|

设计描述:

文档包括:

Word版设计说明书1份,共28页,约12000字

任务书一份

PPT答辩一份

外文翻译一份

调研报告一份

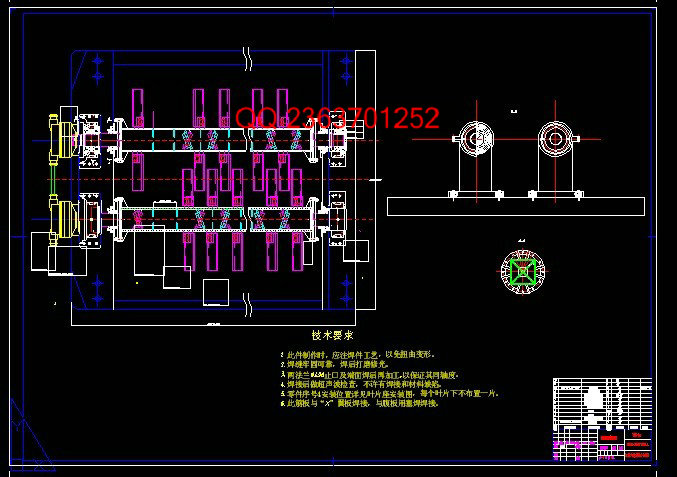

CAD版本图纸,共9张

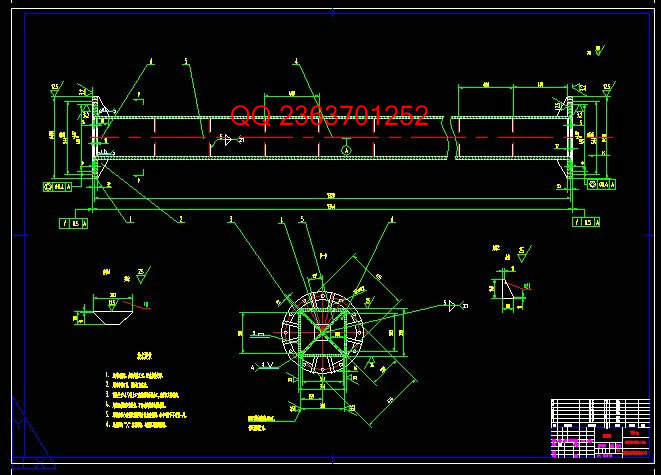

混煤机结构优化设计

专业班级:机械0903 学生姓名:

指导老师: 职称:讲师

摘要: 宁钢五丰塘焦化厂供煤系统配置两台900t/h 双轴叶片式混煤机,自投入运行后,该混煤机多次发生断轴、端轴开裂等事故,造成生产中断,严重影响生产。本文通过对混煤机基本情况的了解和对混煤机结构的分析考察,采取了改变端轴连接结构,改变主轴端面结构提高主轴的强度和刚度等措施,从而改进混煤机设计缺陷。花键轴及相连减速机的零部件发生损坏的故障,通过对整体结构的分析,我们认为主要就是要增大主轴及其与端轴的整体刚度,保证端轴传递扭矩的具有足够的强度,消除端轴的径向摆动,让端轴只传递扭矩,保证减速机、端轴、及主轴尽可能轴线对中;本文设计的亮点就是在减速机与端轴之间增设联轴器,通过联轴器修正吸收来自负载的径向摆动。

关键词:混煤机 主轴断裂 结构连接 优化设计

Abstract

Ningbo iron and steel plant has two 900t/h double-shaft blade type coal mixer of the coal supply system .since put into operation, the mixed coal machine, multiple shaft broken end shaft cracking accident, causing production disruptions and the serious influence production. Based on the basic situation of coal mixing machine understanding and analysis of the coal mixer structure inspection, to change the link structure of axle end, change the spindle end structure improve the strength and stiffness of such measures, in order to improve the design of mixed coal machine defects. Spline shaft and connected reducer parts damaged fault, through the analysis of the whole structure, we think the key is to increase the spindle and shaft stiffness, securing sufficient strength of the shaft torque transmission, eliminate the radial swing axle end, that end shaft only transmitting torque, speed reducer, ensure the end axis, and the axis of spindle as possible.The bright spot is the coupling between the reducer and shaft, through the coupling correction absorption radial swing from the load.

Key words: Mixed coal machine Shaft fracture structural connection optimum design

目 录

前言???????????????????????????????????????????????????????????????2

Abstract??????????????????????????????????????????????????????????3

第1章混煤机基本介绍????????????????????????????????????????????6

1.1混煤机用途????????????????????????????????????????????????????6

1.2 操作环境??????????????????????????????????????????????????????6

1.3规范、标准和控制偏差??????????????????????????????????????????6

1.3.1本机设计标准和规范??????????????????????????????????????????6

1.3.2 本机技术性能参数控制偏差????????????????????????????????????7

1.4混煤机基本原理????????????????????????????????????????????????7

1.5混煤机基本参数????????????????????????????????????????????????8

1.6混煤机主要设备特点????????????????????????????????????????????8

1.7关键材质表???????????????????????????????????????????????????11

1.8数据检验大纲?????????????????????????????????????????????????11

1.9控制系统?????????????????????????????????????????????????????11

第2章混煤机出现的故障??????????????????????????????????????????12

第3章混煤机主轴故障原因分析及改进????????????????????????????14

3.1主轴强度复核?????????????????????????????????????????????????14

3.1.1主轴设计端面几何及力学分析?????????????????????????????????14

3.1.2 单根主轴的传递功率????????????????????????????????????????14

3.1.3 主轴传递的扭矩????????????????????????????????????????????15

3.1.4 主轴危险端面受力??????????????????????????????????????????15

3.2主轴的强度计算???????????????????????????????????????????????16

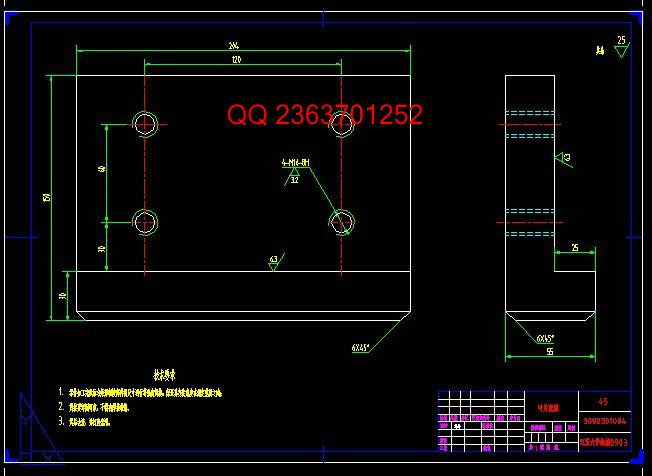

3.3主轴与端轴连结设计分析???????????????????????????????????????17

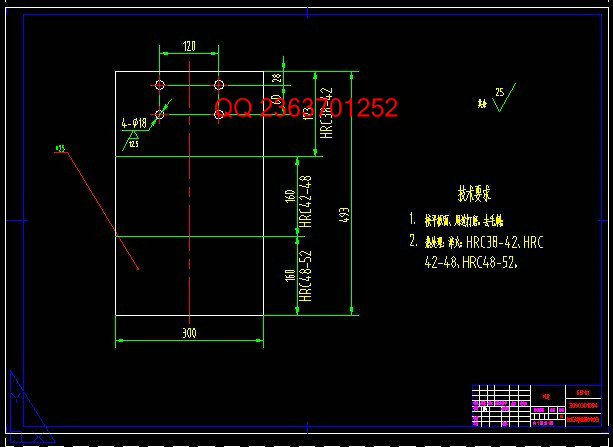

3.4主轴的结构改进设计??????????????????????17

3.4.1主轴断面改进????????????????????????17

3.4.2提高主轴刚度????????????????????????18

3.5具体改进措施?????????????????????????19

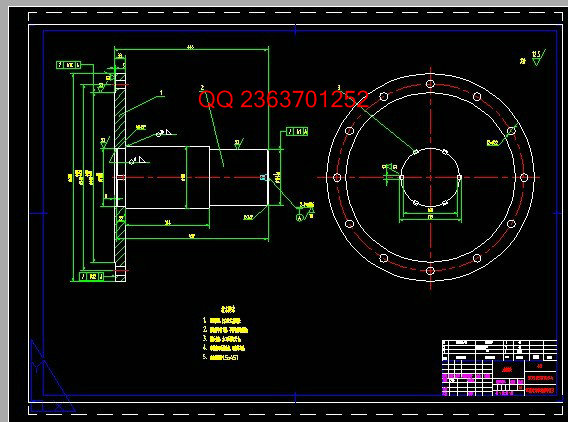

第4章.花键轴扭转疲劳断裂分析及改进??????????????21

4.1花键轴断裂状况????????????????????????21

4.2花键齿失效形式 ????????????????????????21

4.3花键齿扭转断裂分析??????????????????????22

4.3.1扭转疲劳断裂原因猜想????????????????????21

4.3.2扭转疲劳断裂结论性分析???????????????????23

4.4具体改进措施 ?????????????????????????23

4.5小结?????????????????????????????24

结 论???????????????????????????????26

致 谢???????????????????????????????27

参考文献?????????????????????????????28

|