|

设计简介 |

设计描述:

文档包括:

Word版设计说明书1份,共29页,约10000字

任务书一份

开题报告一份

PPT答辩一份

CAD版本图纸,共4张

数控车床自动回转刀架的设计

摘要

传统的普通车床换刀的速度慢、精度不高,生产效率低,不能适应现代化生产的需要。然而企业要在激烈的市场竞争中获得生存,它必须在最短的时间内以优异的质量、低廉的成本,制造出合乎市场需要的、性能合适的产品,于是对普通机床的换刀装置进行改进,成为了一条有效的捷径,使装置具有自动松开、转位、精密定位等功能。

本文通过对回转刀具的研究,全面对四工位立式回转刀架的主结构以及其传动结构进行研究与分析,并详细叙述了该机构的结构和发展,并且通过计算机对机构进行了设计。设计的数控換刀装置功能更强,换刀装置通过刀具快速自动定位,可以提高数控车床的效率,缩短加工时间;同时其可靠性更稳定,结抅简单。

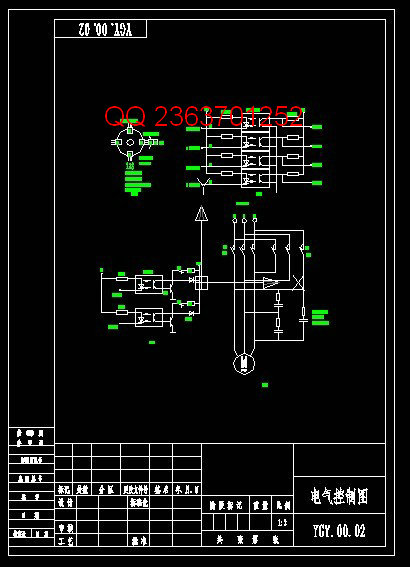

关键词: 自动回转刀架;换刀装置;机电系统;电气控制

CNC LATHES AUTOMATIC TURRET DESIGN

ABSTRACT

The traditional lathe cutter changing speed, high precision, low production efficiency, can not adapt to the needs of modern production.However the enterprise in the fierce competition in the market to survive, it must be in the shortest time with excellent quality, low cost, manufacturing out of the needs of the market, property right product, so the common machine tool device is modified, became an effective shortcut, so that the device has automatic loosen, transposition, precise positioning function.

This article through to the rotary tool of research, comprehensive four location circumrotating vertical turret main structure and its drive structure of research and analysis, and a detailed description of the structure and development, and the body was designed by computer.Design of the numerical control cutter changing device function is stronger, tool changing device through fast cutter automatic positioning, can improve the efficiency of NC lathe, the processing time is shortened; at the same time, its reliability is more stable, simple knot ju.

Key word:Automatic rotary knife; knife changing device; electrical system; electrical control

目 录

1 绪论...................................................1

1.1概述..................................................1

1.2数控车床自动回转刀架的概述............................1

1.3数控车床自动回转刀架的发展趋势........................2

1.4研究社会实际意义及应用效果............................3

1.5刀架的设计准则........................................3

1.6本文的主要研究内容....................................3

2 自动回转刀架的工作原理.................................5

3 总体结构的设计.........................................7

3.1减速传动机构的设计....................................7

3.2 上刀体锁紧与精定位机构的设计......................... 7

3.3 刀架抬起机构的设计................................... 7

4 数控车床自动回转刀架设计...............................9

4.1 蜗杆副的设计计算..................................... 9

4.1.1蜗杆的选型....................................................9

4.1.2蜗杆副的材料..................................................9

4.1.3按齿面接触疲劳强度进行设计....................................9

4.1.4蜗杆和蜗轮主要几何尺寸计算...................................11

4.2 蜗杆轴的设计........................................ 13

4.2.1 蜗杆轴的材料选择,确定许用应力...............................13

4.2.2 按扭转强度初步估算轴的最小直径.............................. 13

4.2.3确定各轴段的直径和长度.......................................13

4.2.4蜗杆轴的校核.................................................14

4.2.5键的选取与校核...............................................18

4.3 蜗轮轴的设计........................................ 19

4.3.1 蜗轮轴材料的选择,确定需用应力...............................19

4.3.2 按扭转强度,初步估计轴的最小直径.............................19

4.3.3确定各轴段的直径和长度.......................................19

4.4 中心轴的设计........................................ 20

4.4.1 中心轴的材料选择,确定许用应力............................... 20

4.4.2 确定各轴段的直径和长度...................................... 20

4.4.3轴的校核.....................................................21

4.5 齿盘的设计.......................................... 20

4.5.1 齿盘的材料选择和精度等级.................................... 21

4.5.2 确定齿盘参数................................................ 21

4.5.3 按接触疲劳强度进行计算...................................... 22

4.5.4按齿根抗弯强度设计...........................................22

4.6轴承的选用.......................................... 23

4.6.1 轴承的类型.................................................. 23

4.6.2 轴承的游隙及轴上零件的调配.................................. 23

4.6.3滚动轴承的配合...............................................23

4.6.4滚动轴承的润滑...............................................23

4.6.5滚动轴承的密封装置...........................................24

5 刀架体的设计..........................................25

6 回转刀架故障分析及排隙................................26

6.1刀架不能启动.........................................26

6.6.1 机械方面的原因............................................. 26

6.6.2 电器方面的原因..............................................26

6.2刀架连续运转、到位不停...............................26

6.3刀架越位过冲或转不到位 ..............................27

6.4刀架不能正常夹紧 ....................................27

6.5其它故障现象.........................................27

7 结论..................................................29

|