|

设计简介 |

文档包括:

word说明书一份,共39页,约13000字

CAD版本图纸,共16张

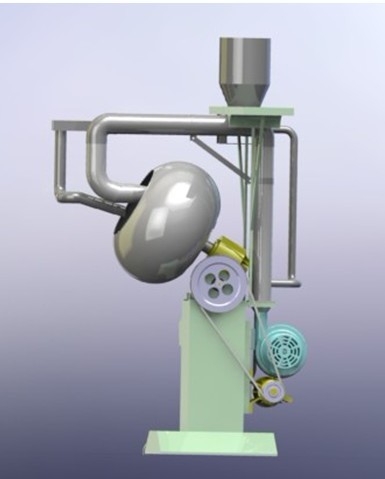

SW三维图一份

图纸共16张,如下所示

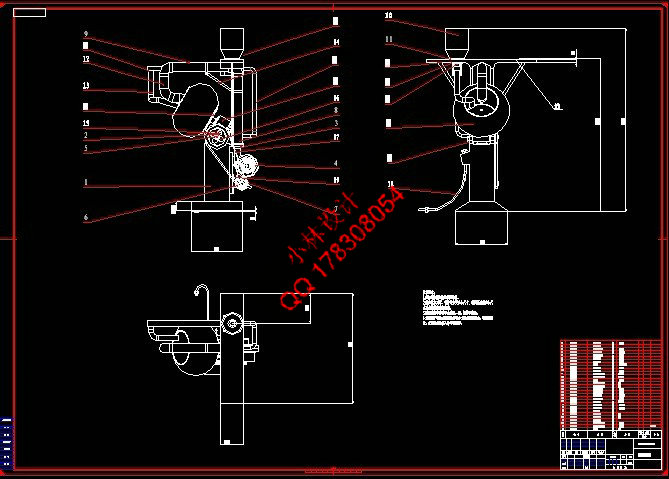

A0-总装配图.DWG

A1-整体机构.DWG

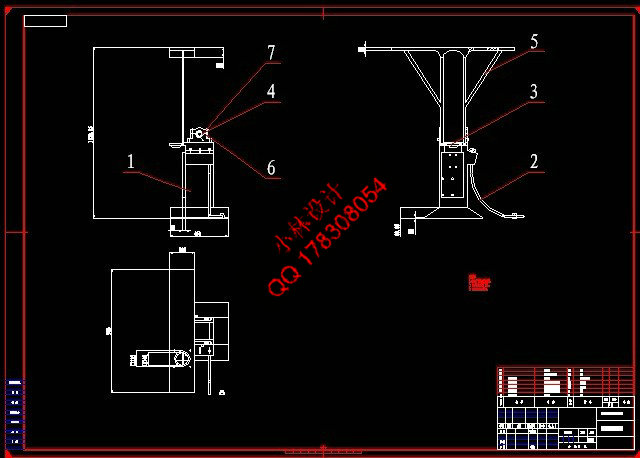

A2-供热整体.DWG

A2-供粉装置整体.DWG

A2-带传动.DWG

A2-裹衣装置.DWG

A3-大带轮.DWG

A3-小带轮.DWG

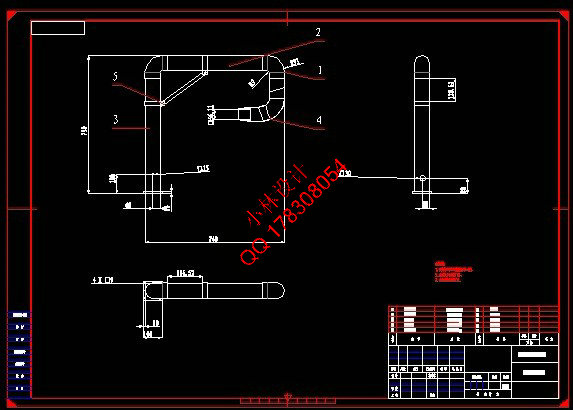

A3-支架.DWG

A3-轴承端盖.DWG

A4-供热连接件.DWG

A4-挡粉板.DWG

A4-排风管.DWG

A4-档位套环.DWG

A4-粉仓固定.DWG

A4-粉料仓.DWG

种子裹衣机设计

摘 要

林木种子的裹衣是种子处理中的一项具有开发前景的新技术。它是利用专业用的配套设备,按着一定特有的工艺流程和物料配方方案所完成的种子规格化处理技术。它通过粘合剂将物料包裹在种子的表面,形成一定厚度的衣壳,使种子的外形尺寸达到规格化,就可便于实现机械化作业。采用种子裹衣加工不可以改善种子形状,还能改善其强度等物理特性,为一些小颗粒的种子,还有不规则的种子创造良好的条件,可以促进它们的生长,同时也能节约成本、保护环境,对保障食品的安全起到了重要的意义。

本文首先介绍了种子裹衣技术的背景、概念、意义、目的、设计要求其裹衣技术的加工原理以及其加工工艺过程和发展展望。然后在此基础上,对所研发设备的关键零部件进行选型,改良设计。特别介绍了种子裹衣机的结构以及设计重点,介绍了国内外的研究现状。并对种子裹衣机的发展前景做了简要叙述。

根据其加工工艺,设计供粉装置,进一步完成裹衣整体设备的方案设计。优化了供粉装置,使其装置更简便,更轻巧。将原设备上的带传动转动起风改成了鼓风机供风,使其简单化,而且也增强了供风的稳定性。为了能准确,简单的控制裹衣锅的倾斜角度,从原有的基础上,在减速箱的外壳和轴承端盖上加了档位器,使其简单的控制裹衣裹的倾斜角度。

我国种子裹衣技术才刚刚起步,还需要进行全方位地提高,这是一个任重道远的过程。可喜的是国家对这个产业的投入不断增加,种子企业对其的关注不断的提高。我们相信,通过正确的引导,理论的完善,科研水平的不断进步以及整个种子领域对质量要求的不断提高,在不久的将来,我们会逐渐缩短与发达国家的差距,从而为种子公司带来更大的利润,为农民减少投入、增加收益。

关键词:种子;裹衣技术;优化设计;发展展望

Forest Seed Coating Machine Designing

Abstract

Cloak of tree seeds is a new promising technology in seed treatment. Following specific technological process and material formula solution, it is a normalization technology of seed using appropriative corollary equipment. The material is wrapped outside the surface of the seed by adhesive as a capsid in order to normalize the seed shape and realize mechanical operation. Cloak-treating can not only change the seed shape, but also improve its physical properties, such as strength. It can provide a good environment for seeds of small and irregular shape and boost their growing. At the same time, cloak-treating can reduce the cost and protect the environment, which is meaningful to guarantee food security.

This paper introduces the background, concept, meaning, aim of cloak-treating, the processing principle the design requires, the operational process and the development prospect. On this basis, key components of the designed equipment are chosen and improved, e.g. gyration kettle, powder-offer device, heating arrangement, the whole frame, etc. This paper especially introduce the structure and design emphasis of cloak-treating equipment, the research status both at home and abroad as well as the brief description of its development prospect.

According to its operational process, powder-offer device is designed to complete the whole equipment. It optimizes the powder-offer device, which is made to be more simple and convenient. Wind is blown from turning to fanning, which is more simple and strengthen the stability of wind- supply. In addition, gear position indicator is added outside the reducer and in the bearing end in order to control the gradient of cloak easier and more accurate.

Cloak-treating technology is just starting out in our country and still needs improving in all directions, for which we shoulder heavy responsibilities and have a long way to go. The good news is that China is increasing the investment in this industry and seed enterprises are paying more attention to this technology. We believe we will gradually shorten the gap with developed countries in the coming future through proper guidance, impeccable theory, progressive science technology and elevated requirements for seed quality, thus seed enterprises will gain more profits, and farmers can also cut inputs and increase revenues.

Key Words: seed, cloak-treating technology, optimized design, development prospect

目 录

第一章 绪论 1

1.1引言 1

1.2 国内外种子裹衣机发展现状 2

1.2.1 国内种子裹衣机现状 3

1.2.2 国外种子裹衣机现状 5

1.3 本文研究的目的及其展望 6

第二章 种子裹衣机整体设计方案确定 9

2.1 种子裹衣机的设计要求及类型 9

2.1.1 种子裹衣机的设计要求 9

2.1.2 种子裹衣机的类型及比较 9

2.1.3 种子裹衣机使用时应注意的问题 9

2.2 裹衣机整体设计方案确定 10

2.2.1 裹衣机的工作原理 10

2.2.2 裹衣机总体结构设计与创新 10

第三章 种子裹衣机结构设计 11

3.1传动机构设计与选型 11

3.1.1电机的选型 11

3.1.2 同步带传动设计 11

3.1.3减速器的选型 15

3.2 关键部位选型与设计 16

3.2.1 回转釜装置选型 16

3.2.2 供热装置设计 18

3.2.3 供粉装置设计 20

3.3 整体机构的设计 23

第四章 结构强度校核 29

第五章 总结和展望 31

5.1总结 31

5.2展望 31

致谢 32

参考文献 33

附录 34

|