|

设计简介 |

设计描述:

文档包括:

word说明书一份,共38页,约16000字

CAD版本图纸,共4张

摘 要

本文讨论了在现有的加工条件下完成对液压缸套内孔的加工,即深孔加工,提出了车床改造的方案。简单介绍了深孔的发展概况、深孔加工系统的组成、深孔加工系统中的常用装置、深孔加工中的常见问题。至今,深孔加工机床甚少,普通车床不具有加工深孔的功能,因此,将普通车床C620-1改装为深孔加工机床,具有深远的意义。

关键词: 深孔加工; 车床改装; 进给机构; 钻削

Abstract

This article discussed in the existing processing conditions of hydraulic cylinder liner completed in the hole processing, namely the deep hole processing, puts forward the lathe reforming scheme. Briefly introduces the general situation of the deep hole, deep hole processing system composition, deep hole processing system of common device, deep hole processing of common problem. So far, the deep hole processing machine tool little, ordinary lathe don't have the function of the deep hole processing, therefore, the ordinary lathe C620-1 modified for the deep hole processing machine tools and has far-reaching significance.

Key words: the deep hole processing ; lathe transformation ; feed mechanism ; drilling

目 录

摘 要 I

Abstract II

目 录 III

CONTENTS V

第1章 绪论 1

1.1深孔加工机床的研究意义 1

1.2国内外发展状况和趋势 1

1.3深孔加工技术研究概述 3

1.3.1深孔的定义 3

1.3.2深孔加工的类型、特点及要解决的主要问题 4

1.3.3常用深孔加工系统 6

1.3.4深孔加工方法及机理的研究 7

1.3.5深孔加工刀具的研究 9

1.4深孔的镗滚压加工 9

1.4.1深孔镗削加工 9

1.4.2深孔滚压加工 11

第2章 深孔加工机床总体设计的理论分析 14

2.1 工艺方案和工艺路线的制定 14

2.2 总体设计 15

2.2.1总体设计内容 15

2.2.2深孔加工要求 16

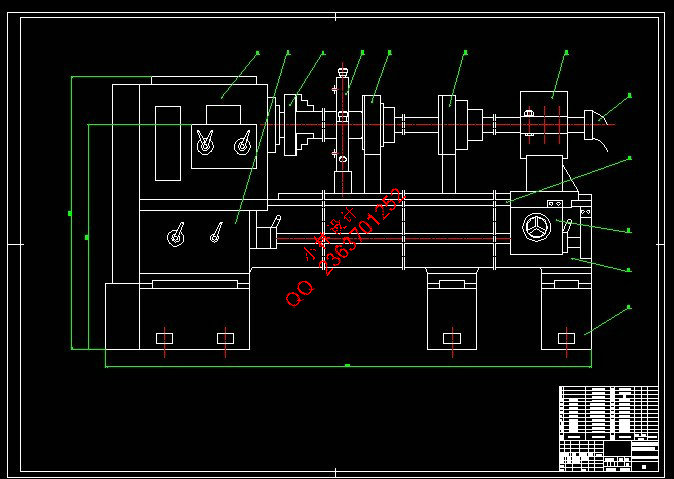

2.2.3车床设计总体方案 17

第3章 深孔加工工装设计 19

3.1 机床主要部件的功能 19

3.1.1床身 19

3.1.2主轴箱 19

3.1.3前、后受油器 19

3.1.4前、后拖板 20

3.1.5冷却排削系统 20

3.2 机床设计分析与计算 20

3.2.1车床型号的选择 20

3.2.2主要设计参数和技术要求 21

3.2.3钻削力,钻削功率的计算 21

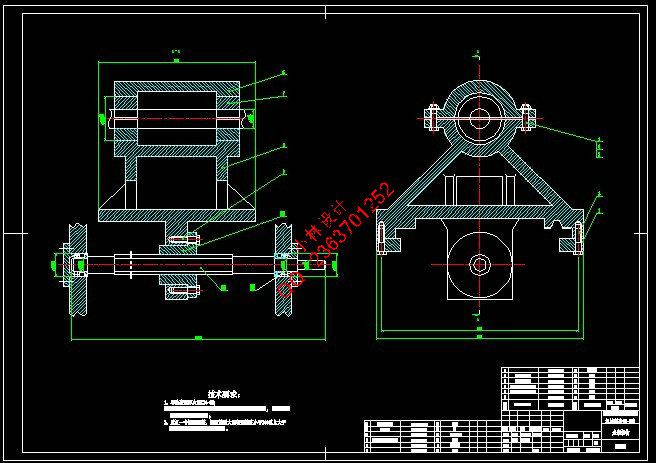

第4章 定位、夹紧装置设计 22

4.1 总体方案设计 22

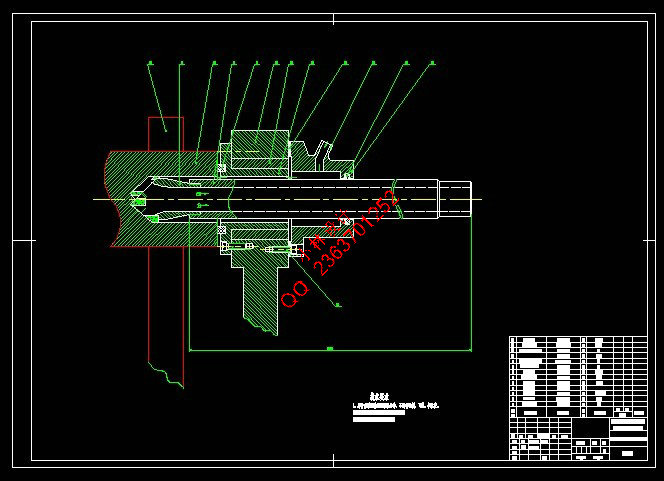

4.2 夹紧装置设计 22

4.2.1 夹瓦强度校核 23

4.2.2 钻杆固定架设计 24

4.2.3 弹簧设计 25

4.2.4 压板设计 27

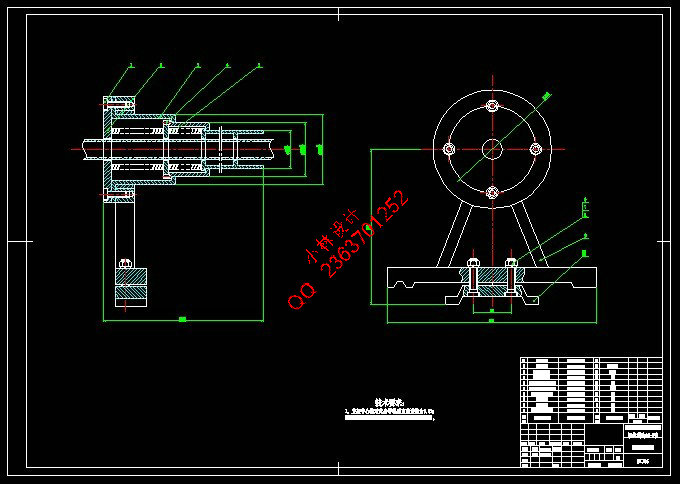

4.3 授油器的结构设计 28

结 论 30

致 谢 31

参考文献 32

CONTENTS

Abstract I

Abstract II

CONTENTS III

Chapter 1 Introduction 1

1.1 The deep hole processing machine tool’s research significance 1

1.2 The domestic and foreign development status and trends 1

1.3 The deep hole processing technology research overview 3

1.3.1 Definition of deep hole 3

1.3.2 Commonly used the deep hole processing system 4

1.3.3 The deep hole processing cutting tool 6

1.3.4 Deep hole cut features bore 7

1.3.5 Deep hole rolling processing characeteristics 9

1.4 Deep hole boring and rolling processing 9

1.4.1 Deep hole boring processing 9

1.4.2 Deep hole rolling processing 11

Chapter 2 The deep hole processing machine the overall design of the analysis 14

2.1 Technical scheme and the formulation 14

2.2 The overall design scheme 15

2.2.1 General design content 15

2.2.2 Deep hole processing requirements 16

2.2.3 Lathe overall design scheme 17

Chapter 3 The deep hole processing equipment design 19

3.1 The function of the main components of the machine tool 19

3.1.1 Lathe bed 19

3.1.2 Spindle box 19

3.1.3 By oli,before and after 19

3.1.4 Dragging plate,before and after 20

3.1.5 Cooling scraps discharge system 20

3.2 Machine design analysis and calculation 20

3.2.1 Lathe model choice 20

3.2.2 The main design parameters and technical requirements 21

3.2.3 Drillng force.Drilling the calculation of power 21

Chapter 4 Positioning,clamping device design 22

4.1 The general scheme design 22

4.2 Clamping device design 22

4.2.1 Clip tile intensity 23

4.2.2 Drill pipe fixed frame is designed. 24

4.2.3 Spring design 25

4.2.4 Linking piece design 27

4.3 The construction design by oil 28

Conclusion 30

Thanks 31

References 32

|