|

设计简介 |

设计描述:

文档包括:

Word版说明书一份,共35页,约11000字

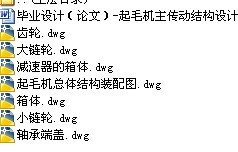

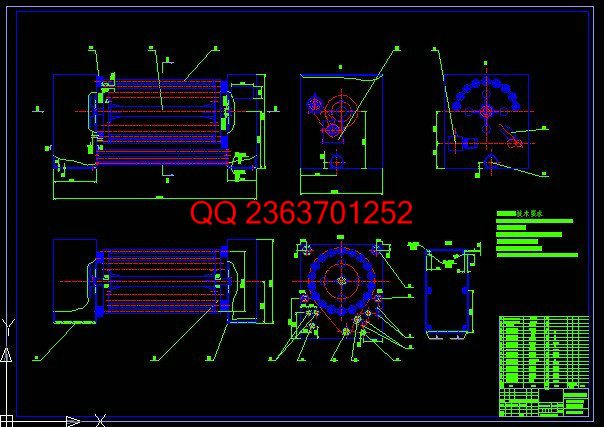

CAD版本图纸,共7张:

目 录

1 前言………………………………………………………………………………1

2概述……………………………………………………………………………2

2.1 课题的国内外现状………………………………………………………………2

2.2 研究的价值………………………………………………………………………2

2.2 研究的主要物化成果……………………………………………………………2

3总体方案论证…………………………………………………………………3

3.1 已知技术参数……………………………………………………………………3

3.2 结构方案的确定…………………………………………………………………3

4 主传动部分的设计……………………………………………………………4

4.1 设计总述…………………………………………………………………………4

4.2 电动机的选择……………………………………………………………………4

4.3皮带轮的设计……………………………………………………………………5

4.4链轮的设计…………………………………………………………………8

4.5减速器齿轮的设计…………………………………………………………………10

4.6减速器轴的设计……………………………………………………………………16

4.7减速器箱体的设计………………………………………………………………22

5 装配图与传动路线……………………………………………………………26

5.1装配图…………………………………………………………………………26

5.2传动路线………………………………………………………………………28

6 总结……………………………………………………………………………29

参考文献…………………………………………………………………………30

致谢………………………………………………………………………………31

附录…………………………………………………………………………………32

起毛机主传动结构设计

摘 要:本课题是在对国内外的起毛机广泛调研的基础上,对其结构、电气、传动等做了许多改进性设计。目前使用较广泛的国产M301起毛机由单台电机作拖动动力源,各传动部分由机械联接协同运行。该类起毛机工作稳定,维修简单,但产量低,改变工艺困难,难以获得高质量的起绒效果。

起毛机的主传动结构设计,尤其对其中的带传动与链传动做了详细地设计与校核。对主传动中的减速器做了创新性设计,达到了预期的目的,对起毛机的改进和发展做了一定的探索。本课题的传动部分,较传统的传动结构,做了一定的改进,就是改变了过去那种传动方式,通过采用行星轮系这种结构,很好的实现了较大的传动比。

通过本次设计,我对传动部分的全过程有了清醒而直观的认识,了解了起毛机的工作原理,对轴、链轮、带轮等主要零件的设计及精度的确定具备了一定的经验知识,能够正确地选取标准零件的结构及尺寸。由于知识及实践经验的缺乏,在设计过程中,尚存在许多不足之处,尤其是减速器的体积、效果等方面,有待以后的工作、学习中改进。

关键词:起毛机;结构设计;主传动设计;减速器设计

The Structure Design of Main Transmission of Teasing Machine

Abstract:The subject is on the basis of extensive investigation and research about teasing machine at home and abroad, during the design, the structure, electrical and transmission system has been improved. The current home-made teasing machine of M301 has been extensively used, and its dragging power is generated from the single electromotor, and the transmission system is operated by mechanical connections. This kind of teasing machine works staidly and maintains simply, but its shortages are low outputs, processes changed difficultly and gigging effect of high quality obtained impossibly.

The structure design of main transmission system of the teasing machine, especially belt drive and chain drive have been designed and checked in detail. The retarder of the main transmission system is done innovative design, which has achieved expected results and done some exploration for the improvement and development of the teasing machine. The transmission system has been improved in terms of previous transmission structure, which uses epicyclical train instead of the past structure in order to get high gear ratio.

Through the design of teasing machine, the overall processes of the transmission system have been clearly and directly known. Meanwhile, I acquaint with operating principle of teasing machine, the main parts of which such as axis, chain pulley and band pulley have been acquired lots of experience about their design and precision. Also I have learnt to select the structure and sizes of standard parts. However, because of lack of practical experience, I discover lots of deficiencies during the design of bulk and results of the retarder. Therefore, I will try to do better in the future in my work. words:teasing machine; structure design; main transmission design; retarder design

|