|

设计简介 |

设计描述:

文档包括:

word说明书一份,共47页,约19000字

任务书一份

开题报告一份

外文翻译一套

CAD版本图纸,共4张

摘 要

气电立焊是由普通熔化极气体保护焊和电渣焊发展而形成的一种熔化极气体保护电弧焊方法,焊接效率及焊接质量均较高,主要应用于船舶的外壳板的中厚板焊接,也可应用于相应尺寸的桥梁箱式梁腹板及大型储罐侧板的中厚板的焊接。为了提高快速响应能力,必须实现快速虚拟设计。

本论文首先介绍了气电立焊机,包括它的原理、特点、工艺特点,并介绍了其设备和用途,详细介绍了船体气电自动立焊机。

其次,我们完成了丝杆的三维建模。另外,为了应对繁多的齿轮传动,我们专门开发了PRO/E参数化齿轮建模方法,完成了参数化齿轮建模。综合运用PRO/ENGINEER软件、CAXA软件、AUTOCAD软件,我们完成了轴承三维模型的创建。利用PRO/E的零件族表功能,我们完成了大量标准件的三维建模,诸如轴承、螺栓、垫片、螺帽等等。

然后,我们在PRO/E中进行机构运动仿真,介绍一些具有代表性的装配过程,这些装配过程用到了一些实用的装配技巧。我们介绍了基本装配约束,多个螺栓的重复性装配,链条的阵列化装配,装配件中的改名操作,轴组件的装配。

最后,我们进行了机构运动虚拟设计。把各个零部件通过装配模块组装成一个完整的机构后,在PRO/E中直接启动机构运动分析模块,定义机构中的连接,设置伺服电机,分析运行机构,观察机构的整体运动轨迹和各零件之间的相对运动,进行运动仿真举例,最终能将机构运动录制成JPEG格式的动画。

关键词:气电立焊;三维建模;虚拟设计;仿真

Abstract

Electro-gas welding is a kind of melting by the ordinary gas metal arc welding and electro-slag welding development and the formation of polar gas shielded arc welding method, welding efficiency and welding quality is high, thick plate welding of the shell plate is mainly applied to the ship, but also can be applied to the corresponding size of bridge box girder webs and large storage tank side welding of plate. In order to improve the rapid response capability, to achieve rapid virtual design.

This paper firstly introduces the electro-gas welding machine, including the principle, characteristics, its process characteristics, and introduces the equipment and use, details of the ship body electric automatic vertical welding machine.

Secondly, we completed the three-dimensional modeling of wire rod. In addition, in order to deal with various kinds of gear transmission, we specializes in the development of gear parametric modeling method of PRO\/E, the parametric modeling of gear. Comprehensive use of PRO\/ENGINEER software, CAXA software, AUTOCAD software, we completed the creation of three-dimensional model of bearing. With the family table function parts of PRO\/E, we completed the three-dimensional modeling of many standard parts, such as bearings, bolts, gaskets, nut etc..

Then, we performed the mechanism movement simulation in PRO\/E, introduces some representative assembly, the assembly process to use some practical assembly skills. We introduced the basic assembly constraints, repeated assembly of a plurality of bolt, chain array assembly, assembly of renaming operation, shaft assembly.

Finally, we carried out the movement of virtual design. The assembled into a complete mechanism of each parts of the assembly module, direct start mechanism motion in PRO\/E analysis module, connect definition mechanism, a servo motor is arranged, analysis of the operation mechanism, the relative movement between the overall trajectory of institutions and all parts of the simulation exercise, for example, can finally mechanism motion records into JPEG format animation.

Keywords:electro-gas welding; 3D modeling; virtual design; simulation

目 录

摘 要 IV

ABSTRACT V

目 录 V

1 绪论 1

1.1本课题的研究内容和意义 1

1.2国内外的发展概况 1

1.3本课题应达到的要求 3

2 气电立焊机介绍 4

2.1气电立焊的原理 4

2.2气电立焊的特点 4

2.3气电立焊工艺特点 5

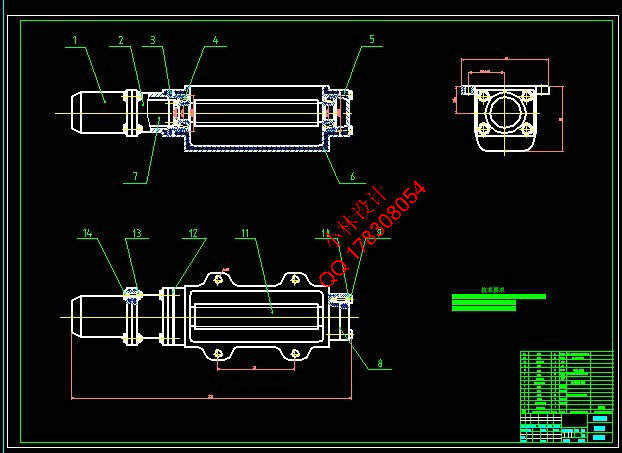

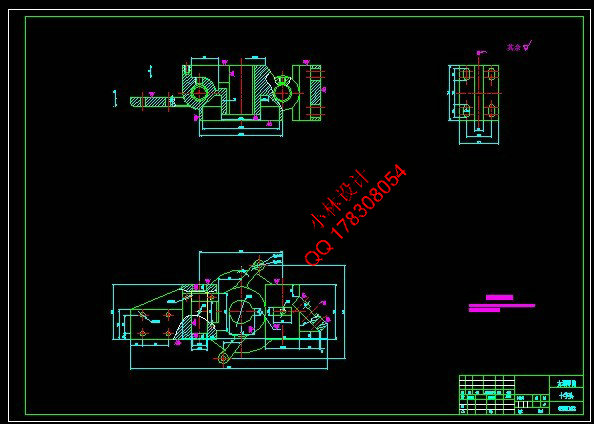

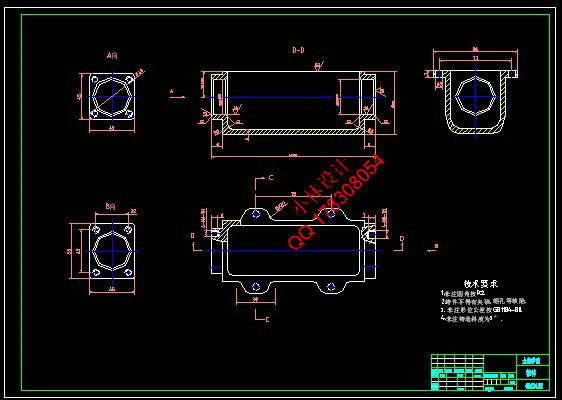

2.4气电立焊设备介绍 7

3 主要零部件建模 9

3.1丝杠的三维建模 9

3.2参数化齿轮建模 11

3.3轴承三维模型的创建 16

3.4垫片的创建 19

4 零部件虚拟装配 22

4.1基本装配约束介绍 22

4.2多个螺栓的重复性装配 22

4.3链条的阵列化装配 24

4.4装配件中的改名操作 25

4.5 轴组件的装配 25

5 机构运动虚拟设计 27

5.1机构运动虚拟设计功能概述 27

5.1.1机构运动虚拟设计功能概述 27

5.1.2机构运动虚拟设计功能的一般步骤 27

5.2连接定义 27

5.3定义伺服电机 28

5.4创建运动分析 28

5.5运动仿真举例 29

5.5.1定义链条运动 29

5.5.2定义丝杠传动 30

6 结论与展望 33

致 谢 34

参考文献 35

|