|

设计简介 |

设计描述:

文档包括:

设计word版本说明书一份,共37页,约15000字

CAD版本图纸,共9张

摘要

本设计目的就是设计一台可以加工制动蹄蹄片的专用铣床,此工件原来在车床上加工,切削的蹄片材料是石棉酚醛混合物,存在工人劳动强度大,装卸和夹紧困难,由于材料的特殊性、表面不连续性、以及其结构的复杂性等原因。存在切削时材料不宜脱落,生产效率低等缺陷。为克服以前采用车削加工时所产生的问题,设计了此专用铣床,采用旋转铣削法加工,成功解决了上述问题。

专用机床是通过缩小机床的工艺用途来实现高效率的机床。这类机床结构较简单,调整和操作方便,自动化程度较高,易于保证质量并有较高的生产率。适于成批生产。

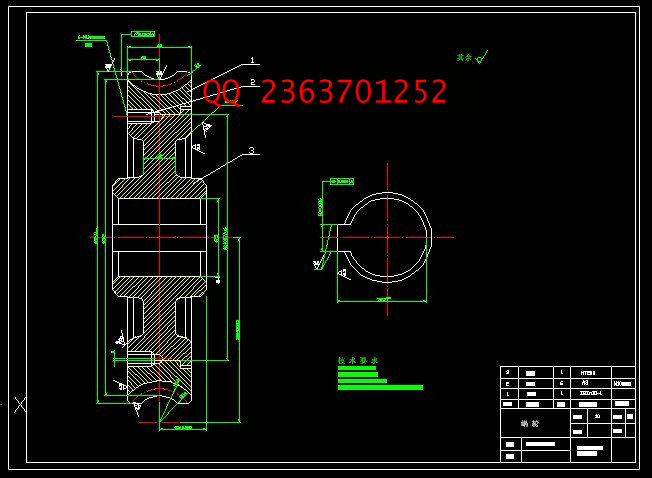

本设计的主要内容为机床的旋转机构和床身部件,床身部件包括减速器,滑台和箱体。减速器采用结构简单的双级圆柱齿轮传动,其整体内置于床身内部,减小了机床的整体结构;通过皮带传动将电动机功率输入其内,其输出端连接机床的旋转机构。旋转机构采用涡轮涡杆传动,控制加工台的旋转。调整机构用于调整铣削头与工件之间的位置关系,以保证工件的加工精度;其结构采用可垂直相对运动的十字滑台结构,运动靠丝杠螺母机构实现并采用了可靠的锁紧结构,既能保证机床结构参数的调整又能保证在加工过程中保持位置不变,可使加工过程顺利进行。

关键词:专用铣床;减速器;旋转机构;十字滑台

Abstract

The design objective is to design a milling machine which can process the brake shoes, the original part was processed in a lathe, cutting the shoes, phenolic mixture of asbestos materials, labour-intensive existence of workers, handling and clamping difficult, because the special nature of the surface discontinuities, and the complexity of its structure and other reasons. There exist two problems :cutting material difficult and low production efficiency .In order to overcome the past by turning on when the problems arising from the design of this special milling machine, used by rotary milling processing, successfully resolve the issue.

Special Machine through the narrow use of the machine tool to achieve high efficiency of the machine. Such a simple machine structure, adjustment and easy to operate, a higher degree of automation and easy to ensure the quality and higher productivity. Suitable for mass production.

The design of the main elements of the rotation for the machine tool and bed parts, components, including bed reducer, slider and Cabinet. Reducer a simple structure of the double-cylinder gear transmission, its overall internal built-in bed, reducing the overall structure of the machine; belt through the motor drive will enter its power, its output connected machine rotating bodies. Adopted by turbine rotating vortex-transmission, processing control of Taiwan's rotation. Adjustment of institutions used to adjust milling head and the location of relations between the workpiece to ensure that the workpiece processing accuracy of its use of the vertical structure of relative movement of cross-Taiwan sliding structure, movement by screw and nut agencies to achieve a reliable locking structure , The machine can ensure that structural adjustment can guarantee that the parameters in the process of keeping the same process can proceed smoothly.

Keywords: dedicated milling machine reducer rotate slide coss-Taiwan

目 录

1 绪论 1

1.1 前言 1

2 专用机床概述 2

3 零件分析与加工方案确定 4

3.1 零件分析 4

3.1.1 零件的用途 4

3.1.2 零件的工艺分析 4

3.2 工艺方案的确定 5

4 机床设计参数的确定 7

4.1 机床参数设定 7

4.2 铣削后圆柱面的侧母线 7

4.3 参数a、b值大小及精度 9

4.4 机床参数确定 10

4.5 铣削用量的确定 11

4.6确定制动蹄片专用铣床总体方案 12

4.7确定制动蹄片专用铣床的传动 14

5 减速器的设计 15

5.1 减速器的类型与选择 15

5.2 电动机的类型与选择 15

5.3 传动装置的总传动比及其分配 16

5.4 计算传动装置的运动和动力参数 17

5.4.1 各轴转速 17

5.4.2 各轴输入功率 17

5.4.3 各轴输入转矩 18

5.5 V型带的设计与选择 18

5.6 齿轮传动设计 19

5.6.1 选择模数 19

5.6.2 齿面接触强度的校核 20

5.7 轴的校核 21

5.8 轴承的选择与校核 24

5.9 键的校核 24

6 滑台的设计 26

6.1 导轨的确定 26

6.1.1 导轨的选择与设计 26

6.1.2 导轨的截面形状与组合 26

6.1.3 导轨间隙的调整 27

6.2 丝杠的选择 27

6.3 滑台的联结 28

7 旋转机构的设计 29

7.1 旋转机构的设定 29

7.2 旋转机构的作用及工作原理 29

7.3 旋转机构的确定 30

结 论 31

致 谢 32

参考文献 33

附录 34

|