|

设计简介 |

设计描述:

文档包括:

word说明书一份,共43页,约18000字

CAD版本图纸,共9张

SolidWorks三维图,一套

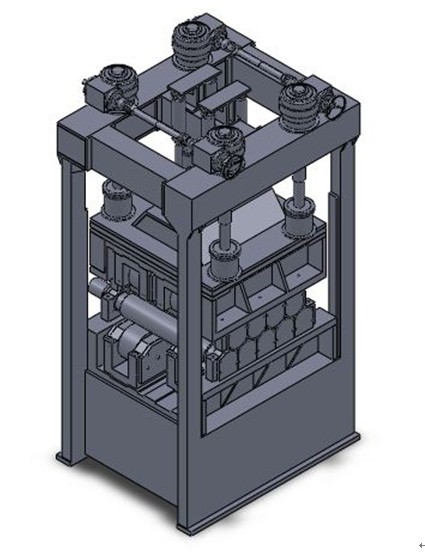

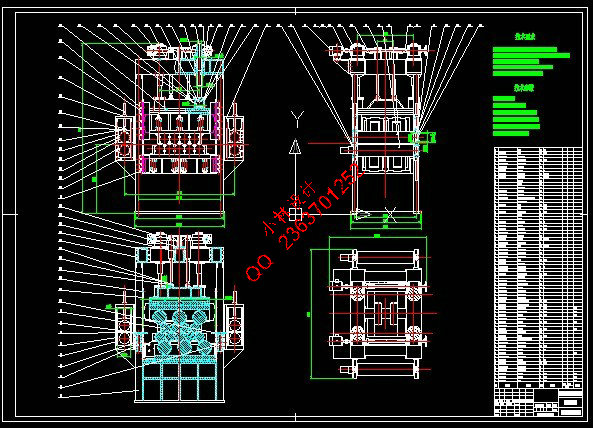

20-40mm板材矫直机设计

摘 要

在轧制生产过程中,由于塑性变形、冷却不均或运输等一系列原因使轧件产生不同程度的挠曲、瓢曲、波浪、镰刀弯和歪扭,或内部残余应力,从轧机出来的轧件往往具有不平直性和形状尺寸精度误差较大的情形。因此矫直技术是提高板带钢产品表面质量和平坦度的重要环节。

本文介绍了平行板矫直机的结构特点和功能。并且对矫直机的发展趋势和实际生产中存在的问题做了阐述。本次设计的矫直机是用来矫正钢板在轧制过程中产生的各种弯曲和瓢曲,通过矫正可消除钢板弯曲应力,并提高钢板的平直度,达到用户的要求。设计中对矫直原理做了详细具体的阐述,对其主要零部件做了校核,对矫直机的力能参数做了计算,同时包括机架、上矫直辊系、下矫直辊系、压下与平衡系统等主要部件的设计。为了避免矫正时的冲击,压下装置中装有机械式平衡机构,平衡弹簧装在托盘上通过拉杆来平衡上活动横梁的全部重力,并能消除螺母与螺杆直角的窜动间隙。托盘将全部重力通过推力轴承压到平衡螺母上,而平衡螺母又通过内齿圈与蜗轮螺母联结成同步转动又互不相压的关系。

关键词:板材矫直机,平行辊式,压下与平衡装置

20-40mm straightening marching design

Abstract

In rolling production process, a number of reasons such as plastic deformation, uneven cooling or transportation make a rolled produce different degrees of bending, buckling, wave, bend, and the crooking, or internal residual stress. Rolled from the rolling mill are often with bad shape and size and larger error precision. So the straightening marching has been an important part to enhance the surface quality and flatness of the production.

This article describes the structure, features and functions of parallel plate straightening marching. The development trend of the straightening machine and the actual production problems are also described in detail. The design of the straightening machine is used to correct plate in the rolling process for a variety of bending and buckling. By correcting plate can eliminate bending stress, and improve the flatness of steel plate to the user's requirements. The design includes a detailed concrete exposition of the principle of straightening, check of its main components and the calculation of parameters of the straightening machine. It also includes the design of the rack, the upper straightening rolls and lower straightening rolls, the pressure and balance system, and other major components. In order to avoid the impact, the device equipped with a mechanical balance body and balance spring mounted on the tray through the rod to balance all the gravity of the upper moving beam and also to remove the nut and screw at right angles to traverse the gap. The tray puts all the gravity pressure on the balance through and the thrust bearing nut while the balance nut ring gear linked the balance nut and the worm nut into a synchronous rotation and no pressure between each other.

Key words: Plate straightening machine, Roll, Pressure and the balance device

目 录

第1章 绪论 1

1.1 设计背景 1

1.2 国内外研究现状、发展动态 1

1.3矫直机的类型 3

1.3.1应用弹塑性弯曲变形进行矫直 3

1.3.2应用弹塑性拉伸变形进行矫直 5

1.3.3利用弹塑性扭转变形进行矫直 6

1.3.4应用轧压原理进行矫直 6

1.3.5应用组合变形进行矫直 6

1.4 平行辊矫直机简介 7

1.4.1平行辊矫直机的矫正过程 7

1.4.2平行辊矫直机的优缺点 8

1.5 设备概况 8

第2章 平行辊矫直机的参数计算 11

2.1 技术参数 11

2.2 结构参数计算 11

2.3 力能参数计算 12

2.31 矫直力与矫直力矩的计算 12

2.32 矫直功率的计算 13

第3章 主要部件设计 17

3.1主传动系统设计 17

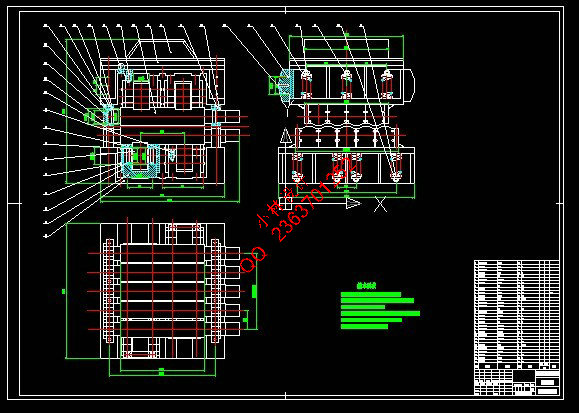

3.2下矫直辊系 17

3.3上矫直辊系 18

3.4上下支承辊及调整装置 18

3.5压下平衡系统 19

3.6机架 21

3.7导卫装置 21

3.8润滑 22

3.9电控装置 22

3.10结论 23

第4章 主要部件的校核 31

4.1矫直辊的校核计算 31

4.1.1 矫直机矫直扭矩的计算 31

4.1.2第三辊弯曲力矩的计算 32

4.1.3支反力的确定 35

4.2矫直辊强度的计算 36

4.3 轴承寿命的校核 37

参考文献 - 39 -

结束语 - 41 -

附录 42

|