|

设计描述:

文档包括:

word说明书一份,共39页,约18000字

CAD版本图纸,共3张

摘 要

破碎粉磨机械是冶金、矿山、电力、轻工、陶瓷、水泥、建筑和筑路等工业部门广泛应用的重要设备。破碎粉磨作业在国民经济中占有重要的地位,每年有大量的原料和再利用的废料都需要用破碎粉磨机械进行加工处理,且逐年增加。

因此,随着现代工业和科学技术的不断发展,同时也促进了破碎粉磨机械的发展,相继研制出了细碎、超细碎破碎机、惯性振动破碎机、振动磨机和立式搅拌机等高效新型破碎粉磨设备。

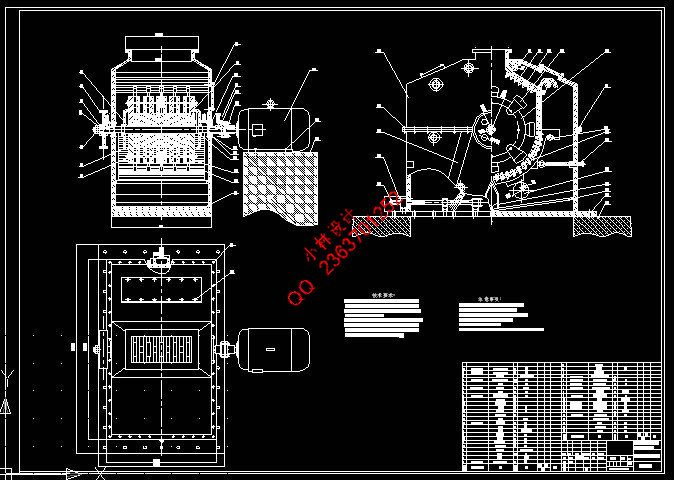

为了使破碎粉磨机械更有效的使用和促进其进一步发展,本次设计对它们的机构、工作原理和参数进行了设计计算。该破碎机的规格为Ф1000×1000,破碎物料为煤,最大破碎颗粒直径80mm。

关键词:破碎机;粉磨;煤;矿山;机械

Abstract

Broken powder mill machinery is the important equipment of industry department extensive uses such as metallurgy, mine, power, light industry, pottery and porcelain, cement, building and builds a road etc。 The broken powder mill school assignment owns the important position in national economy, and has mass raw material and waste material which used again all to need process the processing with broken powder mill machinery in every year, and just increases year by year。

Therefore along with constantly developing of modern industry and science and technology, also promoted at the same time the development of broken powder mill machinery, and developed out in succession in small, broken bits and the new broken powder mill equipment of machine and vertical mixer effect equal in height are ground in super in small, broken bits crusher, inertia vibration crusher and vibration。

In order to make broken powder mill machinery more actively uses and promotes his to develop further, and the organization, work principle and parameter to them of this design has carried on the design counting。 The specifications of this crusher is expected for the coal for 1000×1000, thing smashing something to pieces, fully broken anything small and roundish diameter 80mm。

Keyword:crusher;powder;Broken;crusher;min ehill;machinery

目 录

第1章 绪论 1

第2章 破碎机概述 2

2.1 破碎及力学特性 2

2.2 破碎产品的粒度分析 3

2.3 锤式破碎机的发展状况 4

2.4 破碎机的分类及应用 4

2.5 锤式破碎机的工作原理及特点 6

第3章 可逆锤式破碎机主要参数的设计与计算 8

3.1 可逆锤式破碎机结构设计 8

3.1.1 总体结构设计 8

3.1.2 篦条和冲击板的设计 10

3.1.3 转子的平衡问题 11

3.1.4 安全保护装置 11

3.1.5 锤头与篦条间隙调整机构 12

3.2 主要结构参数的选择与计算 12

3.2.1 转子直径与长度 12

3.2.2 给料口宽度与长度 12

3.2.3 排料口尺寸 13

3.2.4 锤头质量的计算 13

3.3 主要工作参数的设计计算 14

3.3.1 转子转速的计算 14

3.3.2 生产率的计算 14

3.3.3 电机功率的计算 15

第4章 可逆锤式破碎机的设计计算 16

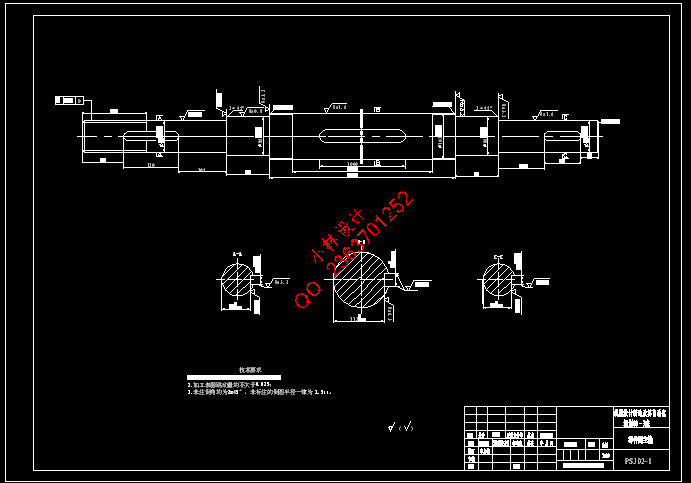

4.1 轴的设计 16

4.2 轴承的设计 18

4.3 联轴器的设计 20

4.4 键的选择 20

4.5 电动机的选择 21

4.5.1 根据使用负荷情况,选择电动机的功率 21

4.5.2 根据工作机械的转速要求以及传动方式选择电动机 21

4.5.3 根据电动机的铭牌选择电动机 22

4.5.4 根据电动机安装地环境来选择电动机的防护型式 22

4.5.5 电动机的安装 23

4.5.6 电动机的安全操作 23

4.5.7 电动机的维护 24

第5章 可逆锤式破碎机的安装与维护 26

5.1 可逆锤式破碎机的安装 26

5.2 可逆锤式破碎机的试车 26

5.3 可逆锤式破碎机的使用与维护 27

5.3.1 使用与致意事项 27

5.3.2 作好开车前的准备 28

5.3.3 运转中的使用和定时检查 28

第6章 经济分析 29

结 论 30

致 谢 31

参考文献 32

CONTENTS

Abstract I

Abstract II

Chapter1 Introduction 1

Chapter2 Crusher overview 2

2.1 Crushing and mechanical properties 2

2.2 The crushed product size analysis 2

2.3 The development of crusher 3

2.4 Classification of crusher and its application 4

2.5 Hammer type crusher working principle and characteristics 5

Chapter 3 Reversible hammer crusher design calculation of main parameters 7

3.1 Reversible hammer crusher structure design 7

3.1.1 The overall structural design 7

3.1.2 The grate and impact plate design 9

3.1.3 The balance problem of rotor 9

3.1.4 Safety protection device 9

3.1.5 The hammer head and the grate bars gap adjusting mechanism 10

3.2 Main structure parameter selection and calculation 10

3.2.1 Rotor diameter and length 10

3.2.2 Feeding mouth width and length 10

3.2.3 Outlet size 10

3.2.4 The hammer mass calculation 11

3.3 Main parameters design calculation 11

3.3.1 Rotor speed calculation 11

3.3.2 Productivity calculation 12

3.3.3 Motor power calculation 12

Chapter 4 Reversible hammer crusher design and calculation 14

4.1 Shaft design 14

4.2 Bearing design 15

4.3 Coupling design 16

4.4 Bond option 17

4.5 The choice of motor 17

4.5.1 According to the use of load conditions, the selection of motor power 17

4.5.2 According to the working machine speed requirements and transmission mode selection of motor 18

4.5.3 According to the motor nameplate selection of motor 18

4.5.4 According to the motor installation environment to the selection of motor protection type.....................................................................19

4.5.5 The motor mount 19

4.5.6 Motor safety operation 20

4.5.7 The maintenance of motor 20

Chapter 5 Reversible hammer crusher installation and maintenance 22

5.1 Reversible hammer crusher installation 22

5.2 Reversible hammer crusher test 22

5.3 Reversible hammer crusher maintenance 22

5.3.1 Use and salutations matter 23

5.3.2 Make preparations before driving 23

5.3.3 The use and timing check 23

Chapter 6 Economic analysis 25

Conclusion 26

Thanks 27

Reference 28

|