|

|

|

|

设计名称 |

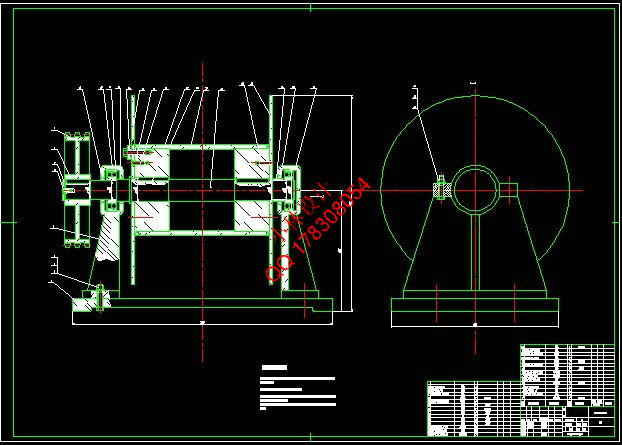

自动采油系统地面提升绞车设计 |

|

|

设计编号 |

V129 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

11000字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

2013.9.26 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

设计描述:

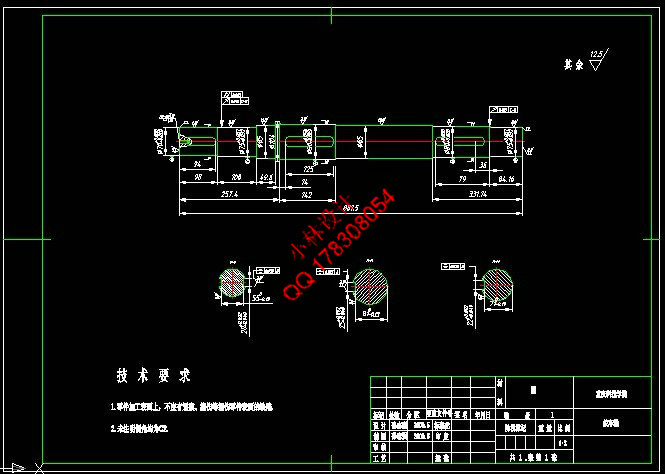

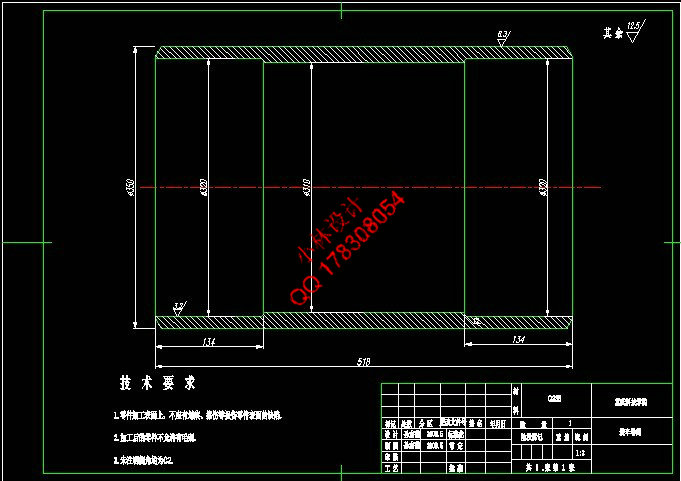

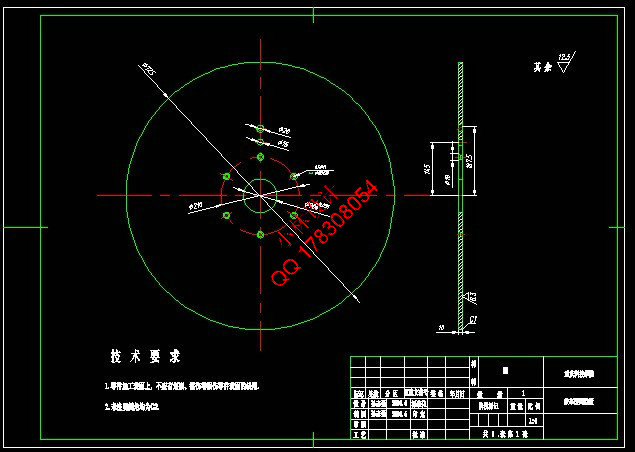

文档包括: CAD版本图纸,共5张

筑路和矿井提升等机械中的组成部件,因操作简单、绕绳量大、移置方便而广泛使用。在国内,平均每年需求

各种不同规格的绞车数万台,因此,改进质量,降低成本对绞车的开发具有重要意义。 作原理和操作工艺的基础上,在已知相关设计参数的前提下,从对绞车整体方案的确定、滚筒和滚筒轴等重要 零件的设计、绞车传动方案的确定,最后运用AutoCAD软件等绘图软件对其装配图和重要零件图的绘制,使得设 计成果更清晰更直观地表达出来。设计中,通过综合运用所学的知识,查阅相关资料和借鉴一些经验数据,确

保设计出的绞车能很好的满足采油工作,为钢丝绳柔性连续抽油杆技术的推广应用提供重要的保障。 Abstract Winch with a rope or chain winding drum or traction to enhance the small light weight lifting equipment, also known as the winch can be used alone, but also for lifting, road building and mine hoist machinery, such as the composition of components, due to operation simple rope around a large amount of displacement and the extensive use of convenience. In China, the average annual demand for a variety of different specifications of the winch of tens of thousands of units,

therefore, improve quality, reduce costs to the winch of great significance to the development. design is in the understanding of oil field fishing winch basic working principle and operation process on the basis of the known design parameters related to the premise, from the overall program to determine the winch, drum and drum shaft and other important parts of the design, winch drive program to determine the final use of AutoCAD software, graphics software, such as assembly drawings and mapping the important parts, making the results more clearly designed to express more directly. Design, through the integrated use of knowledge, access to relevant information and draw on some empirical data to ensure that the winch can be designed to meet a very good production work, flexible continuous sucker rod steel wire rope technologies provide

important protection.

目 录 |

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1