|

设计简介 |

设计描述:

文档包括:

word说明书一份,共41页,约15000字

CAD版本图纸,共8张

SolidWorks三维图,一套

目 录

中文摘要(关键词) 1

英文摘要(关键词) 2

1前言 3

1 .1阀门概况 3

1.1.1阀门行业技术水平 3

1.1.2 国外阀门行业最新发展动向 4

1.2蝶阀 4

1.2.1蝶阀的发展 5

1.2.2蝶阀的结构特性 5

1.2.3阀门的性能和系统要求 6

1.2.4中线蝶阀 6

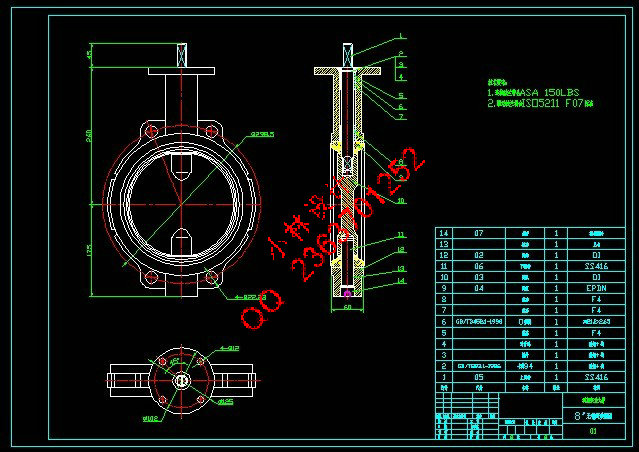

2 凸耳式中线无销蝶阀 7

3凸耳式中线无销蝶阀的总体设计 8

3.1设计的基本要求: 8

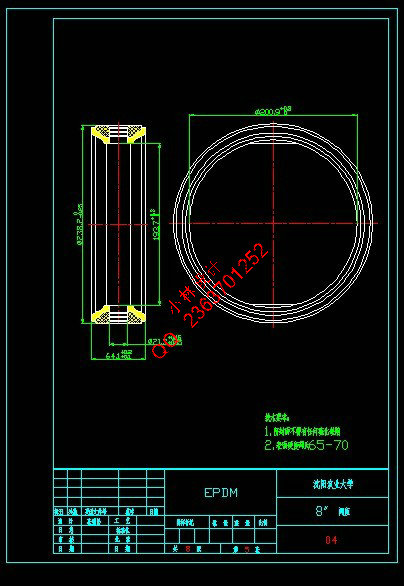

3.3阀座的设计与选择 9

3.4阀轴、阀板、阀体结构的选择 10

3.5凸耳式中线无销蝶阀的设计特点: 11

4中线无销蝶阀实体建模 12

4.1中线无销蝶阀建模过程 12

4.2中线无销蝶阀装配体及各部分零件 12

5中线无销蝶阀设计计算 17

5.1基本参数 17

5.2中线无销蝶阀典型计算 17

5.3轴的强度校核 26

6结论 27

参考文献 28

致 谢 29

摘 要

中线无销蝶阀是蝶阀中的一种,其主要特点就是阀轴与蝶板间的联结不需要用销联结,这种蝶阀结构简单紧凑,而且在很大程度上方便阀板的维修与拆卸(可现场拆装),并且无销蝶阀集成了蝶阀的一贯优点,无销蝶发不仅结构简单、体积小、重量轻、材料耗用省,安装尺寸小,而且驱动力矩小,操作简便、迅速,并且还可同时具有良好的流量调节功能和关闭密封性能。

在国内外蝶阀发展现状的基础上,利用Solidworks的从底至顶和从底至顶相结合的思想完成了中线无销蝶阀的实体建模、干涉检查和运动仿真,并对其组成零件进行了最优方案的选择和零件强度的校核,进一步完善了中线无销蝶阀的结构。选择了全橡胶有骨架阀座,增强了阀门的扭矩稳定性,阀门装配容易,端面采用凸台式, 以消除管道法兰压力对密封面的影响,安装和粘结于阀体后与阀体吻合性好, 尺寸控制稳定 ,密封副采用平面阀座与圆弧蝶板接触的型式, 摩擦力矩小,密封性能好。阀板设计成铁饼形状,阀板较薄,使得流量系数大,流阻小。所设计的阀门能够达到密封性能好,介质流通性能良好,装置可靠性高的设计要求。

关键词:中线无销蝶阀;发展现状;结构设计;建模;密封性能

Abstract

Center line butterfly valve without pin is one of butterfly valve, the main characteristics of it is the link between valve shaft and valve plate does not need to link with marketing,this kind of butterfly structure is Simple and compact,and to a great extent, the repair and demolition of valve is convenient(Disassemblage could be done at the scene),and center line butterfly valve without pin involves consistent advantage of butterfly valve, center line butterfly valve without pin is Not only has a simple structure, small value, light weight,and the consumption of material is saving, installation size is small,but also has a small driving torque,its operation is simple and rapid,and it can possess good flow and good closure of the sealing performance at the same time.

In the basis of the development of domestic and foreign butterfly valve,we can use the method of SolidWorks’ topdown and downtop together to achieve the solid modeling, interference detection and motion simulation of center line butterfly valve without pin,we can also achieve the best choice of program and the checking of parts intensity of its component parts,this perfected the frame of center line butterfly valve without pin further.We’ve chosen skeleton-wide rubber seat,this enhanced the valve’s torque stability, valve’s assemblyment becomes easy,its end panel uses convex desktop,we use these methods to remove pipe flange’s pressure which affects sealing surface, skeleton-wide rubber seat is installated and bonded to valve’s back so that there is good anastomosis of valve and it, the control of size is stability, vice-sealed uses butterfly valve with circular flat plate of the type of contact, friction torque is small, sealing performance is good. The valve is designed to the shape of discus, plate valve is thin,this makes flow coefficient large, flow resistance small.The designed valve could achieve design requirements of good sealing performance,good medium flow performance and high device reliability.

Key words: center line butterfly valve;development;structural design;Modeling;sealing performance

|