|

|

|

|

设计名称 |

围板包装箱自动生产线合围装置设计[ug三维] |

|

|

设计编号 |

Z283 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

23000字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

2013.10.26 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

设计描述:

文档包括:

word说明书一份,共47页,约23000字

任务书一份

开题报告一份

外文翻译一份

UG三维版本图纸,一套

摘 要

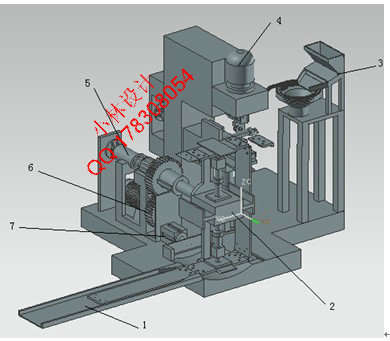

围板箱作为产品外包的物流设施,围板箱越来越受客户的欢迎,使用量巨大。然而,现有的围板箱生产方式落后,在生产中人为因素较大,这使得围板箱的生产上存在着生产效率低,质量不稳定等缺陷。这严重影响着围板箱的应用。为了提高劳动生产率,降低工人劳动强度,节约生产成本,我们对围板箱的现有生产工艺进行了研究,通过对原有围板箱生产工艺的分析,设计了适应于围板箱的自动合围装置。

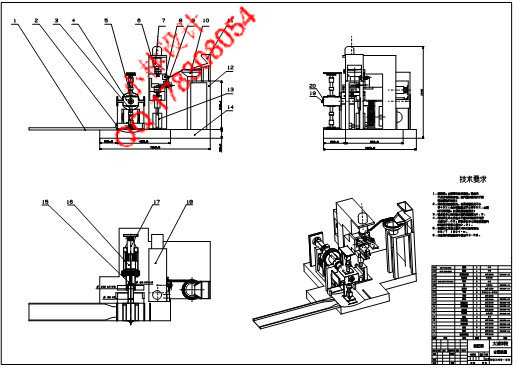

围板包装箱在生产过程中主要分为上料、拼接、钻铆、合围等几部分工序,本论文主要是设计合围装置的说明。将2个用铰链连起来的2片木板的两端分别铆接起来。连接起来的木板链一端是只有孔,另一端是仅铆接了半面铰链(另半面没有铆接)。首先第一步是铆接了半面铰链的一端在前另一端在后,通过挡板来约束定位;第二步运用气压缸来推动夹紧块来夹紧木板,使之不能像对滑动;之后在是夹紧装置绕主轴旋转180°,在重复第一、二步操作(第二次只旋转90°),使两块木板合围,之后通过平移夹紧旋转装置使需要铆接的部分移到铆接机上,在上铆钉铆接从而完成合围。

关键词:围板箱;合围;铆接;自动生产线

Abstract

Hoardings box as outsourcing logistics facilities around the crate more and more popular with customers , a huge amount of use . However, the backward the existing hoardings box mode of production in the production of man-made factors , which makes the production of hoardings box there is low productivity, unstable quality defects . This has seriously affected the application of hoardings box . In order to improve labor productivity, reduce labor intensity , reduce production costs , we conducted a research on the hoardings Box existing production process through the analysis of the production process of the original hoardings box , designed to adapt to the hoardings box automatically encirclement devices.

The hoardings box on materials , stitching, drilling and riveting , encircled in the production process is divided into several parts process of this thesis is the design of the encirclement device . Two hinges to link two of the ends of the planks were riveted . Connected one end of the wood chain is the only hole , the other end is only half a face riveted hinge ( the other half of a riveting ) . First step is riveting half-face one end of the hinge in front the other end of the baffle to constrain the positioning ; second step the use of pneumatic cylinder to push the clamping block for clamping wood , so they can not like sliding ; after clamping device around the spindle 180 ° , repeat the first and second steps ( second rotation only 90 ° ) , so that the two pieces of wood encircled by the pan after clamping rotary device to make part moved to the riveting machine riveting , thus completing the encirclement on the rivet .

Key words: Hoardings box ; encirclement ; riveting ; automated production lines

目 录

摘 要 III

ABSTRACT IV

目 录 V

1 绪论 1

1.1本课题的研究内容和意义 1

1.2国内外的发展概况 1

1.3 本文主要设计内容 4

2 生产线总体结构设计 5

2.1 围板箱生产工艺分析 5

2.1.1 围板尺寸参数 5

2.1.2 生产线工艺流程 5

2.1.3 总体结构 7

2.1.4 生产节拍的拟定 7

2.1.5 控制系统 8

3 各部分具体设计 9

3.1木料传入部分设计 9

3.2 木料的定位夹紧装置设计 9

3.3 旋转移位装置 10

3.3.1 电动机的选取 11

3.3.2 传动比的分配 13

3.4 伸缩移位 19

3.5 铆接 20

3.5.1 定位 20

3.5.2 送钉装置 20

3.5.3 铆接装置 29

4 结论与展望 35

致 谢 36

参考文献 37

|

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

声明:根据《互联网传播权保护条例》本站,小林机械资料商城,所列资料均属原创者所有,仅供学习交流之用,请勿转载并做其他非法用途。

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1