|

设计简介 |

设计描述:

文档包括:

Word版说明书一份,共60页,约16000字

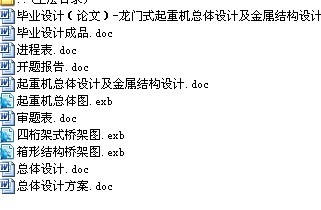

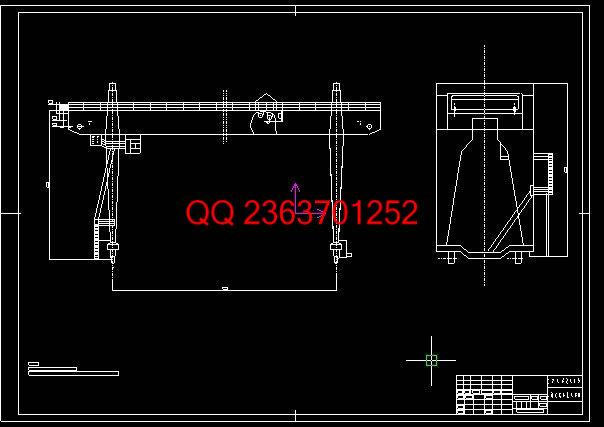

CAD版本图纸,共3张:

摘要:

改革开放以来,随着国民经济的高速发展,市场对起重机的需求量不断增长。近年来,起重机工业一直以15%左右的增长速度快速发展,起重机工业企业的所有制成分也发生了巨大变化,除了国有专业起重机厂外,集体、合资、独资和私营也得到了快速发展。

研究推广能提高劳动生产率及产品质量、降低成本和扩大起重机应用范围的各种领域工作,也是起重机技术的发展方向之一。目前国内外相继涌现了高性能工艺、适应工作环境能力、承载能力强功能、抗疲劳强度性能及抗弯曲性能性能等精制、高校、经济的起重机设计新方法。

虽然中国起重机工业在过去十多年中取得了令人瞩目的发展,但许多方面与工业发达国家相比仍有较大的差距。

目前,起重运输机金属结构主要构件所用的材料有普通碳素钢,优质碳素结构钢,普通低合金钢,合金结构钢。金属结构的支座常用铸钢。金属结构的联分为焊接和螺栓联接两大类。

关键词: 起重机,金属结构,承载能力,疲劳强度,碳素钢。

Summary :

Since the reform and opening up, with the rapid development of the national economy, the growing market demand for cranes. In recent years, the crane industry has been around for 15% growth rate, rapid development, the ownership of components crane industry has undergone tremendous changes, with the exception of state-owned professional crane plant, collective, joint ventures, investment and private development has been rapid.

Promote research to improve productivity and product quality, reduce costs and expand the scope of application of the various field cranes and crane technology development directions. Current and emerging high-performance succession process, the capacity to adapt to the working environment, supports a strong ability to function, to resist fatigue strength to resist bending performance and the performance of refined performance, colleges, and economic crane design new methods.

Although Chinese crane industry in the past 10 years has made remarkable progress, but with many industry lags far behind developed countries.

Currently, the major lift transport aircraft structural components used in the metal materials with ordinary carbon steel, quality carbon structural steel, low alloy steel ordinary, alloy structural steel. Common cast steel base metal structure. Metal welding and bolts into the structure of the links in two broad categories.

key wordS: Hoist crane, Metal structure

目录

前言………………………………………………………………………1

1起重机的概述………………………………………………………2

2龙门式起重机设计的总体设计……………………………………5

2.1龙门起重机总体设计所需的基本参数……………………………………5

2.2起重机的选型…………………………………………………6

2.2.1起重机基本型式的选择…………………………………………6

2.2.2起重机主要性能指标的选择………………………………………6

3 起重机金属结构设计………………………………………………7

3.1金属结构概述……………………………………………………7

3.2箱形结构门架强度计算……………………………………………8

3.2.1金属结构的基本参数选择与设计计算…………………………10

3.2.2 主减速器的润滑…………………………………………………16

3.3驱动桥-差速器……………………………………………………18

3.3.1对称式圆锥行星齿轮差速器的基本参数选择与设计计算……19

3.4 驱动桥-半轴………………………………………………………25

3.4.1全浮式半轴的设计计算与校核…………………………………25

3.5 驱动桥-桥壳………………………………………………………28

3.5.1 钢板冲夺焊接整体式桥壳的受力分析及强度计算……………29

4 总结…………………………………………………………………32

致谢……………………………………………………………………33

参考文献………………………………………………………………34

附录A…………………………………………………………………35

附录B…………………………………………………………………37

|