|

设计描述:

文档包括:

word说明书一份,共38页,约20000字

CAD版本图纸,共6张

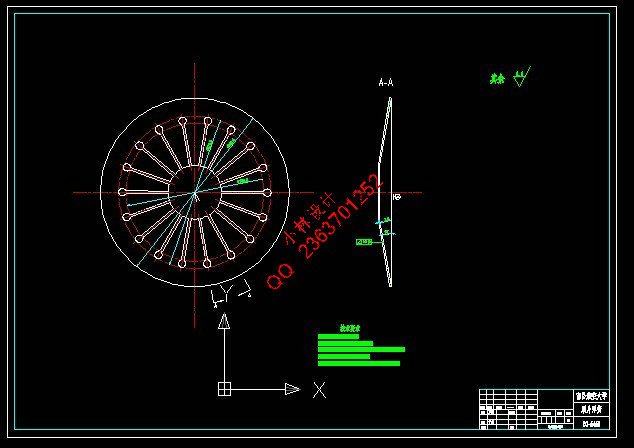

长城赛弗F1汽车的离合器设计

摘要: 离合器是汽车传动系中的重要部件,主要功用是是切断和实现发动机对传动系的动力传递,保证汽车平稳起步,保证传动系统换挡时工作平顺以及限制传动系统所承受的最大转矩,防止传动系统过载。膜片弹簧离合器是近年来在轿车和轻型汽车上广泛采用的一种离合器,它的转矩容量大而且较稳定,操作轻便,平衡性好,也能大量生产,对于它的研究已经变得越来越重要。此设计说明书详细的说明了轻型汽车膜片弹簧离合器的结构形式,参数选择以及计算过程。

本文根据选定的发动机容量与汽车的相关参数,进行设计,确定了以推式膜片弹簧离合器作为设计目标。根据推式膜片弹簧离合器工作原理和使用要求,采用系统化设计方法,把离合器分为主动部分、从动部分、操纵机构。通过对各个部分设计方案的原理阐释和优缺点的比较,确定了相关部分的基本结构及其零部件的制造材料。根据车辆使用条件和车辆参数,按照离合器系统的设计步骤和要求,主要进行了以下工作:选择相关设计参数,离合器容量参数,离合器后备系数β的确定,单位压力P的确定,摩擦片外径D的确定。并进行了总成设计主要为:减震从动盘设计,压盘设计,离合器盖设计和膜片弹簧的设计。

关键字:膜片弹簧离合器 膜片弹簧 离合器 摩擦片 减震盘

指导老师签名:

Clutch design of Changcheng saifo F1car

Abstract: Clutch is an important component in the automotive transmission. Main function is to cut off the engine and the realization of the power from the transmission to ensure a smooth start and prevent transmission from overload.Diaphragm spring clutch in car in recent years,widely used as a vehicle clutch.Its large capacity ,stable torque and easy operation, good balance, but also mass production for which research has become increasingly important. This design specification describes in detail the diaphragm spring clutch light vehicle structure, parameter selection and calculation

Based on the selected engine capacity and vehicle-related parameters, design, determined to push-type diaphragm spring clutch as a design goal。Push-type diaphragm spring clutch according to the principle and application requirements, the use of systematic design method is divided into active part of the clutch, the driven part of the control mechanism. Through the design of various parts of the principle of interpretation and the advantages and disadvantages compared to determine the relevant part of the basic structure and components of the manufacturing materials. According to traffic conditions and vehicle parameters, in accordance with the clutch system design steps and requirements, mainly for the following work: select the relevant design parameters, clutch size parameters, the determination of clutch back coefficient β, the determination of unit pressure P, the determination of friction plate diameter D. And were designed primarily for assembly: shock driven plate design, the design pressure plate, clutch cover design and the design of the diaphragm spring.

Key words: clutch diaphragm springs friction plate driven plate pressure plate.

Signature of Supervisor:

目 录

1 绪论........................................................ (1)

1.1 课题研究的目的和意思....................................... (1)

1.2 国内外的研究现状和发展趋势................................. (1)

1.3 膜片弹簧离合器的结构及其优点............................... (3)

1.4 设计内容及要求............................................. (5)

2 离合器结构方案分析....................................... (6)

2.1 从动盘的选择............................................... (6)

2.2 压紧弹簧和布置形式的选择....................................(6)

2.3压盘的驱动形式.............................................. (7)

2.4离合器的通风散热............................................ (7)

2.5设计方案的确定.............................................. (8)

3 离合器主要参数的选择.................................... (8)

3.1 离合器基本性能关系式....................................... (8)

3.2 后备系数的选择............................................. (9)

3.3 摩擦因数f、摩擦面数Z和离合器间隙△t...................... (10)

3.4 单位压力 .................................................(10)

3.5摩擦片外径的确定及校核..................................... (11)

4 主动部分设计............................................. (13)

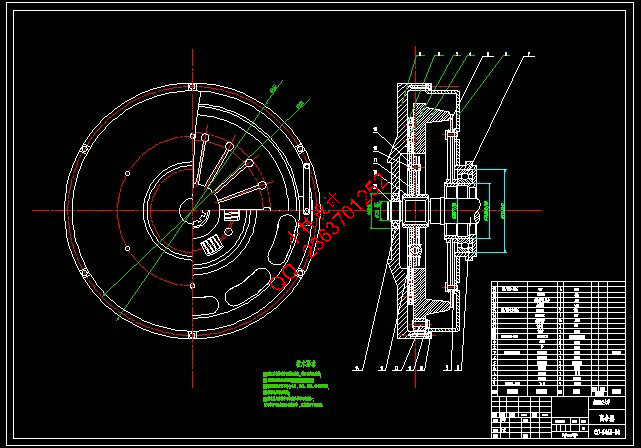

4.1 压盘设计.................................................. (13)

4.2 离合器盖设计.............................................. (15)

4.3 传动片设计................................................ (15)

5 从动盘总成设计........................................... (18)

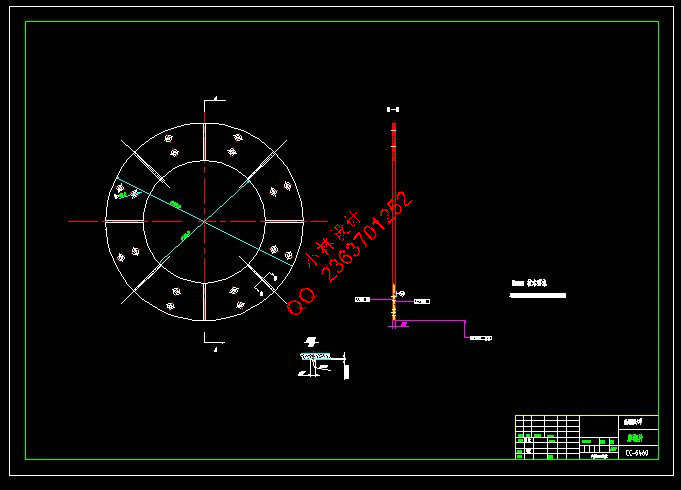

5.1 从动盘结构介绍............................................ (18)

5.2 摩擦片设计................................................ (18)

5.3 从动盘毂设计.............................................. (19)

5.4 从动片设计................................................ (21)

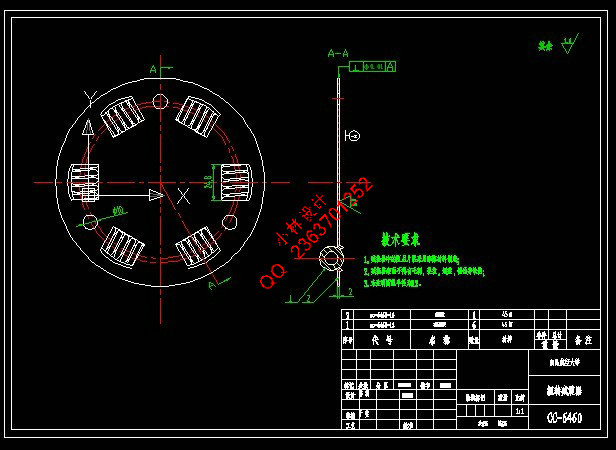

5.5扭转减振器设计............................................. (21)

6 膜片弹簧设计............................................. (26)

6.1 膜片弹簧的概念............................................ (26)

6.2 膜片弹簧的弹性特性........................................ (26)

6.3 膜片弹簧的强度计算........................................ (29)

6.4 膜片弹簧基本参数的选择.................................... (30)

6.5膜片弹簧材料及制造工艺.....................................(32)

结论........................................................ (33)

参考文献..................................................... (34)

致谢.......................................................... (35)

|