速器的结构直接影响汽车的动力性,经济性,操纵可靠性。

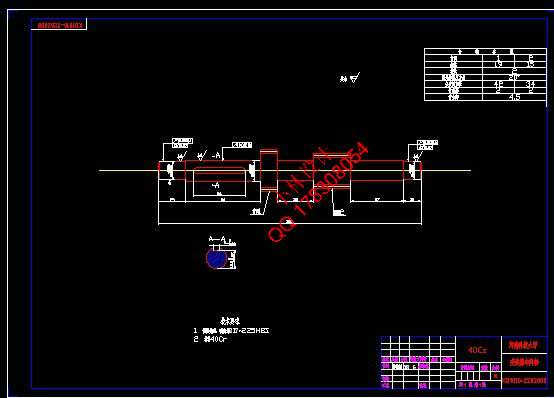

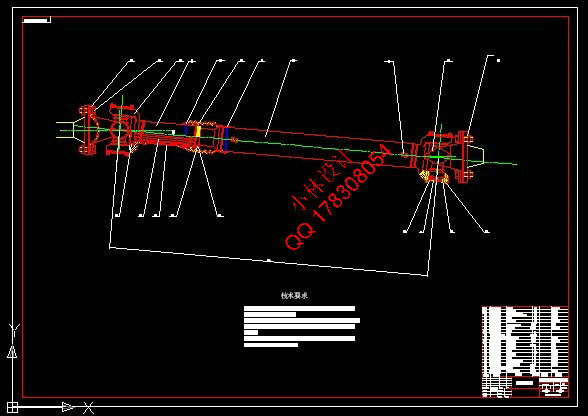

设计主要分为三个部分。在变速器设计上先进行其结构分析,在参数方面考虑档数,传动比,及其如何分配传动比。在变速器齿轮设计中,主要考虑材料、强度和齿数的确定;传动轴方面,通过对传动轴的传动类型与结构分析,对传动轴的临界转速和计算载荷的确定,分析出传动轴的花键轴和轴管的尺寸,并校核了其扭转强度和临界转速,确定出合适的安全系数;操作机构方面,考虑到微型客货两用车的使用条件和要求,为了协调驾驶室、总体布置等问题,本次设计采用双拉杆式远距离换档操纵机构和单杆式高低档换档操纵机构。

关键词:变速器,传动轴,操纵机构,微型客货两用车

FOUR SEATS MINI-STATION WAGGON TRANSMISSION PROPELLER SHAFT AND OPERATED MECHANISM

ABSTRACT

The structure of the transmission ,powerller shaft and operated mechanism are the most important parts of the vehicle. The design is referrenced many of the power about minitype station waggons in domestic and oversea. During design times, I attented the fact using in lives and interosculate my co-worker’s design, it included collectivity disposal, clutch , main frame,drive axle ,brake system. Gearbox can be well worked with engine and other machines. It wanted to be that the performance of the whole vehicle reasonable.

The transmission is main used for changing engine’s power which transmited to the torque and revolution on the drive wheel.When the vehicle under the case about starting, mountain climbing, swerving,adding speed that the transmission can give different power or speed to the vehicle. At the same time,the engine can work in good conditions.The design involved four D-drive,one R-reverse and one N-neutral. The structure of the transmission can influence the vehicle’s power, economic, controling.

The design involved three parts in all,first, I analyse its structure,In parameter the main thinking is about the number of shaft,gear ratios and how to assign them. In gear design the main problem is materials ,intension and NO. of wheel; In transmission shaft,through analysing the varieties and structures that be sure the critical of rotate speed and the data of load.The data about shaft spline and tubal,and checking its torsion and critical rotate speed to find the reasonable safety data; on the handle machine , I think about the using condition and request of the minitype station waggonsin, by way of assorting with cab,collectivity collocation and ect. The design used double draw-haulm, it can be controled in long distance and also it used high and low single-haulm to change the shift.

KEY WORDS:transmission,powerller shaft,operated mechanism, minitype station waggon

目 录

第一章 前言.............................................1

第二章 传动轴的设计.............................2

§2.1 传动轴的设计标准..........................2

§2.2 万向传动的计算载荷........................3

§2.3 十字轴设计计算............................4

§2.4 十字轴滚针轴承计算........................5

§2.5 万向节叉的设计计算........................6

§2.6 传动轴临界转速计算........................8

§2.7 轴管强度计算..............................10

§2.8 传动轴花键轴的计算........................10

第三章 变速器的结构分析..........................12

§3.1 概述.....................................12

§3.2 变速器的总体结构........................12

§3.3 变速器操纵机构..........................14

第四章 变速器主要参数的确定......................16

§4.1 挡数选择...............................16

§4.2 主减速器传动比...........................16

§4.3 分配各挡传动比........................16

§4.4 初定中心距.............................17

§4.5 齿轮模数的选取..........................17

§4.6 压力角.................................17

§4.7 螺旋角的选择...........................17

§4.8 齿宽的选择...............................18

第五章 齿轮参数的选择计算........................19

§5.1变速器各挡齿数的确定......................19

§5.2 齿轮的设计计算..........................20

第六章 变速器齿轮的强度计算及材料的选择..........24

§6.1 齿轮的材料选择........................24

§6.2 齿轮的破坏形式........................24

§6.3 强度的校核........................25

第七章 变速器轴的设计计算........................26

§7.1 估算轴的直径........................26

§7.2 变速器轴的强度校核计算....................26

第八章 轴承的设计计算............................31

第九章 结论..............................33

参考文献...................................34

致谢.....................................35

|