|

设计简介 |

设计描述:

文档包括:

设计word版本说明书一份,共34页,约17000字

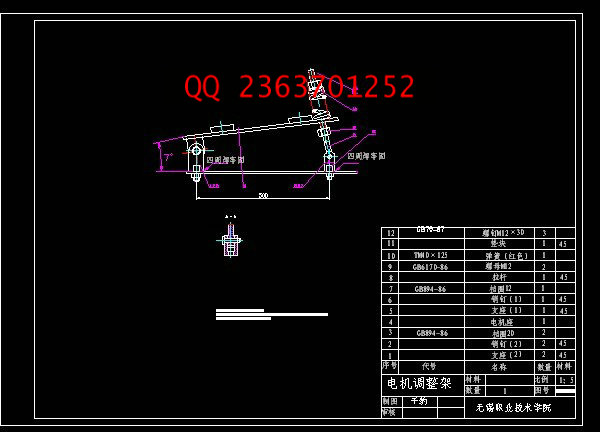

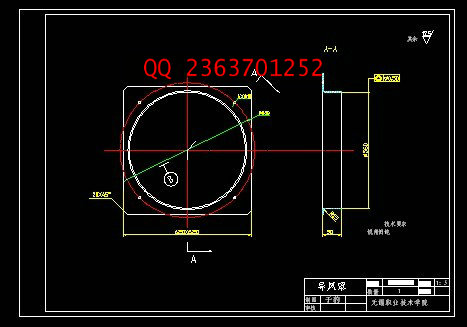

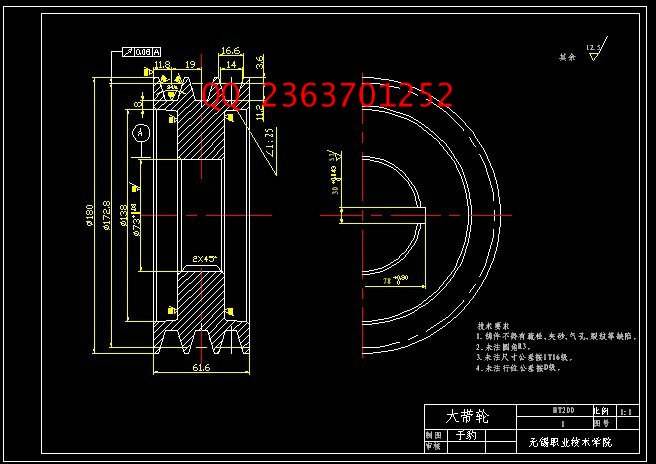

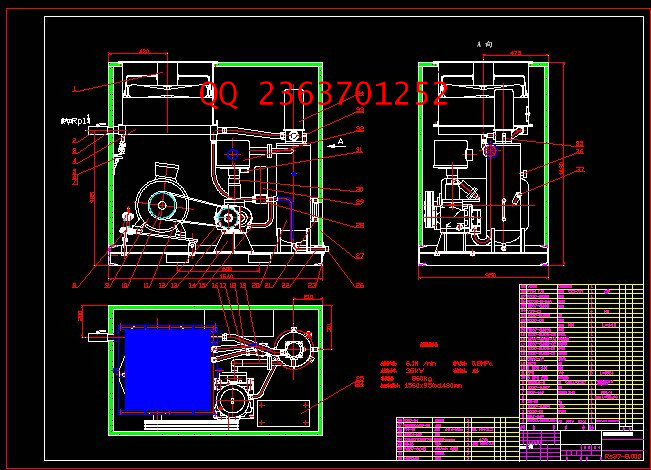

CAD版本图纸,共13张

图纸共13张:

摘 要

通过在压缩机厂家的学习和网上资料结合,本次设计将简单介绍空气压缩机吸气、排气过程的工作原理和有效减小噪音的方法。

吸气、排气过程是在压缩缸里完成的。影响其吸气或排气量的因素有转子直径、转子长度;P(压力)、T(温度)、海拔高度、n(转速)、V(余隙容积)、泄漏等。前者属于设计因素,而后者属于运动因素。合理的运用这些因素可以有效的提高压缩机的工作效率,从而提高生产率。

噪音是是令人讨厌或干扰的声音,在压缩机工作的同时还会发出不同程度的噪音,影响工作人员的身心健康。有效得减小噪音事在必行。

减小噪音的主要方法有1、保机体中的所有接头是安全的,叉车孔关闭,机组地面的基体是固封住的。2、通过管道输送进气和排气。 3、减少反射噪声。通过以上3点设计和预防,进一步减小产生的噪音。此外,还有不少减小噪音的途径。通过种种减小噪音的方法,使压缩机真正的实现规范化,符合国家规定的标准。

关键词:压缩机,V形带,螺杆,噪音.

By compressor manufacturers in the study and on-line information integration, this will be designed to brief air compressor suction, exhaust the process of working principle and effective method of reducing noise.

Suction, exhaust in the compression process is completed Gang Li. Breathing or affect its emissions factors rotor diameter, the length of the rotor; P (pressure), T (temperature), altitude, n (speed), V (MS gap volume), the leakage. The former are design factors, which are factors campaign. Reasonable use of these factors can effectively improve the efficiency of the compressor, thereby improving productivity.

Yes yes noise nuisance or interfere with the voice of the compressor will be issued at the same time the work of different levels of noise and affect the physical and mental health staff. Effective in reducing noise is inevitable.

The main method of reducing noise there, in all-body joints are safe, forklift hole closed, the ground crew is solid matrix sealed. 2, piped through the intake and exhaust. 3, reducing reflection noise. Through the above 3:00 design and prevention, and further reduce the noise generated. In addition, there are many ways of reducing noise. Reduce noise through a variety of methods, to achieve real standardization compressor, in line with the state standards.

Key words: compressor, V-shaped belt, screw, noise.

目录

CAD中英文对照…………………………………………………………………………………..1

课题报告…………………………………………………………………………………………..10

第一章 引言…………………………………………………………………………11

第二章 螺杆压缩机的介绍..........................................................................12

一.发展历程…………………………………………………………………...12

二.发展方向…………………………………………………………………...12

三.螺杠压缩机的研究意义…………………………………………………...13

四.螺杠压缩机的原理………………………………………………………...15

五.螺杠压缩机的操作规程…………………………………………………..16

第三章 参数及选取原则................................................................................19

3.1.型线参数……………………………………………………………...........19

3.1.1型线种类……………………………………………………………...19

3.1.2转子齿数……………………………………………………………...19

3.1.3齿高半径 ……………………………………………………………20

3.1.4齿顶高………………………………………………………………...20

3.2转子结构参数……………………………………………………………….20

3.2.1转子直径和长径比…………………………………………………...20

3.2.2导程和和扭转角……………………………………………………...20

3.2.3排气压力和吸气压力………………………………………………...21

3.2.4压缩机的排量………………………………………………………...21

第四章 电动机的选择及V带的设计............................................................22

4. 1电动机的型号………………………………………………………………22

4.2 V带的设计…………………………………………………………….........22

4.3螺杆压缩机的功率………………………………………………………….25

第五章.噪音及减小噪音的途径…………………………………………………....26

5.1噪音………………………………………………………………………….26

5.2噪音的测量………………………………………………………………….26

5.3噪声防止途径……………………………………………………………….28

第六章 结束语.......................................................................................30

第七章 参考文献……………………………………………………………………31

第八章 附录…………………………………………………………………………32

第九章 感谢信.......................................................................................34

|