|

文档包括:

word说明书一份,共35页,约12500字

CAD版本图纸,共7张

木材刀具切削试验台整体设计

摘要

本文主要是进行木材刀具切削实验台的整体设计的构思。我们所设计的木材刀具切削试验台采用驱动链轮轴和进给速度无极调速的运动形式,能测出切向切削力,驱动链轮轴扭矩,链切削速度和进给速度。而大多数国内外切削试验台装置并不能测定以上全部参数,有的参数测定精度也很低。

根据目前国内外现有的切削试验台品种规格多,适用于不同的电链锯,且工作时的锯链切削速度高低差异很大,切削功耗相差很大。为能评定锯链切削木材时的切削性能,所设计的试验台,需能模拟锯链的工作状态,反映锯链实际的切削速度和切削效率,因此应具有较宽的切削速度调节范围和进给速度调节范围;同时应具有较大的传递扭矩,可保证大节距高效率的锯链性能测定。

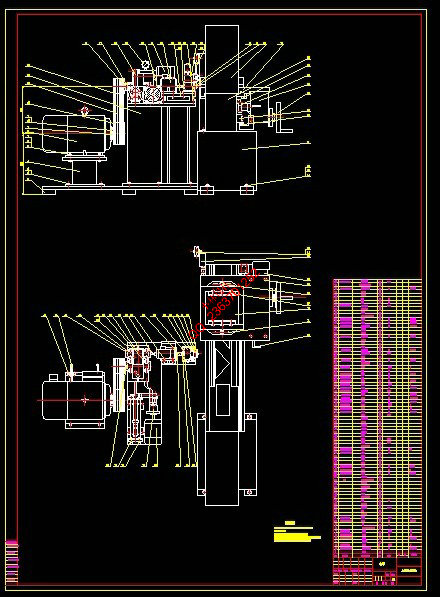

本文阐述了木材刀具切削试验台的总体方案设计,构造及功能,驱动链轮轴,导板支撑座等部件的设计,以及木材刀具切削试验台的电控电路设计。

关键词:试验台设计切削 变频调速

Wood cutter cutting test-bed design literature review as a whole

Abstract

In this paper, the idea of a wood cutter cutting the overall design of the experiment station.Wood cutting tool designed test rig should be able to measure the tangential cutting force, the drive chain axle torque, chain cutting speed and feed rate.

While most of the cutting test at home and abroad station apparatus and can not be measured all of the above parameters, and some parametric measurement accuracy is also very low. Difference in the level of the saw chain when cutting speed and cutting test rig varieties and specifications applicable to electric chain saws, and work, cutting power consumption is a big difference.

Cutting performance when cutting wood saw chain can be assessed, the test stand design, can simulate the working condition of the saw chain, to reflect the actual cutting speed and cutting efficiency of the saw chain and therefore should have a wide cutting speed adjustment range and into the ; the same time should have a larger transfer torque, can ensure the high efficiency of the large pitch saw chain performance measurement to the speed adjustment range.

Keyword:Test rig design cutting frequency control

目 录

1.绪论 3

1.1研究的意义及目的 3

1.1.1研究的意义 3

1.2.1研究的目的 4

1.2 国内外同类研究概况 4

1.2.1 国内研究概况 5

1 .2. 2 国外研究概况………………………………………………….6

1. 2 .3 结论…………………………………………………………….7

2.木材刀具切削试验台设计的主要内容及要求....................................... 9

3总体方案的确定 10

3.1木材刀具切削试验台的功能原理 10

3.2驱动链轮轴转矩转速的测量 10

3.3切削力的测量 11

3.4驱动装置的设计 11

3.5进给装置的设计 12

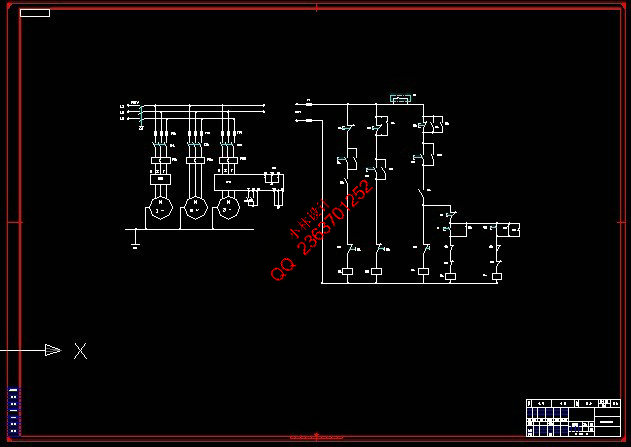

3.6电控电路的设计 12

4木材刀具切削试验台的构造 13

5木材刀具切削试验台的部件设计 15

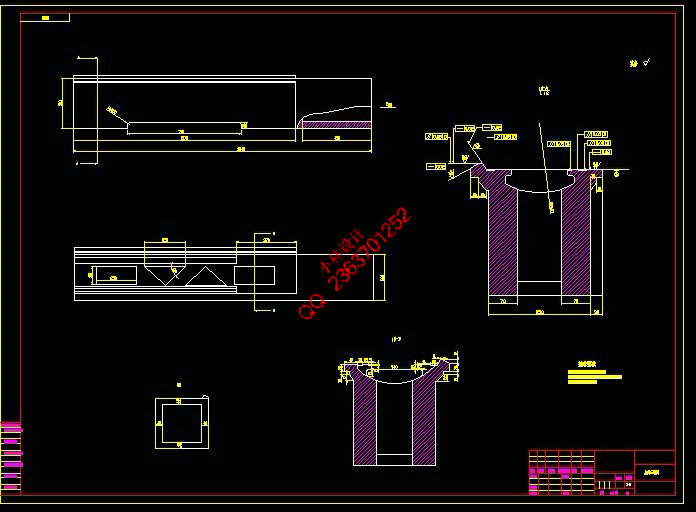

5.1驱动链轮轴的结构设计.................................................................15

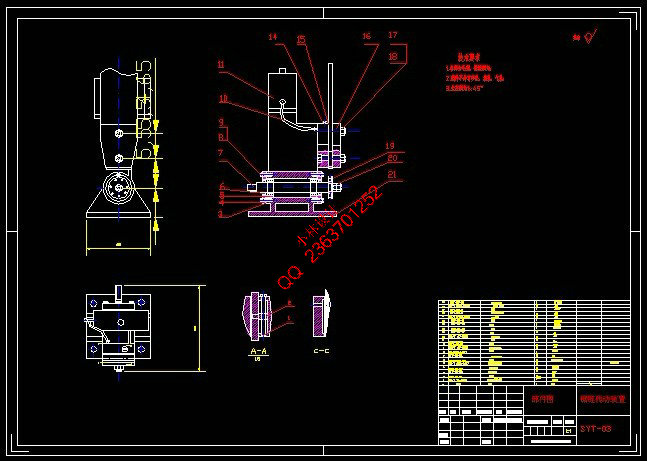

5.2导板支撑装置的设计 17

5.3锯链张紧装置的设计.................................. 18

5.4驱动链轮的设计………………………………………………….19

5.5床身的设计……………………………………………………….19

5.6木材刀具切削试验台的电控电路设计………………………….20

6.木材刀具切削试验台的总装配图………………………………………26

7.测试方案设计……………………………………………………………27

8.总结和展望................................................................................................28

8.1总结...................................................................................................28

8.2展望...................................................................................................28

致谢 29

参考文献 30

附 录 32

|