|

|

|

|

设计名称 |

无碳重力势能小车设计 |

|

|

设计编号 |

Z116 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

7500字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

2013.09.26 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

设计描述:

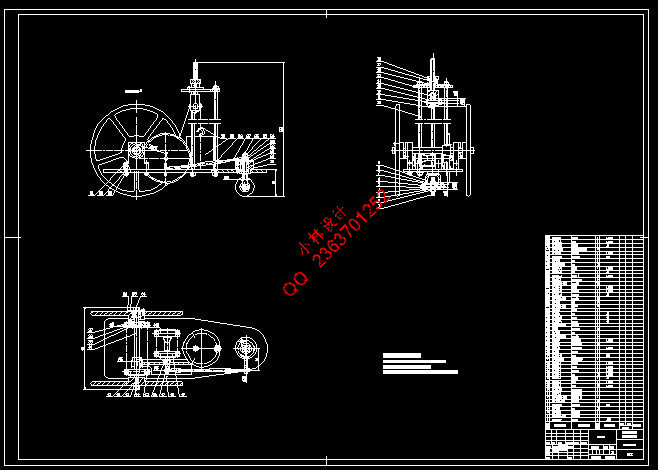

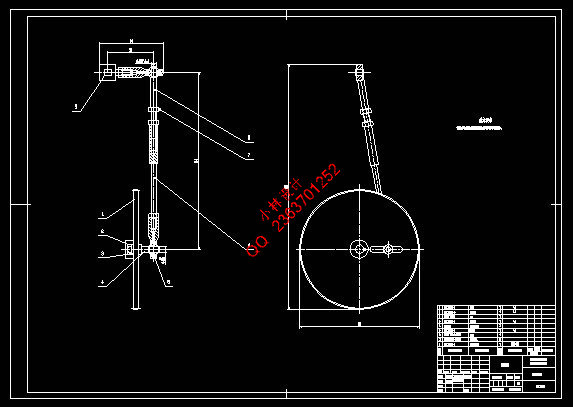

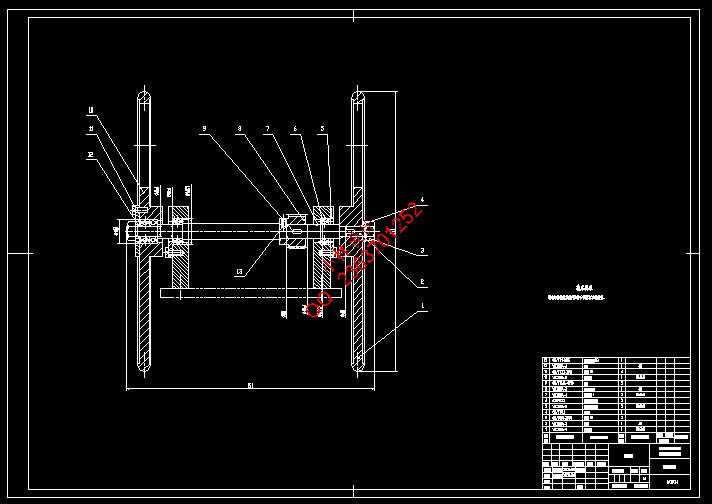

文档包括: CAD版本图纸,共5张

摘 要 为了改进小车的不足之处,对小车的结构部分进行重新设计。通过每一阶段的深入分析把设计尽可能向最优

设计靠拢。 ,进行模块化设计。首先针对每一个模块进行多方案设计,通过综合对比选择出最优的方案组合。确定的方 案为:车架采用三角底板式、原动机构采用了锥形轴、传动机构采用齿轮、转向机构采用曲柄摇杆、行走机 构采用单轮驱动实现差速、微调机构采用微调螺母。然后对方案进行理论分析,综合考虑零件材料性能、加 工工艺等,进而得出了小车的具体参数,和运动规律。 关键字:工程训练;参赛作品;重力势能小车;

Abstract potential energy car" analysis. Find cart in the design deficiencies. In order to improve the deficiency of the trolley car, a portion of the structure redesign. Through each phase of the

in-depth analysis of the design as possible to move closer to optimal design. mechanism, a transmission mechanism, a steering mechanism, a walking mechanism, a fine adjustment mechanism of six modules, modular design. First, for each module performs multiple design, through comprehensive comparison and choose the optimal scheme of combination. Determining the scheme are: frame with triangular bottom plate type, motive mechanism adopts a conical shaft, the drive mechanism adopts gear, steering mechanism with crank rocker, walking mechanism driven by a single wheel to achieve differential, fine tuning mechanism by fine adjustment nut. Then the scheme theory analysis, considering the parts and materials properties, processing technology, and then the specific parameters, and movement rules.

|

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1