|

设计描述:

文档包括:

word说明书一份,共39页,约12000字

CAD版本图纸,共4张

CATIA三维,一套

摘要

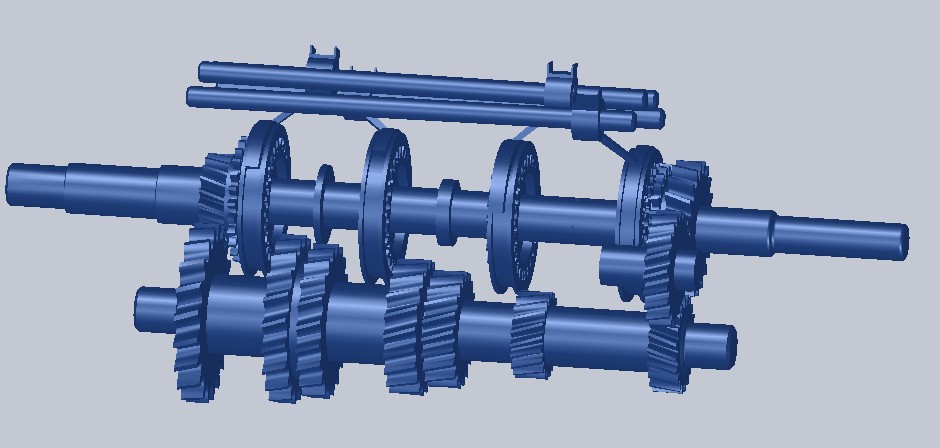

变速器是汽车传动系统中重要的部件,主要用来改变发动机传到驱动轮上的转矩和转速,它设计的好坏直接影响到汽车的实际使用性能。本文参考现有变速器参数资料的基础上进行一定的改进,说明了汽车变速器的设计计算过程,主要内容是参数的选择和所选零件参数的校核。

本文叙述了机械式变速器的功用、要求,在已提供的设计参数基础上,通过计算分析确定结构方案和主要参数。说明了变速器主要参数的确定方法、齿轮的几何计算和校核过程、轴的尺寸确定和校核过程和同步器的选用方法。

汽车变速器是通过改变传动比,改变发动机曲轴的转拒,适应在起步、加速、行驶以及克服各种道路阻碍等不同行驶条件下对驱动车轮牵引力及车速不同要求的需要。

关键词: 变速器;传动机构;齿轮;离合器;传动比

Abstract

Transmission System is the most important automotive components, mainly used to change the engine driving wheel on the spread of torque and speed, it’s designed to have a direct impact on the actual use of motor vehicles. In this paper, reference information on the existing transmission parameters on the basis of certain improvements on the vehicle transmission design and calculation process, the main contents of the parameters of choice and selected parts of the parameters check.

This paper describes the function of mechanical transmission, requested that the provision has been on the basis of the parameters, determined by calculating the structure of the programme and the main parameters. Description of the main parameters of transmission methods, the geometric computing gear and checking process, the shaft size and the identification and verification process for the selection method of synchronization. Calculation includes gear strength, the axis of mild stiffness

Automobile transmission is by changing the transmission ratio, the engine crankshaft in turn refused to change and adapt at the start, acceleration, road traffic and to overcome the obstacle of different driving conditions and speed of the drive wheel traction with different demands and needs.

Key words: transmission; transmission; gear; clutch; transmission ratio

目 录

摘要..............................................................................................................I

Abstract...............................................................................................................II

第1章 绪论.................................................................................................1

第2章 机械式变速器的概述及其方案的确定..........................................3

2.1 变速器的功用和要求.................................................................3

2.2 变速器结构方案的确定.............................................................3

2.2.1变速器传动机构的结构分析与型式选择.........................3

2.2.2.倒档传动方案...................................................................8

2.3变速器主要零件结构的方案分析.........................................9

2.3.1齿轮型式............................................................................9

2.3.2换档结构型式....................................................................9

第3章 变速器主要参数的选择与主要零件的设计................................12

3.1 变速器主要参数的选...............................................................12

3.1.1 档数和传动比.................................................................12

3.1.2 中心距........................................................................ ....14

3.1.3 轴向尺寸.........................................................................14

3.1.4 齿轮参数........................................................................ 15

3.2各档传动比及其齿轮齿数的确定.............................................16

3.2.1确定一档齿轮的齿数.......................................................16

3.2.2确定常啮合齿轮副的齿数...............................................16

3.2.3确定其他档位的齿数.......................................................17

3.2.4确定倒档齿轮的齿数...................................................... 17

3.3 齿轮变位系数的选择...............................................................17

第4章 变速器齿轮的强度计算与材料的选择....................................,...19

4.1齿轮的损坏原因及形式............................................................19

4.2 齿轮的强度计算与校核...........................................................19

4.2.1齿轮弯曲强度计算..........................................................19

4.2.2 齿轮接触应力.................................................................20

第5章 变速器轴的强度计算与校核.......................................................24

5.1变速器轴的结构和尺寸............................................................24

5.1.1轴的结构..........................................................................24

5.1.2确定轴的尺寸..................................................................24

5.2 轴的校核..................................................................................25

5.2.1第一轴的强度与刚度校核.................................................25

5.2.2第二轴的校核计算............................................................26

第6章 变速器同步器的设计...................................................................29

6.1 同步器的结构......................................................................... ...29

6.2 同步环主要参数的确定.............................................................39

6.2.1同步环锥面上的螺纹槽.....................................................39

6.2.2锥面半锥角 ....................................................................30

6.2.3摩擦锥面平均半径R..........................................................30

6.2.4锥面工作长度b.................................................................31

6.2.5同步环径向厚度................................................................31

6.2.6锁止角 ............................................................................31

6.2.7同步时间t.........................................................................31

第7章 变速器的操纵机构.......................................................................33

结论..........................................................................................................34

致 谢.................................................................................................. .....35

参考献........................................................................................................36

本设计是根据流行1.8L大众途观车型而开展的,设计中所采用的相关参数均来源于此种车型:

主减速比:4.782

最高时速:190km/h

轮胎型号:215/65R16

发动机型号:1.8TSIEA888

最大扭矩:250Nm

最大功率:118kw

扭矩转速:4200r/min

|