|

设计简介 |

设计描述:

文档包括:

pdf版设计说明书1份,共41页

外文翻译一份

开题报告一份

任务书一份

CAD版本图纸,共12张

SW三维图 一份

目录

摘要........................................................................................................ 1

Abstract................................................................................................ 2

1 绪论............................................................................................. 3

1.1 变速器结构与工作原理的分析........................................................... 3

1.2 汽车变速器性能试验台发展状况........................................................ 4

1.3 本课题的目的和主要研究内容.......................................................... 4

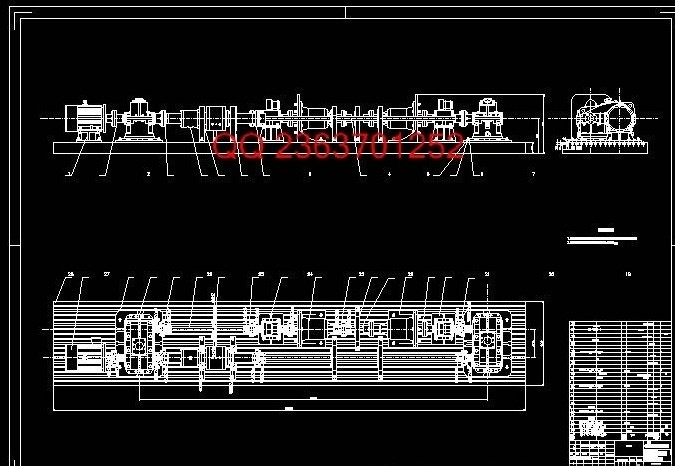

2 总体方案论证.............................................................................................. 5

2.1 试验台布置方案的选择........................................................................ 6

2.2 加载装置的选择...................................................................................... 7

2.2.1 电液比例加载系统................................................................. 7

2.2.2 液压加载器................................................................................ 8

3 总体技术方案设计...................................................................................... 9

3.1 电机的选择....................................................................................... 9

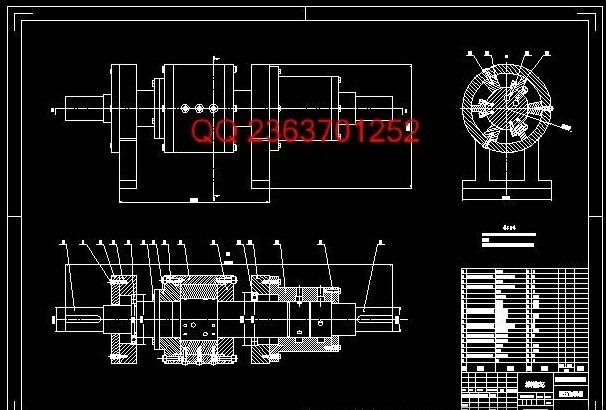

3.2 变速箱的设计............................................................................. 9

3.2.1 确定变速箱的主要参数................................................................. 9

3.2.2 齿轮的设计计算及校核.................................................................. 9

3.2.3 轴的设计计算及校核............................................................... 14

3.2.4 键的设计计算及校核...................................................................... 17

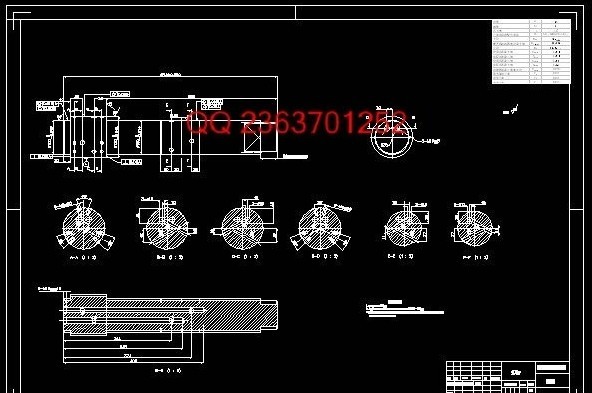

3.3 加载器的选择..................................................................... 18

3.3.1 心轴的设计.................................................................................. 18

3.3.2 内叶片设计.................................................................................. 19

3.3.3 外叶片设计.................................................................................... 20

3.3.4 液压缸的设计.................................................................................. 21

3.3.5 摆缸缸盖的设计............................................................................... 23

3.3.6 聚流体的设计.............................................................................. 24

3.4 传感器的选择.................................................................................... 25

3.5 联轴器的选择..................................................................................... 26

4 试验及数据处理方法........................................................................ 27

5 SolidWorks 软件简介与建模过程........................................................ 28

5.1 SolidWorks 软件简介.......................................................................... 28

5.2 Solidwoks 建模................................................................................ 28

5.2.1 传动箱建模................................................................................... 29

5.2.2 加载装置建模....................................................................... 31

5.2.3 总装建模..................................................................................... 33

6 结束语........................................................................................................... 35

致谢............................................................................................................... 36

参考文献............................................................................................ 37

摘要

汽车变速器,是一套用于来协调发动机的转速和车轮的实际行驶速度的变速装置,用

于发挥发动机的最佳性能。变速器可以在汽车行驶过程中,在发动机和车轮之间产生不同

的变速比,通过换挡可以使发动机工作在其最佳的动力性能状态下。

汽车变速器性能试验台是对汽车变速器进行综合性能测试的实验设备。通过试验

来检验汽车变速器设计的合理性以及评定变速器的综合机械性能。

本论文目的在于阐述我的毕业设计内容-汽车变速器性能试验台设计。试验台选用电

封闭试验台。本文主要由五个部分组成。分别是:绪论,总体方案设计,方案论证(计算),

微机控制系统设计,Solidworks 建模过程。其中方案设计和Solidworks 建模是耗时较多,

比较重点的部分。后面会详细介绍。

关键词:汽车变速器;试验台;Solidworks;微机控制

Abstract

The auto transmission is a device used to coordinate engine speed and the actual speed of the

wheel speed, used to play the best performance of the engine. Different variable speed

transmission in the car driving the process, between the engine and wheels, shift can make the

engine work in the best dynamic performance status.

The vehicle transmission assembly performance test bed vehicle transmission performance

testing of laboratory equipment. Test to test the rationality of the design of automotive

transmission and assessment of mechanical properties of the transmission.

The purpose of this paper is to elaborate on my graduation project content - automotive

transmission assembly performance test rig design. The test rig selection of electric closed test

bed. In this paper consists of five parts. They are: the introduction, the overall program design,

argument (computing), the microcomputer control system design, Solidworks modeling process.

Design and Solidworks modeling is time-consuming, compare the part of the focus. Later in

detail.

Key words: automotive transmission ;testing bed ;Solidworks ;control with microcomputer

|