|

设计简介 |

设计描述:

文档包括:

word说明书一份,共33页,约7500字

任务书一份

开题报告一份

外文翻译一份

CAD版本图纸,共6张

PROE三维图纸一套

摘 要

机械设计在国民经济发展中起着重要作用,机械工业担负着为国民经济部门提供各种性能先进,价格低廉,使用安全可靠,造型美观的技术装备的任务,在国家现代化建设中举足轻重,机械产品的竞争力取决于产品的质量,产品的质量取决于产品的设计。

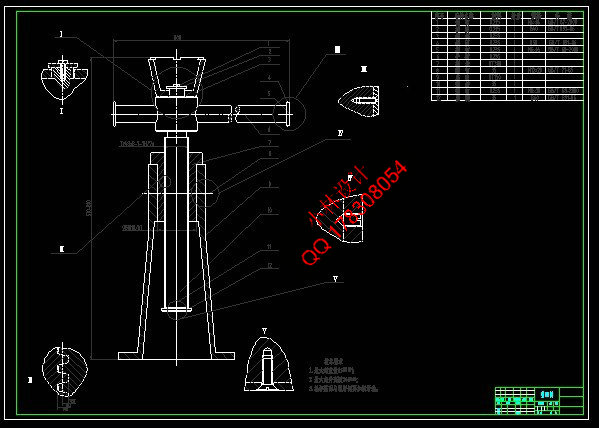

螺旋千斤顶是一种起重高度小(小于1m)的最简单的设备。主要用于矿、交通运输部门作为车辆修理及其它起重、支撑等工作。其结构轻巧坚固、灵活可靠,一人即可携带和操作。千斤顶是用刚性顶举件作为工作装置,通过顶部托座,底部托爪在小行程内顶升重物的轻小起重设备。 该千斤顶是手动起重工具种类之一,其结构紧凑,合理的使用摇杆的摆动,使小齿轮转动,经一对圆锥齿轮啮合运转,带动螺杆旋转,推动升降套筒,从而使重物上升或下降。

设计既是产品开发周期中关键的环节,又贯穿于产品开发过称的始终,设计决定了产品功能和目标的方案,结构和选材,制造方法以及产品运行,使用和维修方法。设计不合理会导致产品不完善,成本提高或可靠性、安全性不高。产品设计上的缺陷造成的先天不足,难以采取制造和使用措施加以弥补。严重的设计不合理甚至会造成产品设计不出来或不能使用,导致产品设计失败。

本次设计中,我首先查阅了大量资料,确定了将要设计的千斤顶结构,了解了零件的组成,和运行原理,然后通过计算得出了结构数据,再通过CAD作出相关图形,使用PROE作出三维图,再进行了运动仿真,进而得出成果。

关键词:机械设计;螺旋千斤顶;设计计算;运动仿真。

Abstract

As is known to all, mechanical layout plays an important role in our daily national economy.Mechanical industry undertakes the task that improve the capability-advanced,low-price,safety,and good-looking equipment in the part of national economy.The advantage of the mechanical equipment is of the quality of machine,And the quality of machine depends on the mechanical layout.

The screw jack is a machine which has low lifting height.It is used for lifting and sustain in the repairing of cars in traffic and mining industry.As the structure of screw jack is stong and flexible,it can be carried and operated by a single person.It is made up of rigid lifting device.By using the top bracket and the bottom drag claw,one can lift something in a short distance.This jack is a part of HM-lifting equipment.With the compact structure,one can lift the heavy things by swing reasonable distance of the jointed arm to make the wheel gear move to enable the screw revolving.

This layout is not only a important part of the product development cycle,but also run through from the beginning to the end of the development of the product.The layout make sense of the function and plan,structure and material selecting,manufacturing methods and product operation,and using and repairing.Unreasonable design may result in the imperfect of product and adding in the cost.It also may influence the safety and reliability.It is hard to make up by using the method of producing and using,if the machine has defect in design.What`s more,it may result in the fail of the layout.

At first,I refered to large quantities of documents,so that made sure of the structure of screw jack.With these documents,I understood the comprise of the components,and the original principle of how it works.Then, by calculating,I worked out the structure of its data.After calculating,I carried out this case by drawing out the graphic models and doing motion simulation by PROE after working out the related figures by CAD.

The keyword: machine design ; screw jack ; design operation ; motion simulation

目 录

摘 要 III

ABSTRACT IV

目 录 VII

1 绪论 1

1.1本课题的研究内容和意义 1

1.2国内外的发展概况 1

1.3本课题应达到的要求 2

2螺旋千斤顶的概述和设计要求 3

3螺旋千斤顶各部分的设计与计算 5

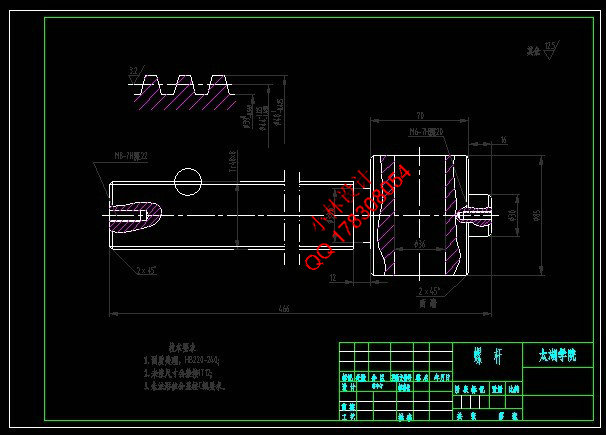

3.1 螺杆的计算 5

3.1.1 螺杆螺纹类型的选择 5

3.1.2 选取螺杆材料 5

3.1.3 螺杆的直径 5

3.1.4 自锁性验算 7

3.1.5 螺杆结构 7

3.1.6 稳定性计算 7

3.2 螺母的设计计算 8

3.2.1 螺母的材料 8

3.2.2 确定螺纹旋合圈数 8

3.2.4 螺母其它结构尺寸 9

3.2.5 螺母外径和凸缘强度的计算及螺母悬置部分校核 9

3.3托杯的设计计算 11

3.3.1 验算接触面间的压力强度 11

3.3.2 托杯的外口径 11

3.4 手柄的设计计算 11

3.4.1 手柄材料 12

3.4.2 手柄长度 12

3.4.3 手柄直径 12

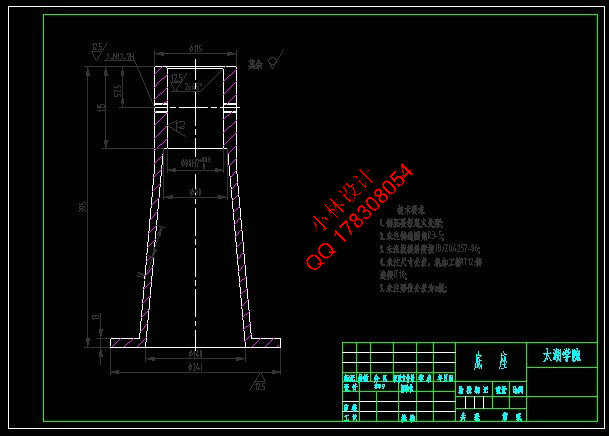

3.5 底座的设计计算 13

3.5.1 底座材料 13

3.5.2 其主要结构尺寸 13

3.6 千斤顶的效率计算及绘制CAD图纸 14

4 基于PRO/E的千斤顶仿真 15

4.1千斤顶主要零件的三维建模 15

4.2千斤顶的装配设计 24

4.3仿真分析 27

5结论与展望 31

5.1结论 31

5.2不足与展望 31

致谢 33

参考文献 35

附录 37

|