|

设计简介 |

设计描述:

文档包括:

word说明书一份,共36页,约10000字

任务书一份

开题报告一份

CAD版本图纸,共7张

摘 要

我国是一个农业大国,每年都会产出大量粮食,也需要大量的化肥等相关化工物品。所以如何将这些东西包装就显得尤为重要,为此也产生了一个市场——缝包机生产业。

缝包机是为塑料编织物的缝合的设备,主要完成编织物的拼接,封口等工作.工艺要点是缝合强度。.通用型号是GK. GK系列工业缝纫机按线迹分有单线链式和双线链式两种,按机针数分为单针和双针两种,按用法分为台式缝包机,手提式缝包机,立式缝包机.国产台式缝包机的主要型号是GK2和GK8系列的缝纫机;国产手提式缝包机主要是GK9系列,已经用了很多年了,另外现在国内有仿制日本和德国的手提缝包机;国产立式缝包机以GK35系列最为流行,为仿制德国产品。其优点及特点有:

1.降低劳动强度,改善劳动条件;

2.提高劳动生产率,增加生产效益;

3.提高包装质量,促进文明生产;

4.节约人力和物力,降低包装加工成本;

5.完成很多人工无法完成的包;

6.促进外贸发展,为国家多创外汇

关键词:运输机,自动,缝包机

ABSTRACT

Our country is a large agricultural nation, every year of grain output, will need a lot of chemical fertilizer and other related chemical items. So how to bring these packaging becomes especially important, therefore also produced a market - seam charter industries.

Packer is for plastic woven fabrics seam stitched equipment, mainly completes basketwork splicing, sealing etc. Process points is suture intensity. GK. General model is j GK series of industrial sewing machine press line mark single-lane chain and double points two, press machine chain stitch count is divided into single needle and double needle two kinds, press usage into desktop seam charter flights, portable seam charter flights, vertical joints. Domestic desktop seam charter the main model is GK2 charter GK8 series of sewing machines; and If GK9 FengBao homemade portable machine series, has been used for many years, also now domestic have copied Japan and Germany portable seam charter flights; Domestic vertical joints GK35 series on the most popular charter for generic Germany products. The advantages and features are:

1. Reduce the labor intensity, improve working conditions;

2. Improve labor productivity and increase production efficiency;

3. Improving packing quality, promote civilized production;

4. Save manpower and material resources, reduce the packaging processing cost;

5. Complete many artificially cannot complete bag;

6. Promote foreign trade development, more for the country and foreign exchange

Key words: Transporters, automatic, seam charter flights

目 录

1 绪论-------------------------------------------------------------------------------------------------------------------1

1.1设计方案及部件组成--------------------------------------------------------------1

2外购部分说明-----------------------------------------------------------------------------------------------------2

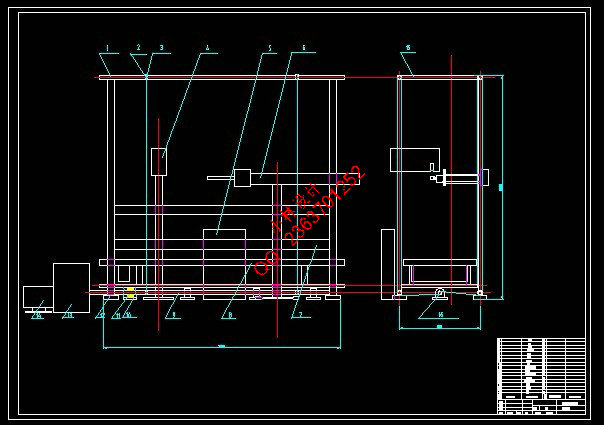

3运输带起吊部分及外部支架-----------------------------------------------------------------------------3

3.1起吊部分设计---------------------------------------------------------------------------------------------3

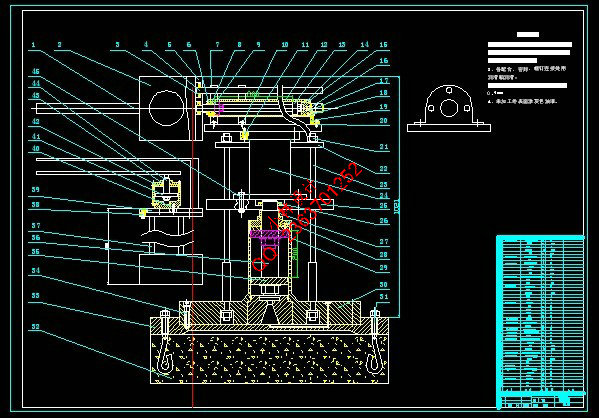

4机械手及夹持部分设计-----------------------------------------------------------------------------------19

4.1机械手的座标型式与自由度-------------------------------------------------------------------19

4.2 机械手的手部结构方案设计-----------------------------------------------------------------19

4.3机械手的手臂结构方案设计------------------------------------------------------------------19

4.4 机械手的驱动方案设计-------------------------------------------------------------------------19

4.5 机械手的控制方案设计-------------------------------------------------------------------------19

4.6机械手的主要参数-----------------------------------------------------------------------------------20

4.7机械手的技术参数列表---------------------------------------------------------------------------20

4.8气缸的直径-----------------------------------------------------------------------------------------------21

4.9缸筒壁厚的设计---------------------------------------------------------------------------------------23

4.10耗气量的计算-----------------------------------------------------------------------------------------23

4.11 气缸进排口的计算-------------------------------------------------------------------------------24

4.12气动系统设计-----------------------------------------------------------------------------------------24

5 PLC控制设计-----------------------------------------------------------------------------------------------------26

5.1 PLC的选择及工作过程----------------------------------------------------------------------------26

5.2 PLC的使用步骤--------------------------------------------------------------------------------------27

5.3机械手PLC控制方案------------------------------------------------------------------------------27

6参考文献-----------------------------------------------------------------------------------------------------------30

7致谢-------------------------------------------------------------------------------------------------------------------31

|