|

|

|

|

设计名称 |

水泵平衡装置设计 |

|

|

设计编号 |

Z097 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

16000字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

2013.9.26 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

设计描述:

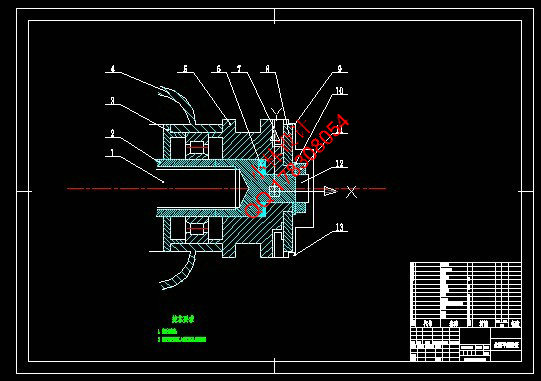

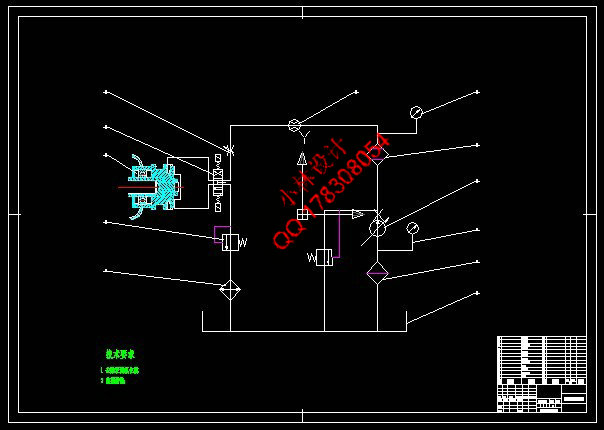

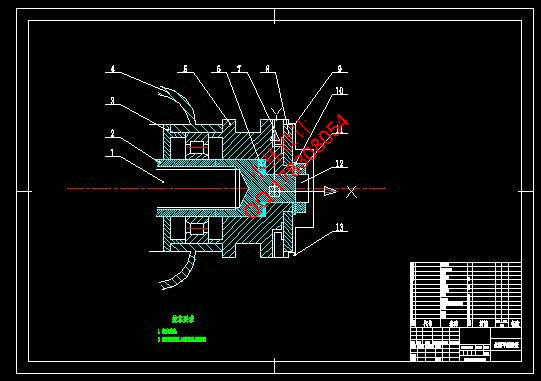

文档包括: CAD版本图纸,共3张 目录

前言………………………………………………………………………………1

研究的目的是采取液体静压支承来平衡轴向力的方法。改善矿山排水装置平衡盘受力状况,解决离心 水泵轴向力引起磨损严重的问题。延长水泵使用寿命,提高效率,降低矿井排水装置的维修费用。液 体静压支承是借助于输入支承工作面间的液体静压力来支承载荷的滑动支承。它处于纯液体润滑条件 下工作。液体静压支承具有速度范围宽、支承能力大、运动精度高、抗振性能好和使用寿命长等优点 。但液体静压支承需要一套液压供油系统,润滑油的过滤精度要求较高。本文以150D30 9型泵轴向力 的液体静压支承平衡为例。并且适合在各种型号的矿用的水泵的改装,起到代替平衡盘的作用。因为 盘之间的较小间隙处容易堵塞,另一方面,固体颗粒会加快平衡盘的磨损,造成平衡盘与平衡环之间

的间隙增大,达不到原有的平衡作用。所以矿用水泵可广泛采用液体静压支承来平衡轴向力。 Abstract We study the issue in order to introduce the method which static pressure supporting is able to solve the problem caused by the axial force of multistage centrifugal pump .It improve the force on the balance disk. Not only the method is good to increase working life and the efficiency for water pump but also it reduces the cost of maintenance. The static pressure supporting is able to work because of the hydrostatic pressure between the working surface .It works with the condition of the pure liquid Lubrication .There are some advantage such as having the wide range of speed, carrying power well , the movement precision highly and working life is long. But the static pressure supporting has to need a set of supplying oil systems. The lubricating oil need to be higher precision. Talking the static equilibrium of axial force of pump 150D30 9 as the example. Kinds of pump may are improved with the method. On the one hand there are a lot of slit blocked easily in the balance disk, on the other hand the solid particle can break balance disk, which increases slit between balance disk and balance disk ring.

Therefore we may use widely the static pressure supporting method in mine pump fields. disk |

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1