|

设计描述:

文档包括:

设计word版本说明书一份,共26页,约10000字

CAD版本图纸,共11张

毕业设计说明书 中文摘要

蚕豆脱壳机

摘要:

蚕豆脱壳机是将蚕豆荚果去掉外壳而得到蚕豆仁的场上作业机械。由于蚕豆本身的生理特点决定了蚕豆脱壳不能与蚕豆的田间收获一起进行联合作业,而只能在蚕豆荚果的含水率降到一定程度后才能进行脱壳。随着蚕豆种植业的不断发展,蚕豆手工脱壳已无法满足高效生产的要求,实行脱壳机械化迫在眉睫。

蚕豆去壳机能否正常运转,看的是其主要部件的设计,如果设计不合理,机器就不能正常运转或者说不能运转,那么生产出来的这台机器就是一堆费品。设计合理,机器就能正常的运转对并对蚕豆果进行剥壳。因此,刮板式蚕豆去壳机的主要部件的设计在整个设计过程中显得尤为重要,合理的设计将提供给使用者更多的方便和实惠。

关键词 蚕豆脱壳机 皮带传动 反复脱壳

毕业设计说明书 外文摘要

Broad bean shelling machine

Abstract

Vicia huller is the fruit throw away outer shell but get shelled Vicia of field top homework machine. Because the physiology characteristics of Vicia comes to a decision Vicia to take off hull and can't be together carry on uniting homework with the in the field results of Vicia, but can then can carry on taking off hull after the Vicia the contain of the fruit water rate decline to certain degree. Because the Vicia plants a continuously develop of the industry, Vicia handicraft's taking off hull has already can't satisfy to efficiently produce of request, practice to turn of the utmost urgency.

Pare off a plank type Vicia to deny a normal operation to the hull function, what to see is it the design of main parts, if design not reasonable, the machine can't normally revolve perhaps say that can't revolve, so the production come out of this set machine is a heap of fee article. Design reasonable, machine ability normal of operation to also carry on shelling hull to the Vicia fruit. Pare off a plank type Vicia to the design of the main parts of hull machine in the whole design process seem to be is importance, reasonable of the design will provide more to the user of convenience and real benefit.

Keyword Vicia huller Belt transmission Repeatedly shell

目录

1 引言 1

1.1 提出课题的背景 1

1.2 蚕豆脱壳机的发展现状 1

1.3 项目研究的目的和意义 2

1.4 主要设计内容和关键技术问题 2

1.5 研究方法与技术路线 3

2 技术任务书(JR) 4

2.1产品设计的依据 4

2.2 产品的用途及使用范围 8

2.3主要技术参数和性能指标 8

2.4主要工作原理 8

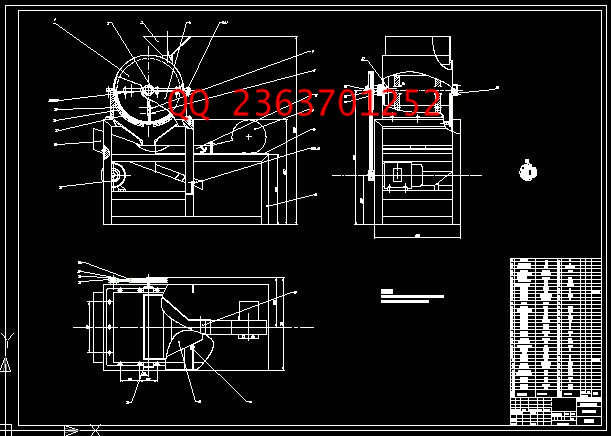

2.5总体结构概述 9

3 设计计算说明书(SM) 10

3.1设计前各项参数的确定 10

3.2 V带传动 13

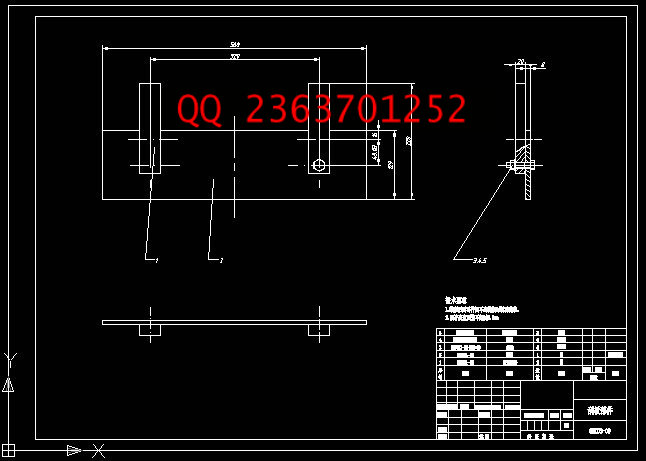

3.3 轴 16

3.4 刮板结构 18

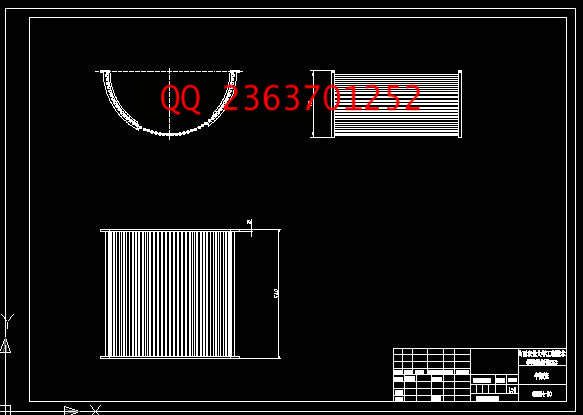

3.5栅笼 19

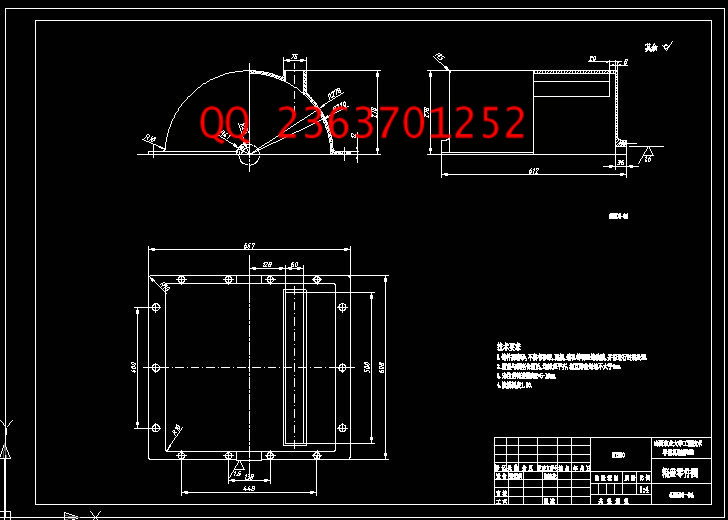

3.6 箱体 20

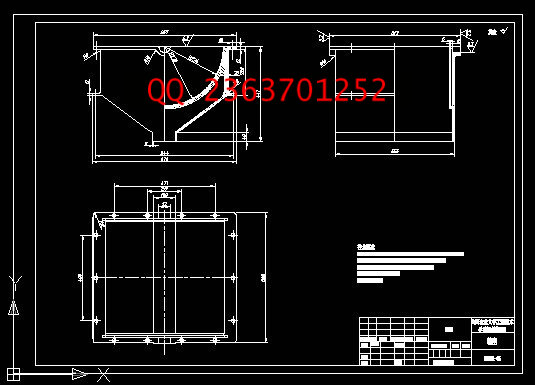

3.7 壳仁分离装置 20

3.8机架 20

3.9附件 20

4使用说明 21

4.1 使用前的准备 21

4.2工作中的管理 21

4.3维护与保养 22

4.4机械安全操作规程 22

5 标准化审查报告(BS) 23

5.1产品图样的审查 23

5.2产品技术文件的审查 23

5.3标准件的使用情况 23

5.4审查结论 24

6 总结 24

参考文献 25

致谢 26

|