|

|

|

|

设计名称 |

卧式双面组合镗床及工装设计 |

|

|

设计编号 |

V013 | |

|

设计软件 |

AutoCAD, Word | |

|

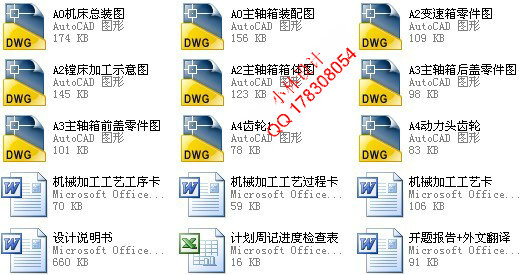

包含内容 |

见右侧图片 | |

|

说明字数 |

20000字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

2013.9.26 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

设计描述:

文档包括:

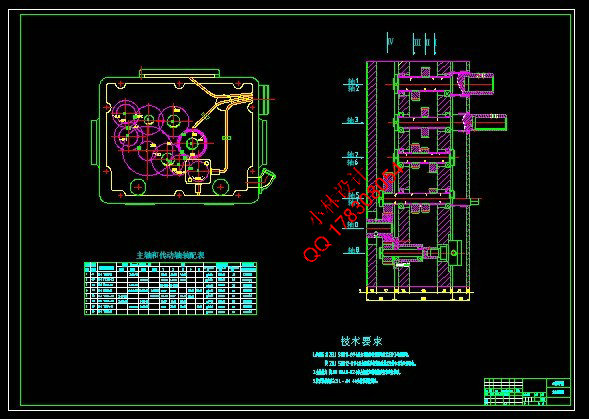

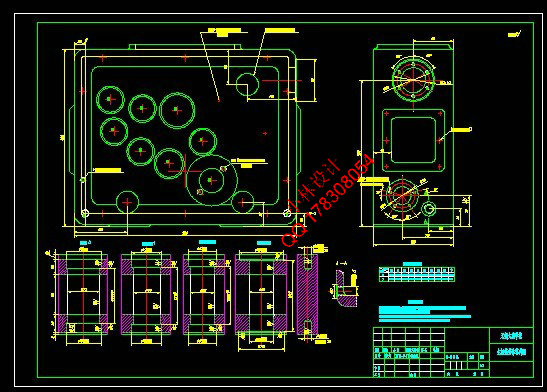

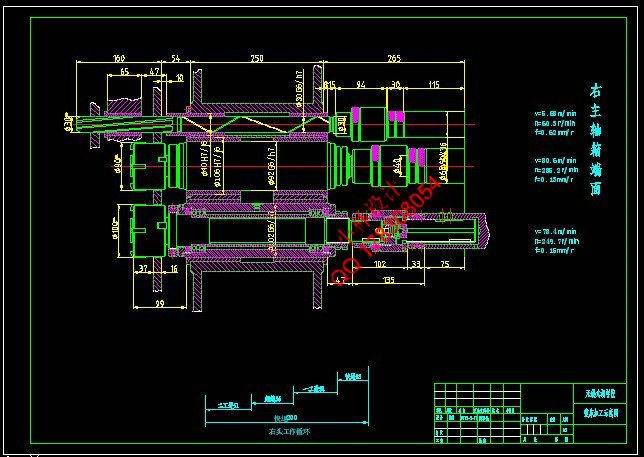

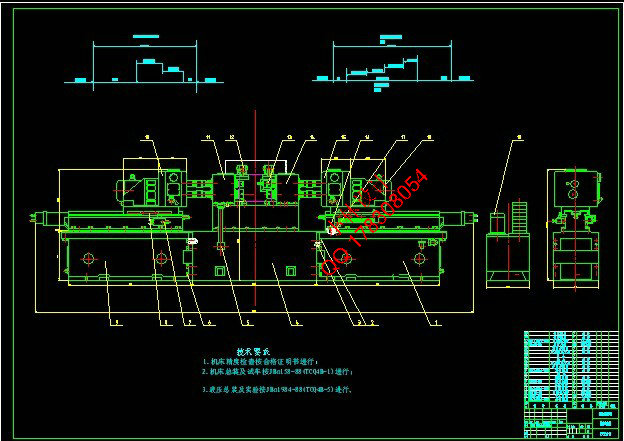

CAD版本图纸,共9张 摘 要 该篇论文为镗主轴箱的6个轴孔的变速箱组合镗床设计。镗床是主要用镗刀对工件已有的预制孔进行 镗削的机床。通常以镗刀旋转为主运动,镗刀或工件的移动为进给运动。它主要是用于加工高精度孔 或一次定位完成多个孔的精加工,此外还可以从事与孔精加工有关的其他加工面的加工。使用不同的 刀具和附件还可进行钻削、铣削、切削,其加工精度和表面质量要高于钻床。镗床是大型箱体零件加

工的主要设备,也可加工螺纹及外圆和端面等。 模、导套、台式铣镗床后立柱支承长镗杆或人工找正工件回转180°等方法实施长孔镗削的实例,但 近些年来,一方面由于数控铣镗床和加工中心的大量使用,使各类卧式铣镗床的坐标定位精度和工作 台回转分度精度有了较大提高。从机床结构上使工作台回转180°自定位的调头镗孔,几乎是成为了

在该种机床上镗削长孔的唯一方法。

以论述。 关键词:主轴箱;组合镗床;加工工艺

Gearbox combination boring lathe design this paper into 6 hole boring spindle box. Boring machine is mainly used for boring prefabricated holes on the workpiece has been the boring machine. Usually, boring cutter rotating main movement, the workpiece moving boring or for feed motion. It is mainly used for finishing machining high precision hole or a location to complete a plurality of holes, in addition to engage with the hole machining processing and other related processing surface.Different tools and accessories used can also be drilling, milling, cutting,, the machining precision and surface quality than that of drilling machine. Boring machine is the main equipment of large body parts processing. Can also be processed the thread and the outer circle and

end. of the most important content in the metal cutting. Although there are still using boring mode, guide sleeve, desktop milling and boring machine after the columns support the long boring bar or artificial alignment workpiece rotation of 180 DEG, examples of long hole boring. But in recent years, on the one hand because of the extensive use of CNC milling machine and machining center, precision of the coordinate positioning rotary precision and working table of horizontal boring and milling machine has been greatly improved. From the machine tool structure enable the rotary table 180 ° from the positioning of the turn-around boring, become almost the only method in the machine tool

on the long hole boring. tool, and discusses the aspects of design, process scheme for the overall design,

component design. tool and boring spindle diagram. Key words: spindle box; combination machine; processing technology

|

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1