|

|

|

|

设计名称 |

自走式烟苗剪叶机整体机构的设计[农业机械] |

|

|

设计编号 |

W203 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

12000字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

2013.09.26 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

设计描述:

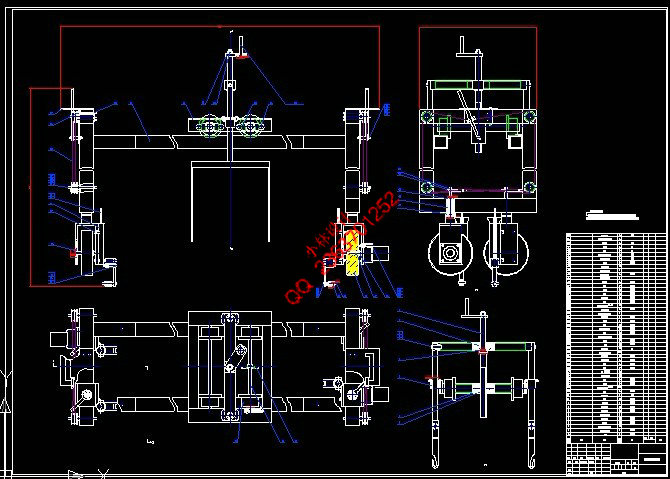

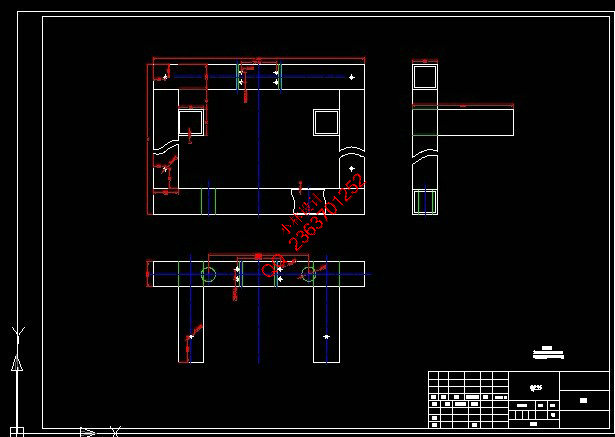

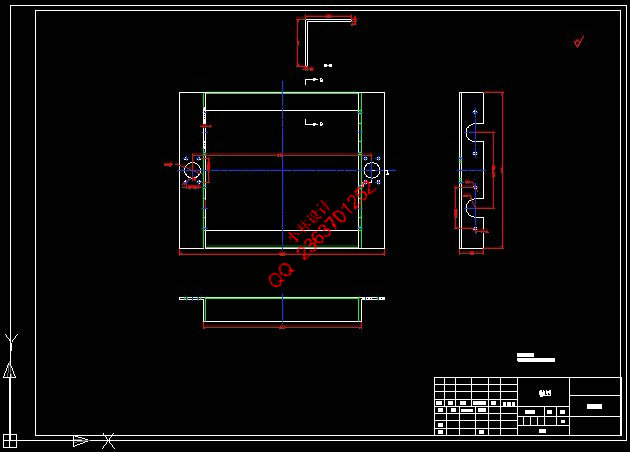

文档包括: CAD版本图纸,共25张 目 录

摘要……………………………………………………………………………………1 自走式烟苗剪叶机的设计

摘 要: 一种自走式烟苗剪叶设备,包括机架组件和剪叶小车;在温室烟苗池两边有一对水泥轨道,机架组件底部的车轮可以在上面行走;在机架上还有使剪叶设备整体跨间转移的机构组件;剪叶小车的剪叶机机头组件垂吊在机架横梁的下方,通过一驱动电机驱动,可以在横梁滚动行走。剪叶小车通过电机驱动,实现剪叶设备的无极调速。螺杆和螺母的滑动螺旋可以调控剪叶机头的剪叶高度,实现剪叶设备在育苗盘上方的前后、左右、上下方向剪叶作业;通过机架组件实现剪叶机跨间转移,实现剪叶机多功能作业。 Design of Self-moving Tobacco Seedling Leaf-cutting Machine

Abstract: A self-propelled Tobacco seedlings cutting device, comprising a frame assembly and a leaf cutting trolley; each cultivate greenhouse tobacco seedlings Medium pool’s both sides have a pair of cement rail, so that rack assembly bottom wheels can walk on it; and there is a mechanism component on the frame which can make the whole span leaf cutting device transfer; leaf cutting trolley‘s leaf cutting machine head assembly are hanging under the Rack beams ,which drived by a driving motor so that can roll along the beam. Leaf cutting trolley which is driven by the motor can make the cutting devices non level speed control, the screw and the nut’s Slide helix can Regulate leaf cutting head leaf‘s cutting height , so that the leaf cutting device which above the seedling traycan work from around, up and down; through the Rack components which can make leaf cutting machine span transfer and realize Achieve multiple functions. |

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1