|

设计简介 |

设计描述:

文档包括:

设计word版本说明书一份,共31页,约12000字

CAD版本图纸,共7张

去毛刺专用机床电气控制系统设计

机械毕业设计/论文

摘 要

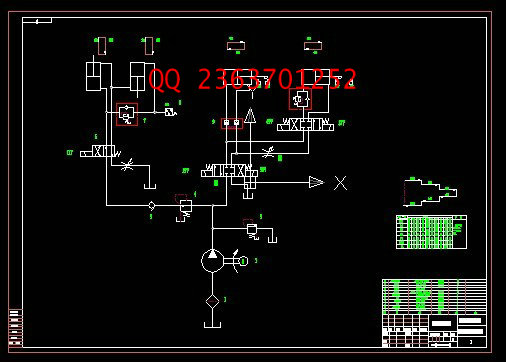

本次设计的去毛刺专用机床是适用于生产进行加工过程中零件产生的毛刺去除。由于该机控制系统采用了先进的电气、液压与机械紧密结合,动作程序互锁、监控严格的程序控制系统,所以具有自动化程度高、生产能力强、操作简单可靠和维修方便等特点。主要进行了对电气控制系统的改进,在以前继电器控制系统产品的基础上,采用了工业控制专用计算机——可编程控制器控制系统。在PLC及外部电气系统控制下,通过控制进给油泵电机、主轴电机、冷却电机、等三个电磁阀的逻辑程序动作,完成去除各类零件的毛刺任务。

此次毕业设计,是根据生产机械的控制要求,去毛刺专用机床电气控制系统的设计和完成电控装置在制造、使用和维护过程中所需的图样和资料,要求利用功能和优点较为齐全的可编程控制器(PLC)来对去毛刺电气控制系统进行控制及运行,以及机床电气控制对系统液压回路的控制来完成整个零件加工过程的动作要求,从而来完成整个操作过程中的各项任务。

关键词:主轴电机、去毛刺电气控制系统、机床电气控制、PLC

Deburring special purpose machine electric control system design

ABSTRUCT

This design's deburring special purpose machine is suitable in the production carries on the burr elimination which in the processing process the components produce. Because this machine control system has used the advanced electricity, the hydraulic pressure and the machinery unifies closely, acts the procedure interlock, the monitoring strict programmed control system, therefore has the automaticity to be high, productivity is strong, the simplicity of operator is reliable and characteristics and so on service convenience. Mainly has carried on to the electric control system's improvement, in the beforehand black-white control system product's foundation, has used the industrial control special purpose computer - - programmable controller control system. In PLC and under exterior electrical system control, through the control to feed oil pump electrical machinery, the main axle electrical machinery, cools the electrical machinery, and so on three solenoid valve's logical program movements, completes removes each kind of components the burr duty.

This graduation project, is according to produces machinery's control request, the deburring special purpose machine electric control system's design and completes the electrically controlled installment the pattern which and the material in the manufacture, the use and the maintenance process needs, requests (PLC) comes using the function and a merit more complete programmable controller to the deburring electric control system to carry on the control and the movement, as well as the engine bed electric control completes the entire components processing process to the system hydraulic circuit's control the movement request, thus completes in the entire operating process each duty.

KEY WORDS:Main axle electrical machinery, deburring electric control system, engine bed electric control, PLC

目 录

摘要--------------------------------------------------------------------3

一、概述---------------------------------------------------------------4

(一)电气控制系统-------------------------------------------------4

(二)可编程序控制器-----------------------------------------------4

(三)设计任务及要求-----------------------------------------------6

二、机床电气控制流程的设计---------------------------------------------7

(一)设备名称、用途、工艺过程及技术性能---------------------------7

(二)电源---------------------------------------------------------8

(三)对电气控制特性要求-------------------------------------------8

(四)电气传动-----------------------------------------------------8

(五)有关操作功能及控制系统选择-----------------------------------9

三、机床电气控制系统的设计--------------------------------------------10

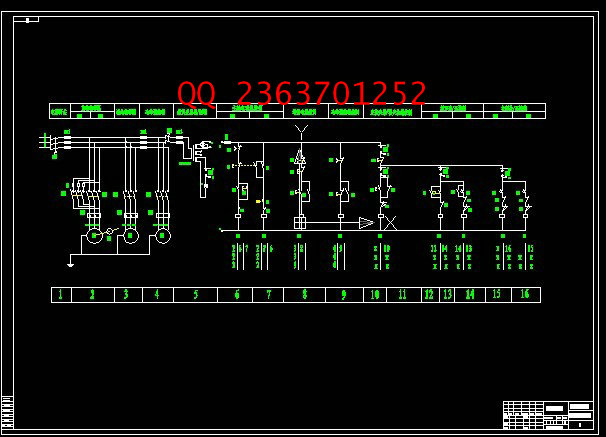

(一)主电路控制设计---------------------------------------------10

1.主电路设计--------------------------------------------------10

2.中间继电器--------------------------------------------------10

(二)执行电路控制设计--------------------------------------------10

1.机床电气传动的特点及控制要求--------------------------------10

2.控制电路电源------------------------------------------------11

(三)辅助电路设计-----------------------------------------------11

1.信号指示与照明电路------------------------------------------11

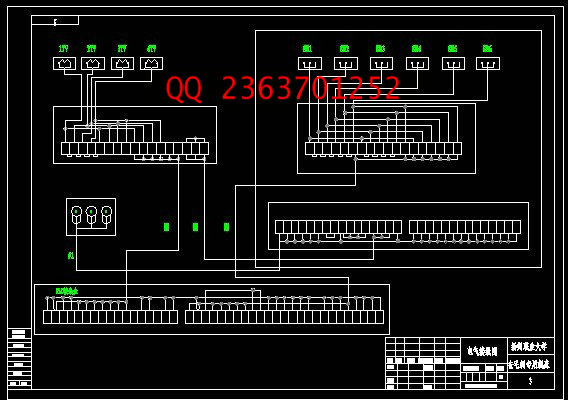

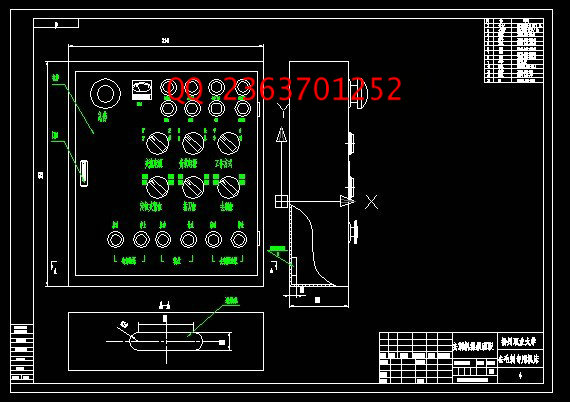

2.控制箱------------------------------------------------------12

3.操纵箱------------------------------------------------------12

4.面板设计----------------------------------------------------12

(四)绘制电气原理图---------------------------------------------12

四、电气元器件型号的选择----------------------------------------------13

五、编程的调试与PLC的选用--------------------------------------------16

(一)调试与运行--------------------------------------------------16

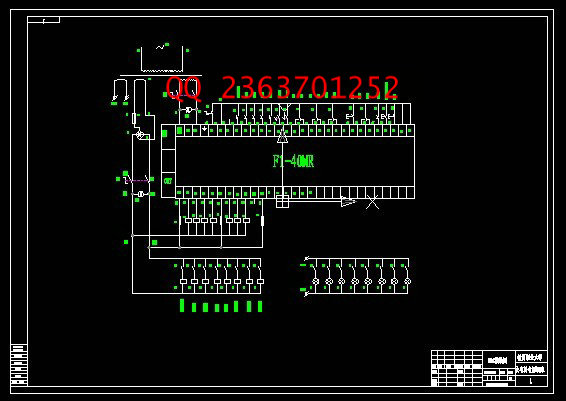

(二)可编程控制器(PLC)的选用------------------------------------17

1.控制要求---------------------------------------------------17

2.输入输出配置-----------------------------------------------17

3.工作方式与梯形图-------------------------------------------18

六、结论与体会-------------------------------------------------------23

1.结论----------------------------------------------------------23

2.体会----------------------------------------------------------23

谢辞-----------------------------------------------------------------25

参考文献-------------------------------------------------------------26

附图-----------------------------------------------------------------27

|