|

|

|

|

设计名称 |

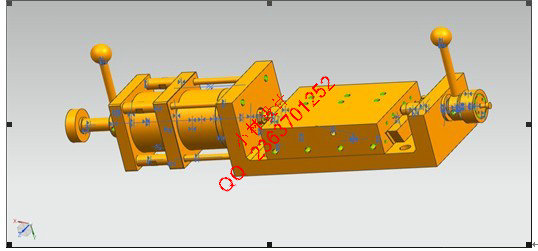

轴承内外圈加工专用机床纵向机构设计[UG三维] |

|

|

设计编号 |

Z217 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

19000字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

2013.09.26 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

设计描述:

文档包括:

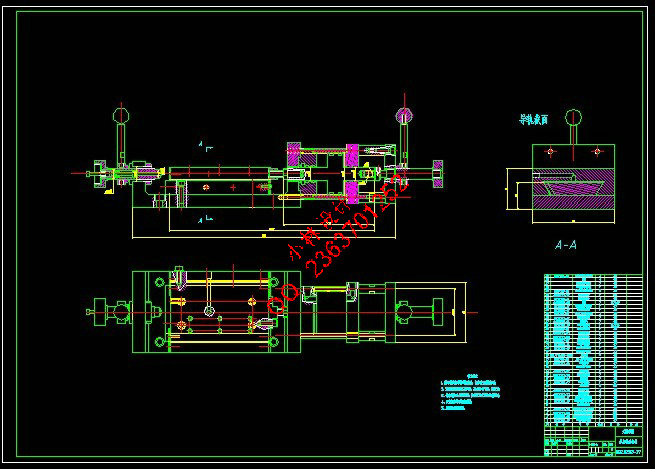

CAD版本图纸,共27张

中的一项关键因素,而车床的进给机构直接影响轴承套圈加工的尺寸精度。因此,随着对轴承质量要求的不

断提高,需要更加精密高效的车床进给机构。 低,生产出的零件精度难于控制的问题,设计一套此车床的半自动进给机构,代替传统机床的人工操作,提

高生产效率,提高零件的精度。 ,前、后调节机构调节进给量的纵向进给机构。本文先对液压驱动系统、导向机构、前调节机构、后调节机 构进行设计,确定具体尺寸。利用UG软件对纵向进给机构进行三维建模,并进行虚拟装配。然后对装配图在 UG运动仿真界面进行运动仿真,分析仿真结果,得出相应结论。最后对纵向进给系统进行优化设计,提高其 稳定性、可靠性。使其能满足轴承厂生产线繁重的工作。

关键词:进给机构;UG;虚拟装配;运动仿真 With the rapid development of bearing industry, the working accuracy, efficiency and reliability of bearing have been put forward higher requirements.A essential factor of bearing process is the dimensional accuracy, however, the feeding system of machine tools directly affects the dimensional precision of bearing ring process. Therefore, with the constant improvement of bearing's quality requirements, it is necessary for the feeding system of

machine tools to become more precise and efficient. project in bearing factory. As the process efficiency is low by the manual control of the machine feed process and the precision of the parts production is difficult to control. This paper designs a lathe of semi-automatic feed mechanism to instead of manual operation of

conventional machines, in order to improve production efficiency and the part accuracy. characteristic of feed processing by bearing inner and outer rings process equipment. The aim of this paper is designing a longitudinal feed mechanism through using hydraulic drive, before and after the vertical regulating mechanism adjust the feed. The paper devises a process equipment what is using hydraulic drive and before and after the adjustment mechanism to adjust the feed rate and after that identifies a specific size. This paper uses UG software for proceeding 3D modeling of longitudinal feed mechanism and virtual assembly, after that carries out on the motion simulation by assembly drawings in UG motion simulation interface and analysis of the simulation results, and ultimately obtains the corresponding results. Finally, the paper optimizes the design for the longitudinal of feed system, improving the stability and reliability, which is for meeting heavy work of the production line in bearing factory. Key words: feed mechanism; UG; virtual assembly; motion simulation

|

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1