|

设计简介 |

设计描述:

文档包括:

word说明书一份,共42页,约24000字

任务书一份

开题报告一份

外文翻译一份

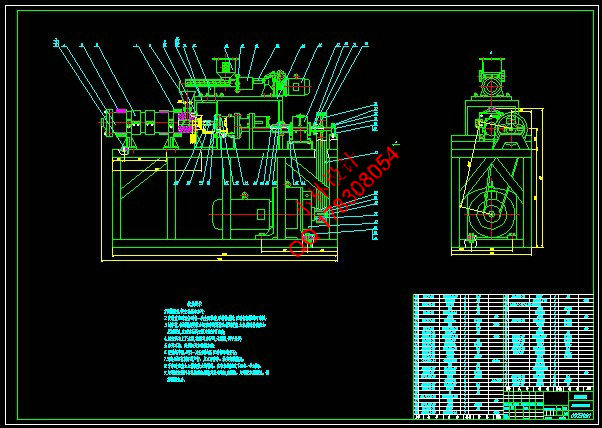

CAD版本图纸,共6张

摘 要

本文先分析了鱼肉仿真食品市场需求和生产现状,通过对仿真虾仁的分析以及与传统加工工艺的对比从理论上来验证采用挤压机鱼肉仿真食品的工艺可行性和经济可行性。其次,分析单螺杆挤压机与双螺杆挤压机的特点以及生产工艺的需要,确定了先通过单螺杆挤压机进行蒸煮、搅拌,再用双螺杆挤压成型机成型的生产流程。在现有挤压机的基础上,并参考了国内外比较成熟的挤压机设计方法,根据鱼肉仿真食品的的特殊工艺要求,对挤压机的关键部位进行了相应的改进。本文详细的介绍了挤压机的主要零部件分配箱、螺杆、机筒等的结构设计,并进行了相应的校核计算;对主要传动零部件如分配箱大小齿轮,带轮、从动轴、键等进行了设计和强度校核,并对轴承承载能力、寿命进行了校核计算;本文还涉及了挤压机一些辅助元件如加料系统、加热冷却装置、模头装置的选择要求,并进行了简单的设计。最后,本文介绍了一些关于挤压机的安装、操作、控制和维护等方面的内容。

关键词:鱼肉仿真食品;双螺杆挤压机;加料系统;传动零部件

ABSTRACT

This article analyzed the food simulation market demand and the production present situation first, through analysis to the prawn cracker and as well as with the traditional processing craft contrast from the theory to use the extruder to produce the food craft feasibility and the economical feasibility. Next, analyzes the single screw rod extruder with the double screw rod extruder characteristic as well as the production craft need, had determined digestion and agitation through the single screw rod extruder first, then uses the double screw rod to extrude the shaper formation the production process. In the base of the extruders in existence, we referenced the mature means of extruder design in our country and abroad and the special working craftwork requires of the snack foods, then, we improved the key structure of extruder. In this text, we introduced the structure design of extruder in detail, particular to the major parts: assignment tank, screw, barrel and systems analysis and calculating. To those important transmission parts: the big gear and the small gears in assignment tank, strip wheel, driving spindle, key, we made a design and check the intensity. And we calculate and check the carrying capacity of the bearing particularly. We also refer to the choosing requirements of the accessories: heating and cooling system, die, knife equipment, and made a simple design. In the end of the text, the installing, operation, controlling and repairing of the extruder were also introduced.

Keywords: Fish food simulation;Twin-screw Extruder;charging system;Transmission parts

目 录

摘 要 III

ABSTRACT IV

目 录 V

1 绪论 1

1.1 项目背景及重要性 1

1.1.1 鱼肉仿真食品的市场需求 1

1.1.2 鱼肉仿真工程食品加工现状及分析 4

1.2 研究的主要内容 5

2 双螺杆挤压机设计 7

2.1 双螺杆挤压机的工作原理 7

2.2 挤压加工系统 7

2.2.1 挤压加工系统组成 7

2.2.2 常用挤压术语 7

2.3 双螺杆挤压机总体设计 8

2.3.1 总体结构设计 8

2.3.2 螺杆结构设计 8

2.3.3 机筒结构设计 12

2.3.4 加料系统 13

2.3.5 加热和冷却装置系统 13

2.3.6 模板装置 16

2.4 双螺杆挤压机挤压部件设计计算 16

2.4.1 主传动系统的确定 16

2.4.2 螺杆的强度计算 18

2.4.3 机筒结构的设计 19

2.4.4 模头结构设计 20

3 双螺杆挤压机的操作 25

3.1 双螺杆挤压机的安装 25

3.2 挤压加工系统的操作与维护 25

3.2.1 挤压机的开车 25

3.2.2 开车操作注意事项 25

3.2.3 挤压机维护保养 26

4 总结与展望 27

4.1 总结 27

4.2 展望 27

致 谢 29

参考文献 31

|