|

设计简介 |

设计描述:

文档包括:

WORD版设计说明书1份,共35页,约13000字左右

CAD版本图纸,共10张

摘 要

磁性分离技术是一门古老的技术,在200多年前就有磁性物质和非磁性物质分离的记载。在磨削加工中,随着加工精度的提高,高速磨削和强力磨削技术飞速发展,除了选择合理的磨削参数以外,还必须提高磨削液的循环质量。磁性分离器作为一种机床辅机,尚属于一种冷门产品。国内虽有许多厂家生产,但专业厂家并不多。磁性分离器对提高磨削液的循环质量有着非同一般的作用。磁性分离器能够有效去除冷却液中的铁质,无滤材消耗。方便安装,可与其他形式过滤机如鼓式(滚筒式)纸带过滤机、平网式纸带过滤机、真空负压式纸带过滤机等组合使用。

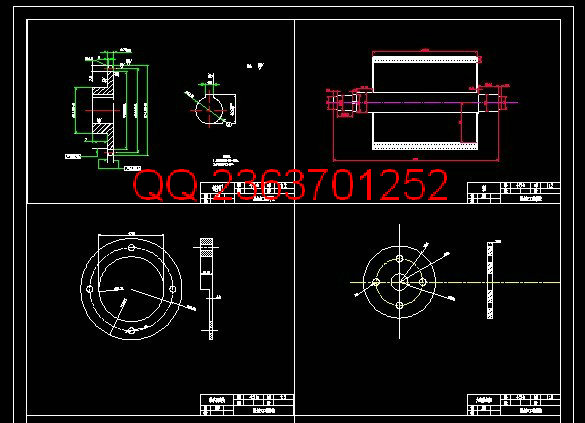

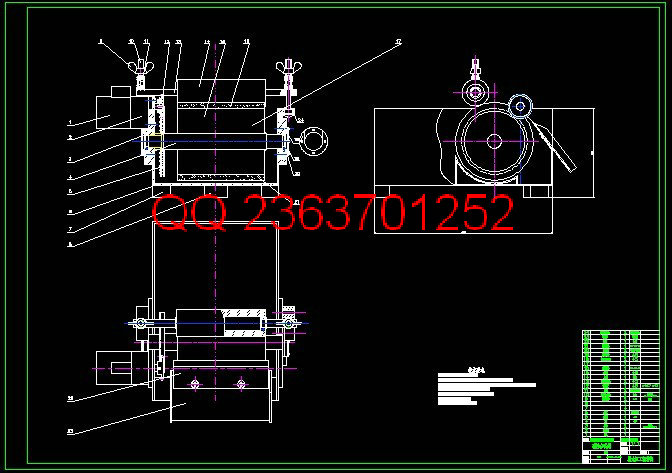

本课题来源于长春第一汽车制造有限公司。通过对市场上已有的磁性分离器的分析和计算,并对市场上产品优缺点进行了保留和改进,最终设计出一套符合客户使用要求的磨削液循环的净化装置。确定分离器的总体结构,机器由减速机、箱体、磁辊、胶辊等几部分组成。

关键词:磁性分离技术,分离器,胶辊式,磁性分离器

ABSTRACT

Magnetic separation technology is an old technology, 200 years ago have magnetic material and non-magnetic material separating the records. In the grinding process, along with the improvement of precision, high-speed grinding and grinding technology rapid development of strength, in addition to choose the right grinding parameters, it also must improve the quality of grinding fluid circulation. Magnetic separator, as a machine auxiliary, yet is a popular product. Although many domestic manufacturers, but not many professional manufacturers. Magnetic separator to improve the quality of the cycle of grinding fluid has unusual role. Magnetic separator can effectively remove the iron in the coolant, no filter consumption. Easy to install, as with other forms of filter drum (drum) tape filter, flat filter net-tape, vacuum-type filter such as tapes used in combination.

The main subject of customer and company requirements should be designed, already on the market through the magnetic separator the analysis and calculation, and the advantages and disadvantages of the product on the market to retain and improve the final design a line with the requirements of customers Cycle of grinding fluid purification device. Initially identified the overall structure of separator, the machine from the reducer, box, magnetic roller, roller several components. Its decomposition by modeling and then compare the assembly and then Yes to confirm the accuracy of its sheet metal and then, and two-dimensional drawings of the conversion, and finally put into its production.

KEY WORDS:magnetic separation technology,separator, rubber roller,magnetic separator

目录

摘要

Abstract

第一章 绪论

1.1磁性分离器技术简介

1.2国内外发展现状

1.3排屑机械的发展趋势

1.4研究该课题的意义

1.5研究问题的提出

第二章 总体方案设计

2.1磁性分离技术简析

2.2确定总体方案

2.3工作原理说明

2.4本章小结

第三章 方案细化设计

3.1确定电动机类型

3.2传动方式设计

3.3链传动设计计算

3.3.1链条选择

3.3.2链轮齿形

3.3.3链轮基本参数和主要尺寸

3.3.4链轮的结构

3.3.5链轮的材料和润滑方式

3.4轴的设计计算

3.4.1轴的材料选取

3.4.2轴的结构尺寸

3.4.3磁辊与轴的链接

3.5排屑装置材料选择

3.5.1刮板材料选择

3.5.2导屑槽材料选择

3.6弹性材料的选择

3.7轴承型号选择

3.8本章小结

第四章 检查与维护

结论

参考文献

致谢

|