|

设计描述:

文档包括:

WORD版设计说明书1份,共32页,约16000字

开题报告一份

任务书一份

文献综述一份

外文翻译一份

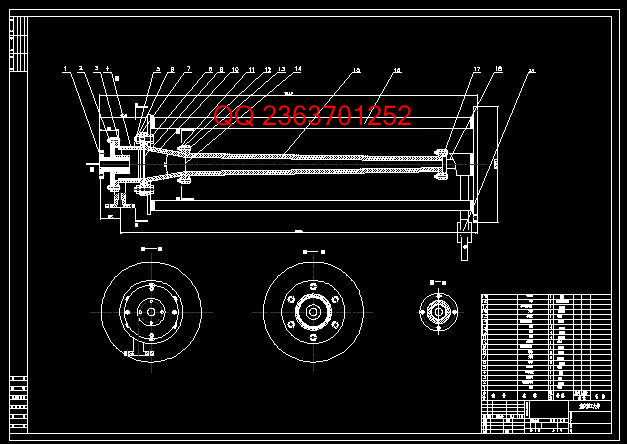

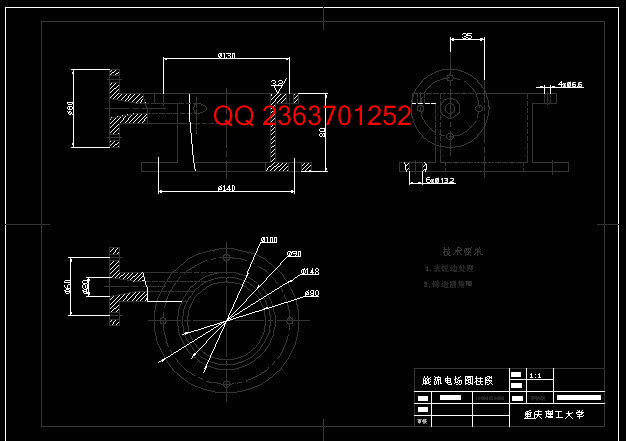

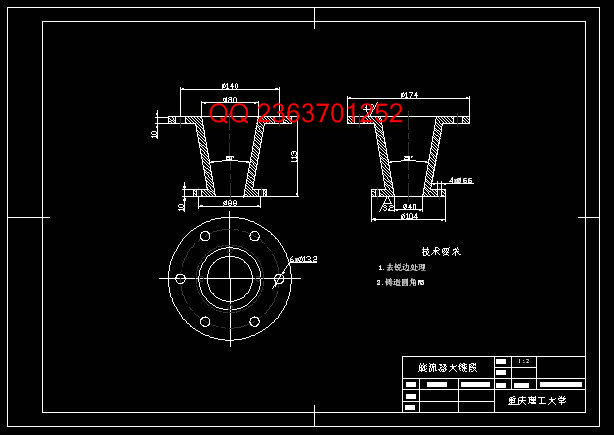

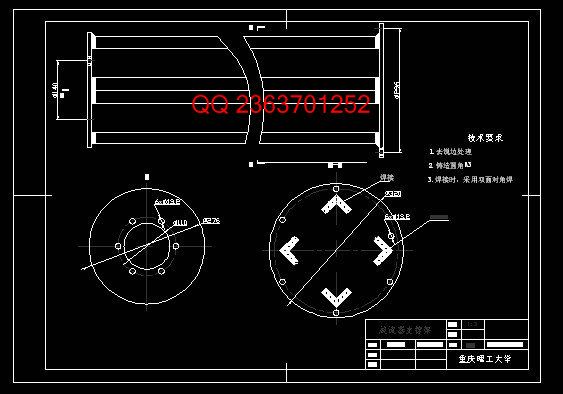

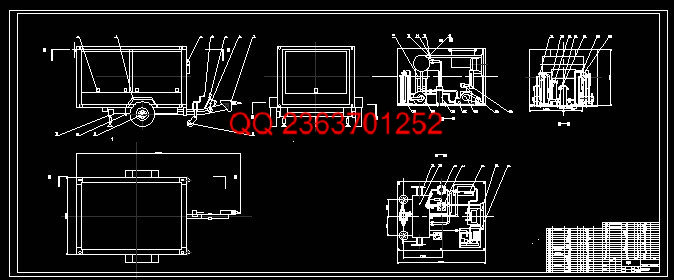

CAD版本图纸,共12张

目 录

摘 要 ……………………………………………………………………………Ⅰ

Abstract…………………………………………………………………………Ⅱ

1 绪论………………………………………………………………………………1

2 润滑油多场联合净化装备总体设计……………………………………………2

2.1一级旋流器的设计……………………………………………………………3

2.1.1旋流器的分类……………………………………………………………3

2.1.2水力旋流器及其工作过程……………………………………………4

2.1.3.水力旋流器的分类、分离原理及其发展概况………………………4

2.1.4.水力旋流器的应用概况………………………………………………4

2.1.4.1 水力旋流器在煤炭工业中的应用…………………………………5

2.1.4.2水力旋流器在选矿工业中的应用…………………………………5

2.1.4.3水力旋流器在食品工业中的应用…………………………………6

2.1.4.3水力旋流器在污水处理中的应用…………………………………6

2.1.4.4水力旋流器在造纸中的应用………………………………………7

2.1.4.5水力旋流器在石油业中的应用……………………………………8

2.1.5 水力旋流器选型………………………………………………………9

2.1.6 常见液—液分离水力旋流器的结构………………………………10

2.1.7 水力旋流器机构设计及参数设计……………………………………11

2.1.7.1 大小锥角的选择……………………………………………………12

2.1.7.2 主体直径D确定……………………………………………………12

2.2.7.3尾管长度的选择……………………………………………………12

2.1.7.4 入口设计…………………………………………………………12

2.1.7.4 旋流器的端盖……………………………………………………13

2.1.8旋流器的安装…………………………………………………………13

2.2 旋流电场的设计……………………………………………………………14

2.2.1 旋流电场的简介…………………………………………………… 14

2.2.2 旋流电场的工作原理………………………………………………14

2.2.3 电场的选择……………………………………………………………15

2.2.4 电极的分布情况…………………………………………………15

2.2.5 旋流电场………………………………………………………………16

2.3真空单元………………………………………………………………16

2.4真空单元元件元件的选用…………………………………………………17

2.5 管路设计及装配…………………………………………………………18

3 总结……………………………………………………………………………20

致谢…………………………………………………………………………………21

参考文献……………………………………………………………………………22

文献综述…………………………………………………………………………24

摘要

随着世界经济的不断高速发展,机械、电力、运输和化工等基础工业也在不断发生着日新月异的变化。作为工业日常生产过程中机械设备运转必备品,且有润滑作用的润滑油来说,它的需求量也越来越大。润滑油是从石油中提炼出来的,是工业生产过程中不可或缺的一种石油产品,也是一种不可再生资源,而且润滑油的加工成本比较高,因此它的再利用是很有必要的,这样做既环保又节能。水是使润滑油液受到污染的常见外来污染物,因而润滑油脱水净化也是润滑油液二次利用的必备途径。

目前油液脱水的主要方法是真空加热法,本文的主要内容是润滑油多场联合净化装备设计,所谓润滑油多场联合净化装备就是利用旋流场、电场和重力场等来对润滑油中的水和其他影响润滑油使用性能的杂质进行处理的一种特种设备。由于真空加热脱水单元已经设计完毕,本次主要做的主要是是第一级旋流器和旋流电场的设计以及管路设计。

关键词:液—液分离旋流器;电场;加热真空脱水;油水分离;润滑油

Abstract

As the world economy high speed development, machinery, electricity, transport, and chemical and other basic industries are changing with each passing day change, so that the demand of the lubricating oil as the industrial daily production necessary lubrication of mechanical equipment in the process of operation is becoming more and more big. For the reasons that the lubricating oil is oil refining, it is a kind of oil which is indispensable in the process of industrial production products and processing the lubricating oil is very high .So it is very necessary to recycle the lubricating oil .Water is the lubrication oil pollution in the common foreign pollutants so that lubricating oil dehydration purification is also an essential way to lubricating oil secondary use.

This article tells the lubricating oil field joint purification equipment design, so-called lubricating oil field joint purification equipment is a kind of special equipment that using spiral flow field and electric field and gravity field to get the water and other impurities affect the functional performance of the lubricating oil out .This equipment is designed on the basis of a variety of technologies such as conceptual design, dehydration purification principle is in a market segment for liquid-liquid hydro cyclone separation hydro cyclone technology, pulsed electric field technology and vacuum heating dehydration technology which has been used .

Key words: Liquid - liquid separation and cyclone, the electric field, vacuum heating dehydration, separation of water from oil, Lubricating oil

|