|

|

|

|

设计名称 |

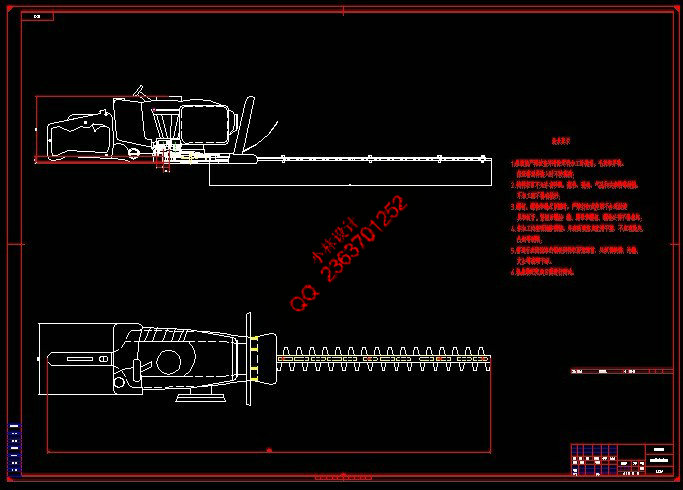

双刃面绿篱修剪机的设计 |

|

|

设计编号 |

W234 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

13000字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

2013.09.26 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

文档包括: CAD版本图纸,共15张

摘要 Abstract

3,the job quality is better and stable performance.

4,a multi-purpose machine,both as a hedge trimmer shaping,but also as a lawn edges.

Keywords hedge trimmers reciprocating double-face 目录

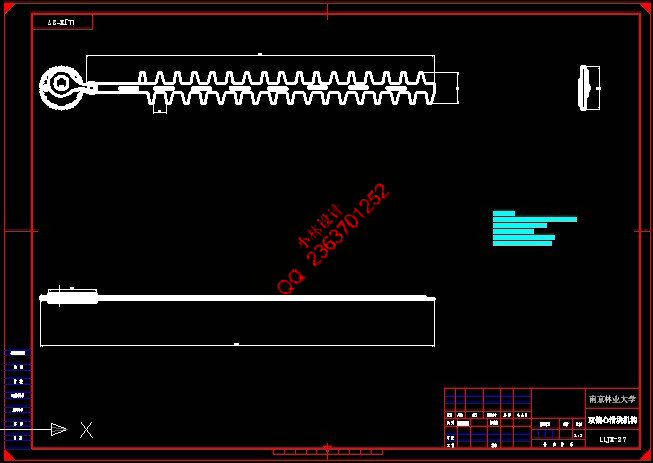

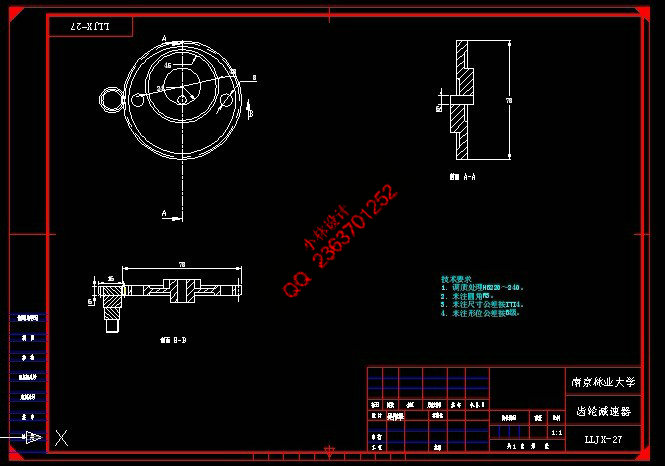

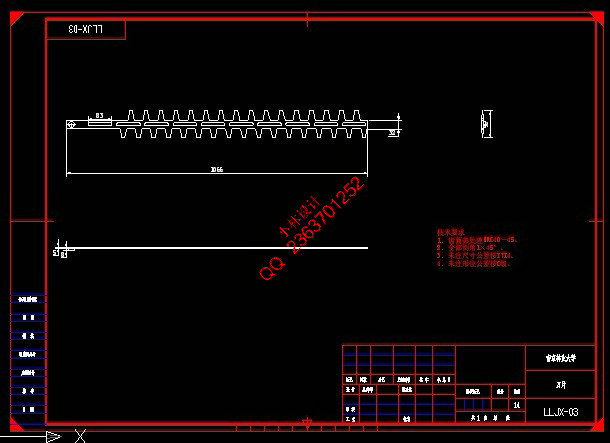

1.1 绿篱修剪机的发展................................................................. 6 1.1.1、国内外发展概况......................................................... 6 1.2 对绿篱修剪机的认识............................................................. 7 2 整体设计........................................................................................ 10 2.1 技术设计的要求................................................................... 10 2.2 传送路线的拟定................................................................... 10 2.2.1 对传动方案的要求......................................................10 2.2.2 拟定传动方案.............................................................. 10 2.3 绿篱修剪机的组成及工作原理........................................... 11 3 设计内容........................................................................................13 3.1 发动机的选择....................................................................... 13 3.2 离合器的设计....................................................................... 14 3.3 减速器的设计....................................................................... 20 3.3.1 初定减速器的类型......................................................21 3.4 刀具的设计..........................................................................26

3.4.1 刀片结构的设计及材料的选择..................................26

4 绿篱修剪机操作规程.................................................................... 28 5 绿篱修剪机的操作顺序................................................................ 29 5.1 修剪机的操作顺序............................................................... 29 6 绿篱修剪机的维护........................................................................30 6.1 维护保养要点....................................................................... 30 6.2 操作使用要点....................................................................... 30 7 绿篱修剪机的故障及排除............................................................32 7.1 起动机故障排除方法........................................................... 32 7.1.1 起动困难故障排除方法..............................................32 7.2 绿篱修剪机故障及排除方法...............................................34 7.2.1 修剪机绿篱修剪机故障排除方法..............................34 致 谢............................................................................................... 38 参考文献........................................................................................... 39 附录................................................................................................... 40 |

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1