|

设计简介 |

设计描述:

文档包括:

Word版说明书一份,共78页,约17000字

外文翻译一份

CAD版本图纸,共7张:

摘要 II

Abstract III

第一章 绪论 1

1.1本课题研究意义 1

1.2 国内电牵引采煤机的技术特点及发展趋势 2

1.2.1 采煤机的技术特点 2

1.2.2 采煤机的发展趋势 3

1.3 总体方案的确定 4

1.3.1 采煤机类型 4

1.3.2 采煤机的组成 4

1.4截割部结构及技术特征 6

1.4.1截割部传动方式确定 6

1.4.2 电动机的选择 8

第二章 传动参数的确定 9

2.1总传动比的计算 9

2.2传动比的分配 9

2.3确定各轴的转速n、功率P、转矩T 10

第三章 齿轮啮合参数及强度计 11

3.1齿轮的初步设计及强度校核 11

3.1.1第一级减速齿轮传动设计计算及强度校核 12

3.1.2 第二级减速齿轮传动设计计算及强度校核 15

3.1.3 三级减速齿轮传动设计及计算 19

3.1.4 一级减速中惰轮轴的齿轮设计计算及校核 22

3.1.5 三级减速中惰轮轴的齿轮设计计算及校核 24

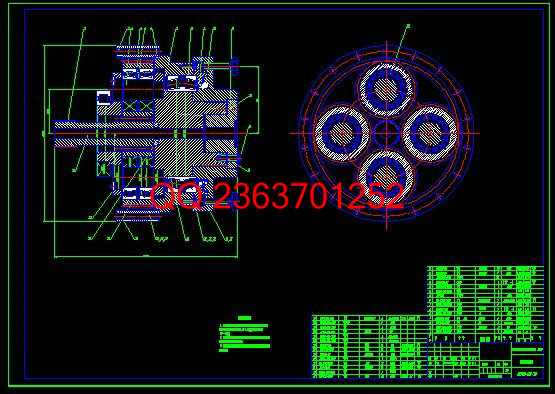

3.2 行星减速机构的齿轮设计计算及校核 26

第四章 轴及轴承的设计 31

4.1轴的结构设计及其强度校核 31

4.1.1 Ⅰ轴的结构设计及其强度校核 31

4.1.2 Ⅱ轴的结构设计及其强度校核 36

4.1.3 Ⅲ轴的结构设计及其强度校核 41

4.1.4 Ⅳ轴的结构设计及其强度校核 47

4.1.5 Ⅴ轴的结构设计及其强度校核 53

4.1.6 Ⅵ轴的结构设计及其强度校核 57

4.1.7 大齿轮轴的结构设计及其强度校核 58

4.2 轴承的选用及其校核 64

4.2.1 Ⅰ轴上轴承的选用及其校核 65

4.2.2 Ⅱ轴上轴承的选用及其校核 66

4.2.3 Ⅲ轴上轴承的选用及其校核 66

4.2.4 Ⅳ轴上轴承的选用及其校核 67

4.2.5 Ⅴ轴上轴承的选用及其校核 68

4.2.6 Ⅵ轴上轴承的选用及其校核 69

第五章 截割部的润滑及密封 69

结 论 72

参考文献 73

摘要

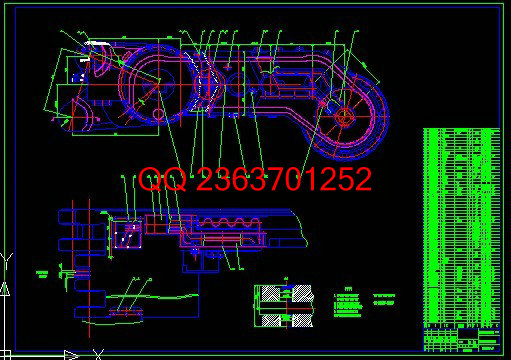

MG400/940-WD型采煤机是一种电牵引大功率采煤机,该机机身矮,装机功率大,所有电机横向布置,机械传动都是直齿传动,电机、行走箱驱动轮组件等均可从老塘侧抽出,故传动效率高,容易安装和维护。

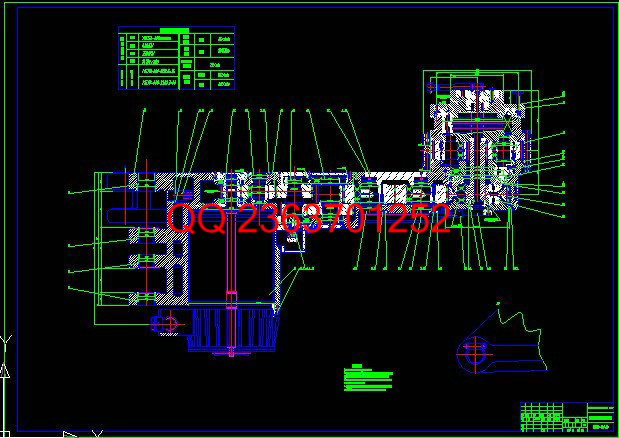

本说明书主要介绍了采煤机截割部的设计计算。MG400/940-WD 型采煤机截割部主要是由四级齿轮传动组成,截割部电机放在摇臂内横向布置,电动机输出的动力经由三级直齿圆柱齿轮和一级行星轮系的传动,最后驱动滚筒旋转。截割部采用四行星单浮动结构,减小了结构尺寸,采用大角度弯摇臂设计,加大了过煤空间,提高了装煤效果。

在设计过程中,对截割部的轴、传动齿轮、轴承和联接用的花键等部件进行了设计计算、强度校核和选用。本说明书主要针对主要部件的设计计算和强度校核进行了叙述和介绍。

此外,还对MG400/940-WD采煤机的使用与维护进行了说明,以便能更好的发挥该采煤机的性能,达到最佳工作效果。

关键词:采煤机;截割部;行星轮系;齿轮传动设计

Abstract

The MG400/940-WD type mining machine is that a kind of electricity draws the high-power mining machine, this machine fuselage is low, Installation is large in power, all electrical machineries are fixed up horizontally, mechanical drive is all the transmission of straight tooth, electrical machinery, walk case drive wheel package etc. can take from old pool side out, so the transmission is high in efficiency, easy to install and safeguard.

Calculate in design which cuts the cutting department of main introduction mining machine of this manual. It is made up of a moderate breeze gear wheel transmission that the MG400/940-WD type mining machine cuts the cutting department, cut the electrical machinery of cutting department and put to fix up horizontally in the rocker arm, the power that the motor outputs leans on a round of transmission of department of gear wheel and planet round via the tertiary straight tooth, urge the cylinder to rotate finally. Cut the cutting department and adopt the floating structure of four planetary forms, have reduced the physical dimension, adopt the large angle to curve the rocker arm to design, have strengthened the space of coal, have improved the coal result of putting.

In the course of designing, to cutting the axle of the cutting department, gear wheel of the transmission, parts such as the bearing and spline linking using, etc have designed to calculate, the intensity is checked and selected for use. This manual mainly designs for main part one calculating to check with the intensity have narrated and introduced.

In addition,returning use for MG400/940-WD mining machine and maintenance proves, In order to be able to good full play performance of person who should mine, reach the best working result.

Keyword: Mining machine ;the cutting department ; A department of planet ;Gear wheel of the transmission Design

|