|

|

|

|

设计名称 |

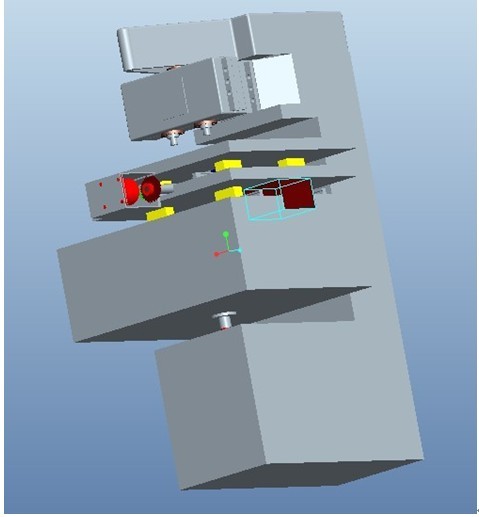

双搅拌轴搅拌摩擦焊机设计[Proe三维] |

|

|

设计编号 |

z089 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

14000字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

2013.09.26 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

设计描述:

文档包括:

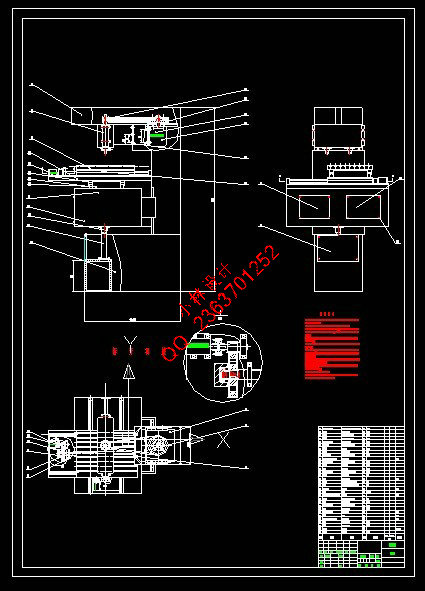

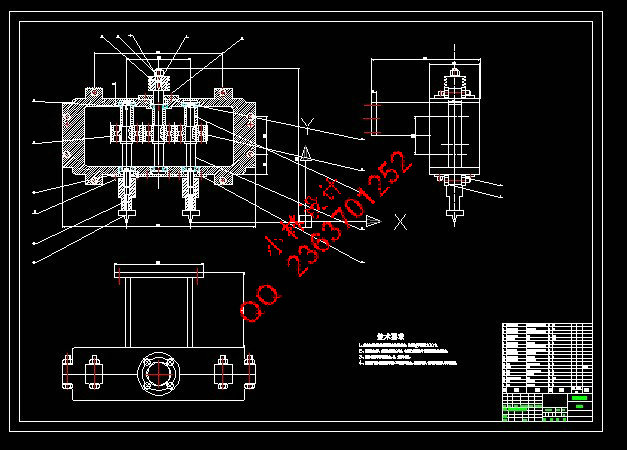

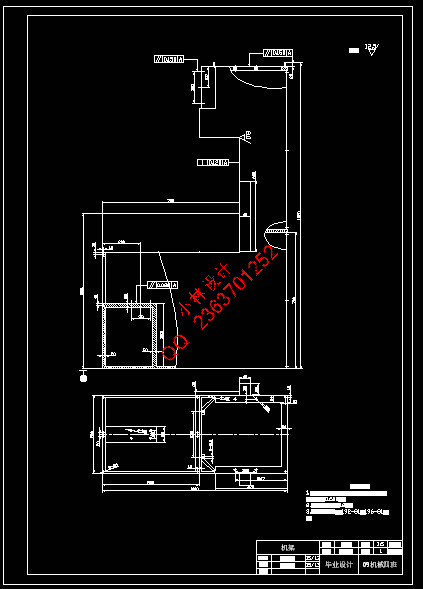

CAD版本图纸,共23张

搅拌摩擦焊技术是90年代发展起来的、自发明到工业应用时间跨度最短和发展最快的一项新型固相连接新技术,公认为是最有前途和最适合航空材料以及结构件制造的工艺方法之一。搅拌摩擦焊(FSW)是一个相对较新的固态焊接过程。这种连接技术具有节能,高效,环保,用途广泛的特点。特别是,它可以用于高强度航天铝合金和其他金属的合金,这些合金是很难通过常规焊接熔焊。 FSW被认为是金属连接在十年的发展中最有标志性的成果。[6]

Friction stir welding (FSW) was firstly used in the 1990s, which is swiftest in development and is shortest in time from being invented to being applied, it is also treated as one of the technology that have a bright future and the most suitable for aviation and component manufacture.Friction stir welding (FSW) is a relatively new solid-state joining process. This joining technique is energy efficient, environment friendly, and versatile. In particular, it can be used to join high-strength aerospace aluminum alloys and other metallic alloys that are hard to weld by conventional fusion welding. FSW is considered to be the most significant development in metal joining in a decade.

|

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1