|

|

|

|

设计名称 |

轻型卡车离合器设计[汽车] |

|

|

设计编号 |

Z079 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

23000字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

2013.09.26 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

设计描述:

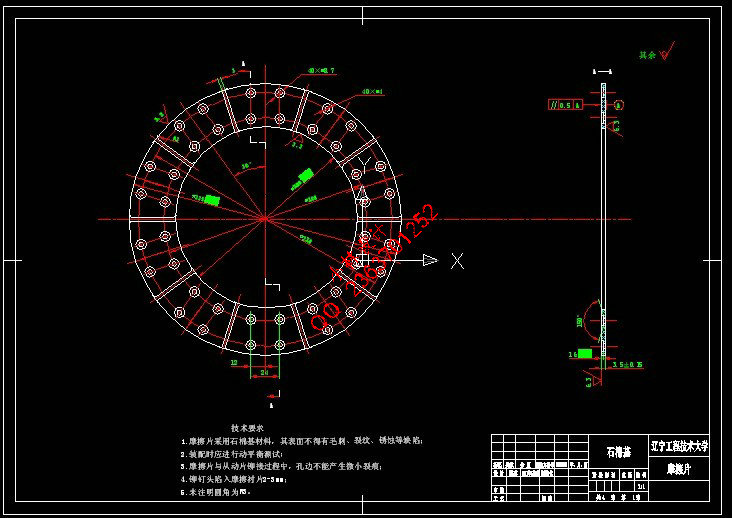

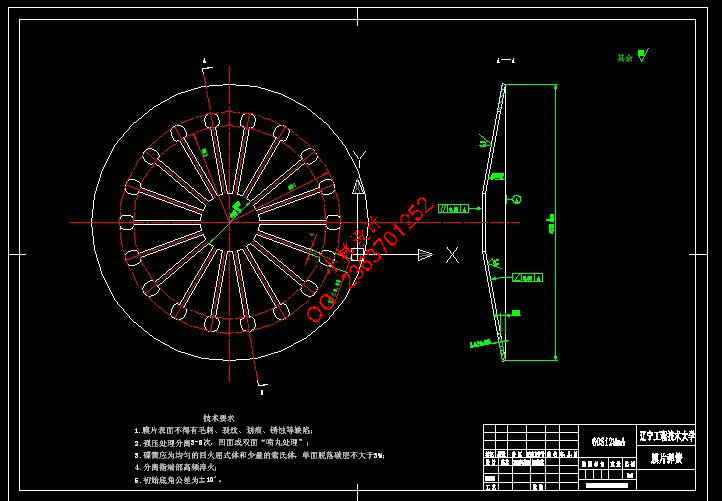

文档包括: CAD版本图纸,共4张 摘要 离合器是汽车传动系中直接与发动机相连接的总成,其主要功用是切断和实现对传动系的动力传递,保证汽 车起步时将发动机与传动系平顺地接合,确保汽车平稳起步;在换挡时将发动机与传动系分离,减少变速器 中换挡齿轮之间的冲击;在工作中受到大的动载荷时,能限制传动系所承受的最大转矩,防止传动系各零件

因过载而损坏;有效地降低传动系中的振动和噪声。 器是近年来在汽车上广泛采用的一种离合器,它的转矩容量大而且较稳定,操作轻便,平衡性好,也能大量 生产,对于它的研究已经变得越来越重要。此设计说明书详细的说明了重型载货汽车膜片弹簧离合器的结构

形式,参数选择以及计算过程。 了结构方案及有关参数,进行了总成设计,并对其一些零件进行了校核:包括摩擦片外径的确定,离合器后 备系数的确定,单位压力的确定,从动盘设计,压盘设计,膜片弹簧设计等,为以后从事汽车技术工作打下

良好的基础。不仅如此,本次设计借鉴了相关的资料,采用了相关的标准,充分吸收了前人宝贵的经验。

Clutch is the assembly which is directly connected with engine in the automobile power train. And its main function is to cut off and implement the transmission of power in the power train. It ensures the engine and the power train perfectly smooth join together when the automobile is starting up and insures the automobile started up smooth. The clutch disconnects the engine and the power train when the automobile stage change over. It reduces the impact between the shift gears of the transmission. When the transmission worked on the great dynamic load, the clutch can limit the breakdown torque of the power train in order to prevent the accessory of the power train that is damaged due to overload. It also can effectively reduce the vibration and

noise of the power train. it is identified with the pull-type diaphragm spring clutch as the design goal. In recent years, diaphragm spring clutch is a kind of clutch that was widely adopted in saloon cars and light vehicles. It has great capacity of torque and more stable. Meanwhile it manipulate conveniently and has good balance. And It also has high output. So the research of the clutch is become more and more important. This design manual elaborated on the construction form, the

parameters choose and process of calculate of the light trucks. well as "three" (that is seriation, universalization and standardization) requirements, and so on, this design choose the structure scheme and relevant parameters. Meanwhile this design complete assembly design and checking for some of its parts. They include the determination of friction plate diameter, the determination of backup coefficient, the determination of the unit pressure, the design of driven plat, the design of pressure plate and diaphragm, etc. This design can lay a good foundation for engaging in vehicle technology work in the future. In addition, this design profit from the related material, and use the related standard, and fully

absorb predecessors' valuable experience.

1绪论 1 |

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1