|

|

|

|

设计名称 |

三角带无极变速装置设计[sw三维] |

|

|

设计编号 |

v006 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

14000字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

2013.09.26 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

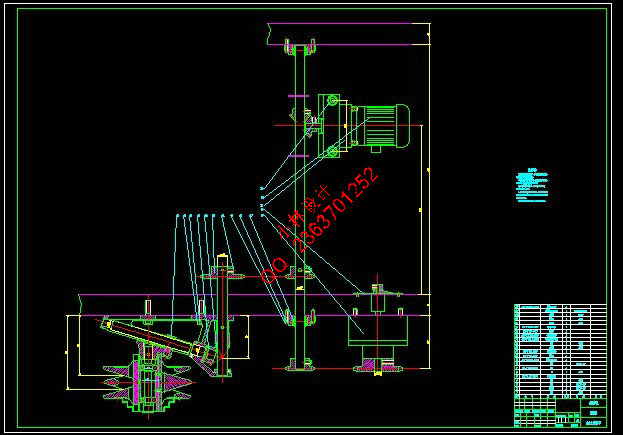

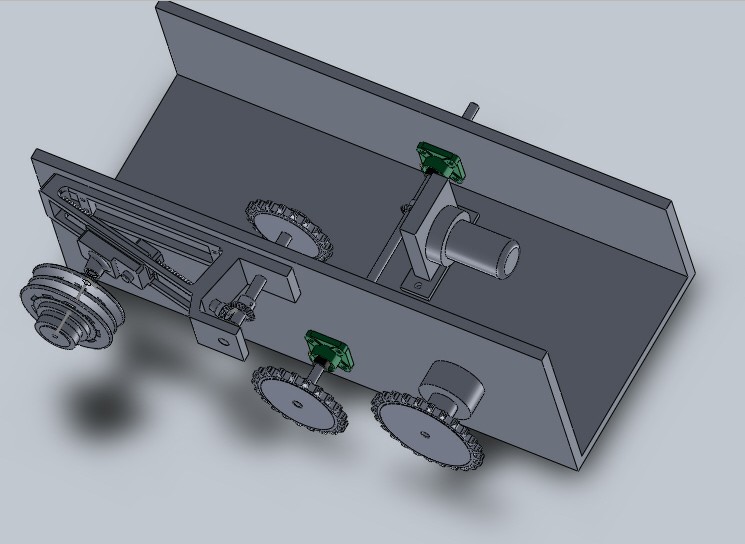

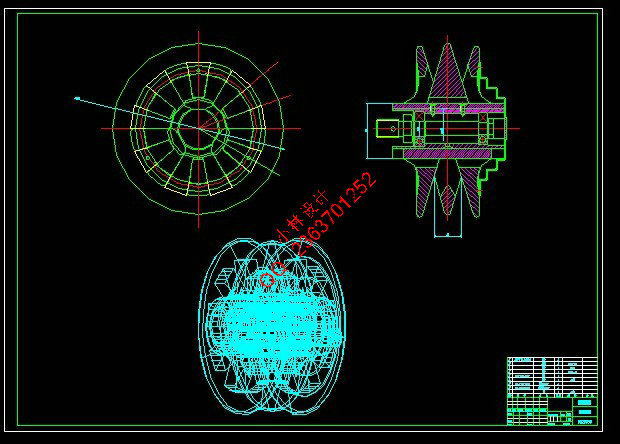

设计描述:

文档包括:

CAD版本图纸,共6张

改变,从而得到传动系与发动机工况的最佳匹配。常见的无级变速器有液力机械式无级变速器和金属带式无

级变速器。 传动比的变化方式又可分为有级式自动变速器和无级式自动变速器。因此,无级变速器实际上是自动变速器

的一种,但它比常见的自动变速器要复杂得多,技术上也更为先进。 有挡位的,它所能实现的是在两挡之间的无级变速,而无级变速器则是两组变速轮盘和一条传动带组成的, 比传统自动变速器结构简单,体积更小。另外,它可以自由改变传动比,从而实现全程无级变速,使车速变 化更为平稳,没有传统变速器换挡时那种“顿”的感觉。 关键字:无级变速器;自动变速器;齿轮变速

cooperated with the power to deliver, can realize the TRANSMISSION ratio of the continuous change, and get the TRANSMISSION and engine condition the best match between. Common step-less transmission have hydraulic mechanical step-less transmission and belt type step-less transmission , the current domestic market of the vehicles already more and more. Editor this

section step-less transmission and the origin of the automatic transmission. system, the control method, it can be divided into the hydraulic controlled hydraulic and electric automatic transmission hydraulic automatic transmission; According to the change of the transmission way and can be divided into have levels of automatic transmission and no levels of automatic transmission. Therefore, step-less transmission is actually a kind of automatic transmission, but it than common automatic transmission is much more complex, more advanced technologies. Step-less transmission and common hydraulic automatic transmission of the biggest differences is on the structure, the latter is by hydraulic control gear drive system structure, still have the gears, it can be realized in between the two block is continuously variable transmission , and is two groups plate and a belt speed of than traditional automatic transmission, simple structure, smaller. In addition, it is free to change gear ratios, so as to realize the full speed stepless speed change, make more smoothly, without the traditional transmission shift at the "" feeling. Editor this section step-less transmission classification. Key words:Stepless speed technology;Automatic transmission;reduce fatigue driving

|

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1