|

设计简介 |

设计描述:

文档包括:

Word版设计说明书1份,共40页,约17800字

文献综述一份

任务书一份

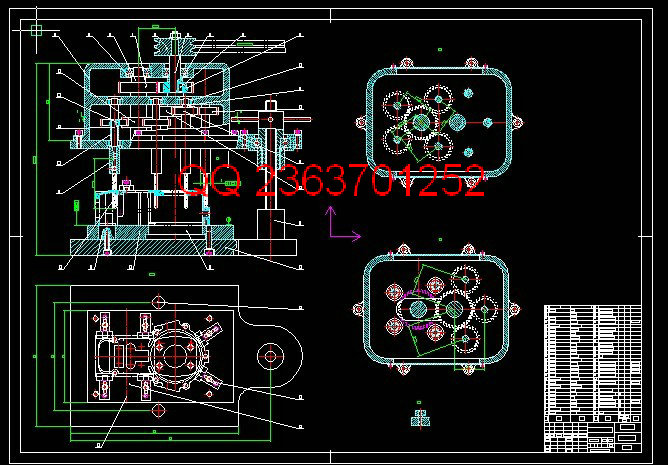

CAD版本图纸,共6张

目 录

第一章 引言 1

1.1论文背景及研究意义 1

1.2组合机床发展概况 1

1.2.1组合机床的由来 1

1.2.2组合机床技术装备现状与发展趋势 1

1.3本文研究的主要内容 2

第二章 组合钻床总体设计 4

2.1组合钻床工艺方案的制定 4

2.2 7孔组合钻床配置型式及结构方案的确定 4

2.3主要参数的计算 5

2.3.1确定切削用量,计算各主轴转速 5

2.3.2确定切削力F、切削转矩M、切削功率P 6

2.4组合机床总体设计 6

2.4.1被加工零件工序图 7

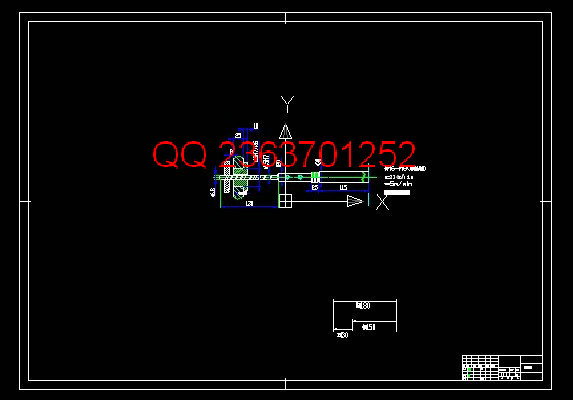

2.4.2加工示意图的设计 71

2.4.3机床联系尺寸图的绘制 11

2.4.4生产率计算卡 14

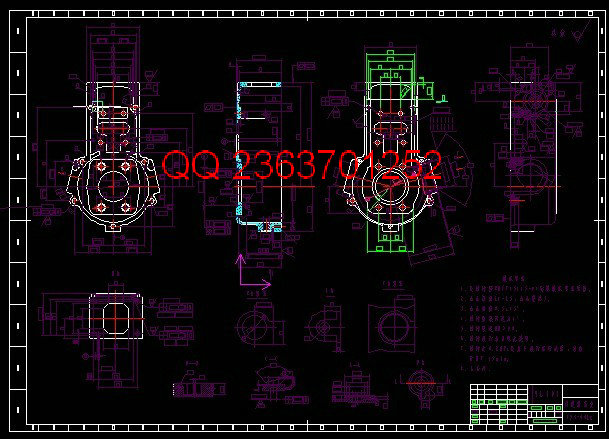

第三章 主轴箱设计 16

3.1绘制主轴箱设计原始依据图 16

3.2 主轴结构形式的选择及动力计算 17

3.3传动系统的设计和计算 18

3.4多轴箱的坐标计算 21

3.5主轴箱通用轴类零件选择 24

3.6 主轴及通用传动轴结构形式的选择方案 26

3.7 通用齿轮及其他通用件及传动轴轴承型号的选用 26

第四章 夹具设计 27

4.1 机床夹具的概述 27

4.2定位支承系统设计 27

4.2.1定位支承系统的设计原则 27

4.2.2定位支承元件及其布置 28

4.3导向装置设计 28

4.3.1导向装置的作用 28

4.3.2固定式导套的设计 28

4.3.3固定钻模板结构设计 29

4.4夹紧机构设计 30

4.4.1夹紧方案的确定 30

结论 32

致谢 33

参考文献 34

调速器前壳7孔组合钻床设计

专业班级:J机械0902 学生姓名:

指导老师: 职称:讲师

摘要 当前世界NC机床的研究现状

世界各国对数控机床、加工中心以至FMS、CIMS等各种新技术的研究与发展进程,是与世界经济形势紧密相连的。机床工业有世界经济相互促进和发展,进入21世界知识机警时代,人们的知识所起的作用更加突出,而机床工业作为机器制造业的基础,其重点地位与战略意义也更加明显。在1991—1994年间,世界经济衰退,昂贵的FMS,CIMS降温,1995—2000年间,世界经济在低速增长,根据当前世界市场各方面用户为提高生产率对NC机床的要求以及世界四大国际机床展(欧洲的EMO、美国的IMTS、日本的JIMTOF、中国的CIMT)上展品的分析,当前世界NC机床的技术研究主要有以下几点:

(1)、更加重视新技术和创新

在世界范围内,对新工艺、新材料、新结构、新单元、新元件的研究开发工作正在大力开展,如新的刀具材料、新的主轴结构、高速电主轴、高速直线电机等的开发研究。以加工工艺的改进创新为基础,为加工超硬、难切削材料及特殊复合材料及复杂零件、不规则曲面等在不断研究开发新机种。

(2)、提高机床加工的精度和研究

为了提高加工中心的加工精度,不断提高机床的刚度、减少振动,消除热变形,降低噪声,提高NC机床的定位精度、重复精度、工作可靠性、稳定性、精度保持性,世界很多国家都在进行机床热误差、机床运动及负载变形误差的软件补偿技术研究,并采取精度补偿、软件补偿等措施加以改善,有的已经可以使此类误差消除60%。并在不断开发精细加工,纳米加工。

(3)、提高机床加工生产率的研究

世界NC机床、加工中心及相应的高速点主轴、直线电机、测量系统、NC系统的开发,均以提高生产率为前提。

(4)、许多国家都已经开始对数控系统的智能化、开放化、网络化研究,数控系统的智能化的研究

主要表现在:为追求加工效率和加工质量的智能化,对加工过程的自适应控制,工艺参数自动生成进行研究;为提高驱动性能及使用连接方便的智能化,对反馈控制、电机参数的自适应运算、自动识别负载自动选定模型、自整定等进行研究;还有智能化的自动编程、智能化的人机界面、智能诊断、智能监控等方面的研究。

关键词: NC机床 主轴 夹具设计 定位

Research current situation of NC lathe in our times

Research and development process to such various kinds of new technologies as numerical control lathe , machining center , FMS , CIMS ,etc. of countries all over the world, linked to with the international economic situation closely. The machine tool industry has international economy to mutually promote and develop, enter 21 alert eras of World Affairs, the function that people's knowledge plays is more outstanding , and the machine tool industry is regarded as the foundation of the manufacturing industry of the machine, its key position and strategic meaning are more obvious. Within 1991-1994 years, the economic recession of the world, expensive FMS, CIMS lowers the temperature, among 1995-2000 years, the international economy increases at a low speed, according to requisition for NC lathe and the world four major international lathes exhibition in order to boost productivity of users of various fields of present world market (EMO , IMTS , JIMTOF , China CIMT of Japan of U.S.A. of Europe), have the analysis of the exhibit, there are the following several points mainly in the technical research of NC lathe in our times:

(1)、Pay more attention to new technology and innovation

Worldwide , are launching the new craft , new material , new structure , new unit , research and development of the new component in a more cost-effective manner, developmental research of for instance new cutter material , the new electric main shaft of main shaft structure , high speed , high-speed straight line electrical machinery ,etc.. Regard innovating in improvement of the processing technology as the foundation, for process ultra and hard difficult to cut material and special composite and complicated part , irregular curved surface ,etc. research and develop new lathe variety constantly.

(2)、Improve the precision and research of machine tooling

In order to improve the machining accuracy of the machining center , are improving rigidity of the lathe , reduction vibration constantly, dispel hotly and out of shape, reduce the noise , improve the precision of localization of NC lathe , repeat precision , working dependability , stability , precision keeping, world a lot of country carry on lathe hot error , lathe sport and load out of shape software of error compensate technical research, take precision compensate , software compensate measure improve , some may make this kind of error dispel 60% already. And is developing retrofit constantly, nanometer is being processed.

(3)、Improve the research of the machine tooling productivity

World NC lathe, machining center and corresponding some development of main shaft , electrical machinery of straight line , measuring system , NC system of high speed, under the prerequisite of boosting productivity.

(4)、elligent research of the numerical control system

Mainly showing in the following aspects: It is intelligent in order to pursue the efficiency of processing and process quality, the self-adaptation to the processing course is controlled, the craft parameter produces research automatically; Join the convenient one in order to improve the performance of urging and use intelligently, to the feedback control , adaptive operation , discerning automatically load selects models automatically , since carries on research whole definitely ,etc. of the electrical machinery parameter; There are such research of the respect as intelligent automatic programming , intelligent man-machine interface , intelligence diagnosing , intelligent monitoring ,etc..

Key Words:situation of NC,Spindle,Spindle box ,Location

|