|

|

|

|

设计名称 |

侧边传动式旋耕机的设计[农业机械] |

|

|

设计编号 |

W305 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

12000字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

2014.2.12 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

文档包括:

word设计说明书一份,共26页,约12000字

任务书一份

开题报告一份

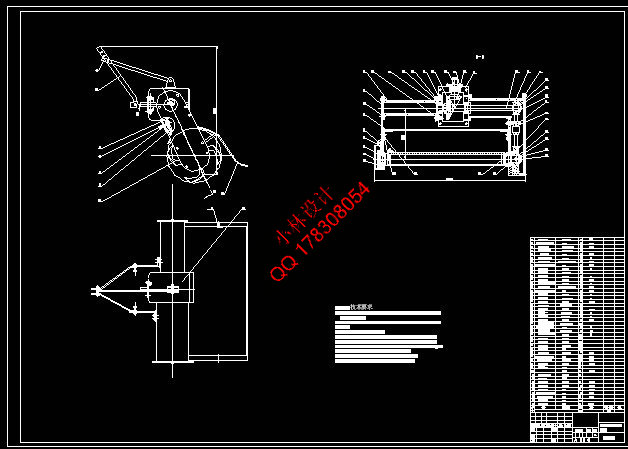

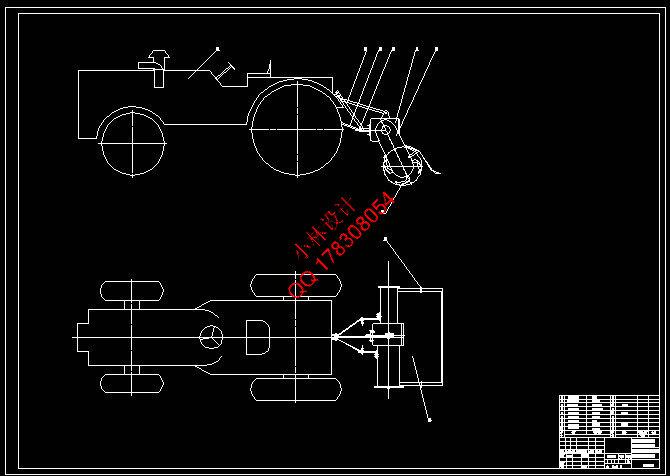

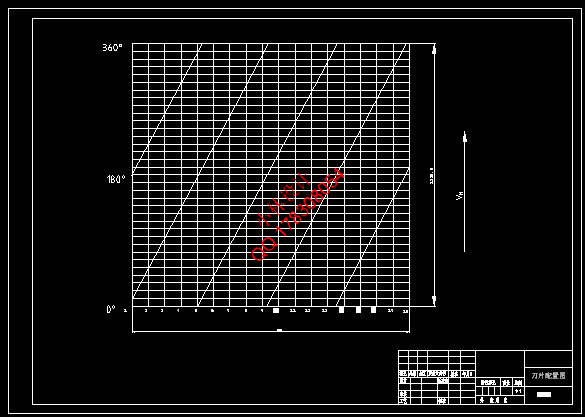

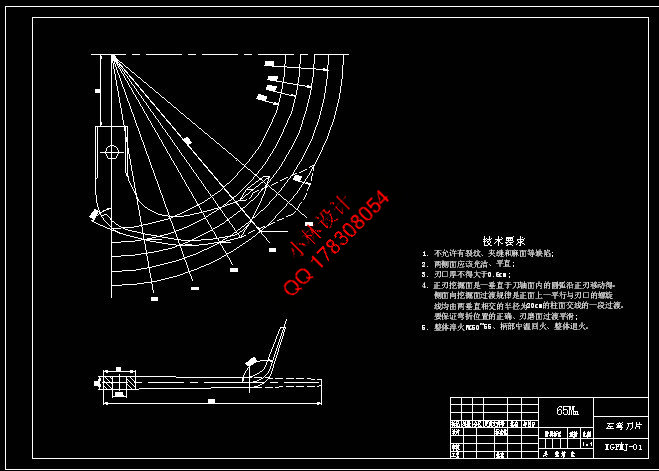

CAD版本图纸,共9张

侧边传动式旋耕机的设计

摘 要:旋耕机是一种实用性强、应用范围广的耕整地机械,具有切土效果好、碎土能力强、耕后地表平坦等

特点,在各种土壤条件下一次性可达到待播状态,可基本满足农业精细耕作的要求。近年来,我国进行了种植

业结构调整,特别是北方地区,耕整用宽幅高速型旋耕机成为发展方向,大中型拖拉机具有强劲的动力输出、

较大的牵引力和悬挂提升能力,为配套旱地耕作型联合作业提供了先决条件。而旋耕作为驱动型耕作机械,易

于更换和附加工作部件,形成灭茬、深松、碎土、做畦、起垄、开沟、精量半精量播种、深施化肥、铺膜、镇

压和喷药等多项作业的结构紧凑的联合作业机组,大幅度提高了生产效率,降低了作业成本。本次设计的侧边

传动式旋耕机结构简单、生产率高、功率消耗少、经济效率高。

关键词:旋耕机;旋耕刀片;变速箱;传动系统

Design of Side Transmission TypeRototiller

Abstract: Rotary cultivator is a kind of soil preparation machine with strong practicability and

wide application. It cuts soil with good effect, breaks soil with powerful capacity and makes the

soil surface flat after tillage, and so on. It can make soil in all kinds of conditions once

achieved the state to be broadcast, which can basically meet the requirements of agricultural

farming. In recent years, the planting structure of our country has been adjusted, especially in

northern areas, thus tillage with a wide high-speed-type rotary tiller has developed. Medium-

sized tractor provides a prerequisite for supporting dry land farming-based combination process

with its strong power output, greater traction and enhanced ability of suspension. However, the

rotary cultivator machine, as a driven model rotary machine, is easy to change, subjoins working

parts and forms multiple-assignment and compact-structure joint operating units that clean

stubble, loose the soil deeply, break soil, do beds, ridge, ditch, sow precise and quantity

seeds, fertilize deeply, pave membrane, press soil and spray, which greatly improves the

production efficiency and reduces the assignments cost. This designed side transmission type

rotary cultivator in the paper has simple structure, high productivity, low power consumption and

high economic efficiency.

Key words:Rotary Cultivator;Rotary Blade;Gear-Box;Transmission System

目 录

摘要…………………………………………………………………………………1

关键词………………………………………………………………………………1

1 前言……………………………………………………………………………2

2 总体方案的选择及确定………………………………………………………3

2.1 工作方式的选择……………………………………………………………3

2.2 动力的选择…………………………………………………………………3

3 工作参数的计算及选择………………………………………………………3

3.1 刀片运动轨迹及其分析……………………………………………………3

3.2 机组前进速度与刀片回转速度的配合……………………………………5

3.3 耕作深度……………………………………………………………………5

3.4 切土节距……………………………………………………………………5

3.5 耕幅的确定…………………………………………………………………6

3.6 机具的配置…………………………………………………………………6

3.7 功率耗用……………………………………………………………………6

4 结构设计……………………………………………………………………7

4.1 传动方案拟订………………………………………………………………7

4.2 传动装置设计………………………………………………………………8

4.2.1 总传动比的计算及分配………………………………………………8

4.2.2 计算传动装置的运动和动力参数……………………………………8

4.2.3 圆锥齿轮计算及校核…………………………………………………9

4.2.4 滚子链传动的设计计算………………………………………………12

4.3 主要工作部件的设计及校核 ……………………………………………14

4.3.1 旋耕机刀片的设计……………………………………………………14

4.3.2 刀片的配置与排列……………………………………………………17

4.3.3 旋耕机刀轴设计………………………………………………………18

4.3.4 旋耕机刀轴的强度校核………………………………………………19

4.3.5 罩壳和平土拖板的设计………………………………………………22

5 机组的调整………………………………………………………………………23

6 结论………………………………………………………………………………24

参考文献 …………………………………………………………………………24

致谢…………………………………………………………………………………25

附录…………………………………………………………………………………25

|

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

声明:根据《互联网传播权保护条例》本站,小林机械资料商城,所列资料均属原创者所有,仅供学习交流之用,请勿转载并做其他非法用途。

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1