|

|

|

|

设计名称 |

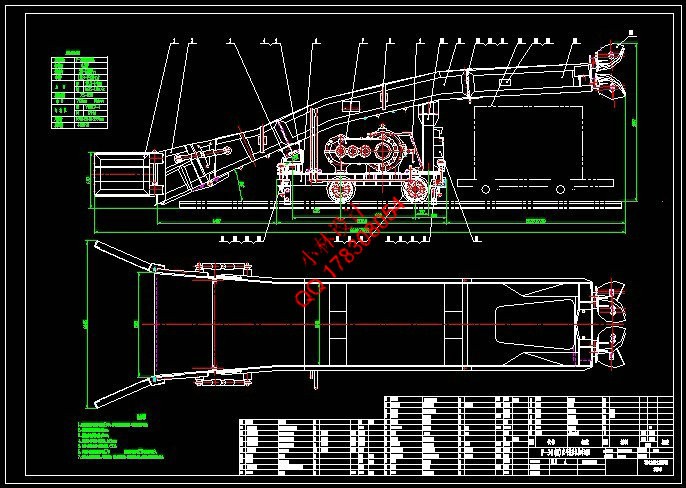

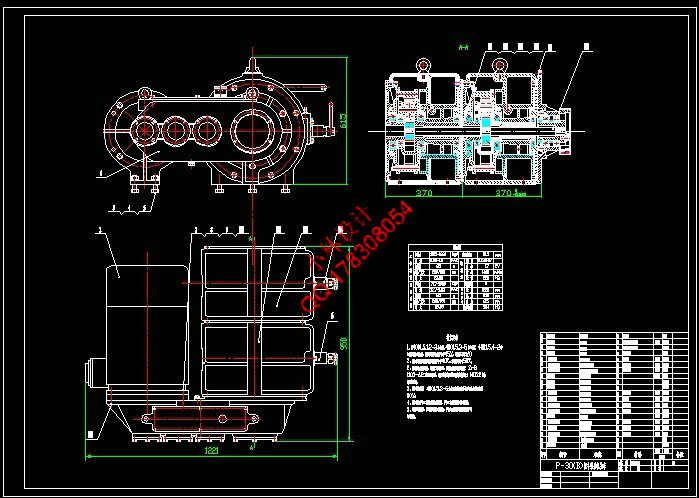

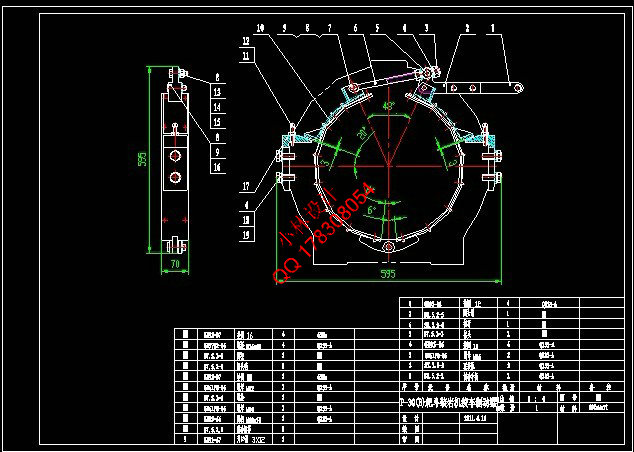

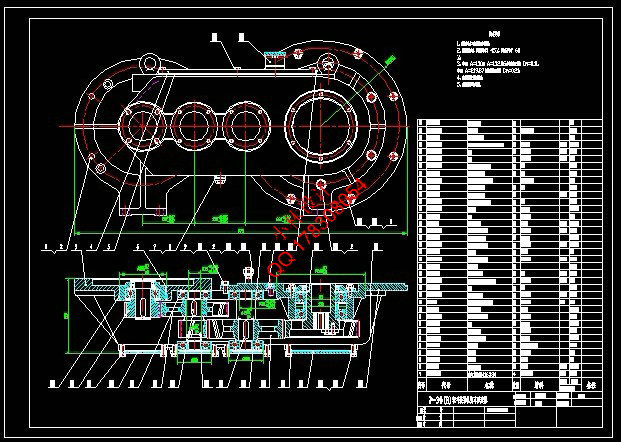

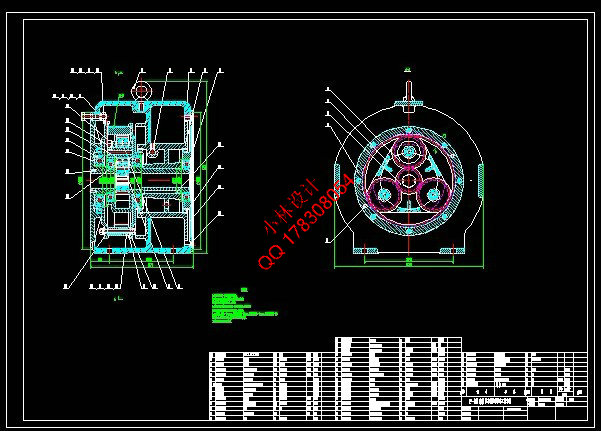

P-30(B)耙斗装岩机绞车设计[矿山机械] |

|

|

设计编号 |

W303 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

22000字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

2014.2.12 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

文档包括:

word版设计说明书一份,共41页,约22000字

CAD版本图纸,共13张

P-30(B)耙斗装岩机绞车设计

学 生:

指导老师:

摘 要:P-30(B)耙斗装载机属于矿井巷道掘进的装岩设备,是耙装机和转载机“合二为一”的机型。可称之为

转载式耙斗装岩机。为了适应大断面矿井快速掘进的要求,从而解决装载速度不能满足掘进速度要求的矛盾,

论文中以耙斗装岩机的生产率和耙斗容积为已知条件,通过大量的计算、推理和论证,设计了耙斗装岩机绞车

部分的减速器、工作滚筒、空程滚筒、制动器等绞车主要部件。本设计中工作滚筒和空程滚筒的传动部分采用

行星齿轮机构来完成,并对行星齿轮传动系统均载的基本原理做了简单的说明。这样就使得按该方案设计的绞

车具有操作省力、灵活,调整简便,事故少,维修工作量小的优点,同时在吸取成型产品生产和使用经验的基

础上完成了耙斗装岩机的绞车设计。

关键词:绞车;电动机;滚筒;变速箱;制动器

Design of P-30(B) Rake Bucket Rock Loader Winch

Student: u

Tutor: u

Abstract: P-30 (B) rake bucket loader is installed to mine rock Tunneling Equipment, is a rake

and loader installed "combined" models. Reprinted type rake may be called to rock loader bucket.

Large section of mine in order to meet the requirements of fast driving, in address loading speed

can not meet the requirements of the contradictions driving speed, paper, rock loader bucket with

rake and rake the productivity of the buckets of known conditions, through a large number of

calculations, reasoning and argumentation, designing to rake bucket rock loader winch part of the

reducer, the working cylinder, air-way roller, brakes and other key components winch. The design

of the work rollers and air-way roller planetary gear transmission part is to be completed, and

the planetary gear transmission system. The basic principles are set out in a simple description.

This shide in accordance with its design of the winch with operational effort, flexible, easy to

adjust, less accidents, maintenance workload of small advantages, while on the basis of learning

from the experience of molding products and using a rake the complet of the winch rock loader

bucket design .

Key words:winch;electric motor;roller;transmission;brakes

目 录

摘要.........................................…….. 1

关键词........................................................................ 1

1 前言........................….................…....................2

1.1 耙斗装岩机绞车概述..................................... .....2

1.2 国内外研究现状.....................................……................... ...3

1.3 本文选题的目的及来源......................…………………4

1.4 本设计的主要内容........................................................4

2 绞车方案设计......…….............................………………5

2.1 绞车的功能、原理..................................................... ..5

2.2 组成绞车主要部件形式设计................................ 6

2.3 绞车传动方案设计及结构特点.....................................11

2.4 绞车方案的对比分析及优选........................................11

2.5 方案可行性分析..................................................13

3 绞车性能参数设计...……..........…...........………………...15

3.1 纹车基本参数确定...……..............……..……....15

3.2 绞车主要零部件参数设计计..........…........16

4 绞车结构设计..............................………………....23

4.1 绞车总体结构设计.............…………....…….......23

4.2 绞车部件结构设计.................…….................….....25

4.3 零件的结构设计......……........................…............…....26

5 绞车强度设计……......................……..........................................27

5.1 行星齿轮传动均载分析.....................…...............................29

5.2 行星轮系中心轮设计计算................….................................32

5.3 绞车主制动器的设计计算................…..................................36

6 结论……............…......................................................39

参考文献.............................................................................40

致 谢.............……........................….............………………...41

|

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

声明:根据《互联网传播权保护条例》本站,小林机械资料商城,所列资料均属原创者所有,仅供学习交流之用,请勿转载并做其他非法用途。

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1