|

|

|

|

设计名称 |

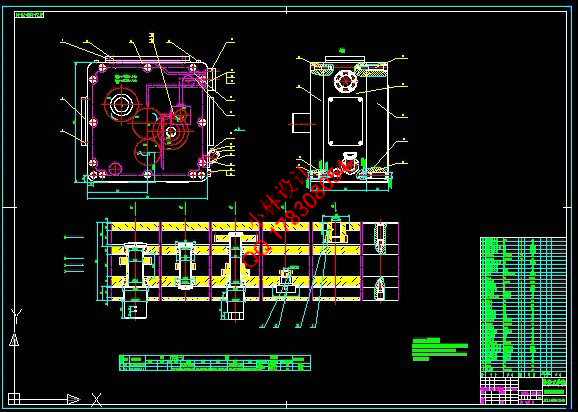

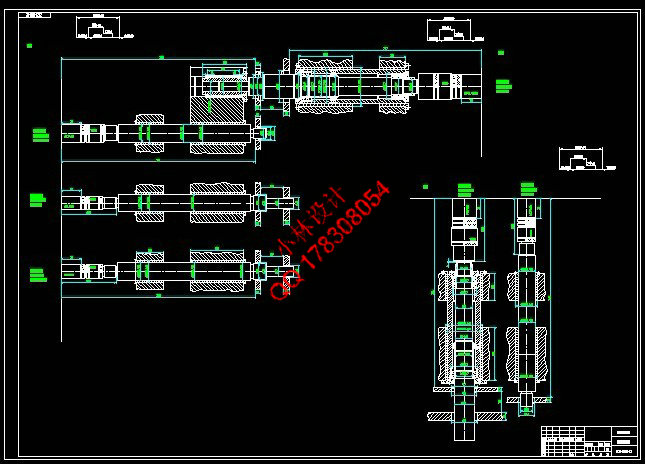

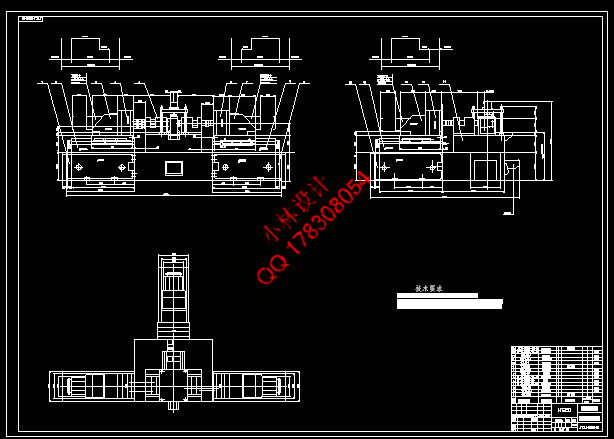

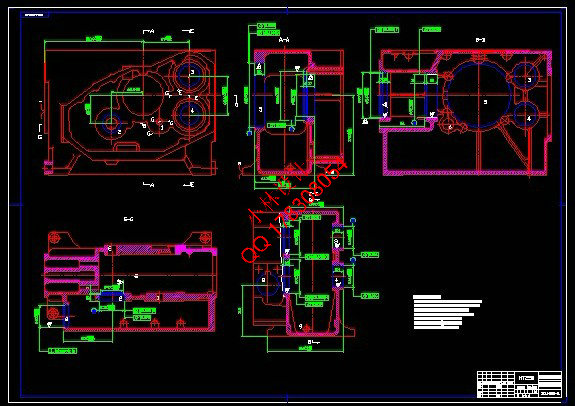

R180柴油机机体三面精镗组合机床总体及右主轴箱设计 |

|

|

设计编号 |

W314 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

14000字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

2014.2.12 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

文档包括:

CAD版本图纸,共16张 机机体三面精镗组合机床。该机床设计主要分为总体设计和部件设计两部分。在全面了解被加工零件的结构特 点、加工部位和技术要求等基础上。主要完成了组合机床的总体设计。具体内容是在确定总体方案的基础上, 绘制出三图(被加工零件工序图,机床联系尺寸图,加工示意图)和生产率计算卡。本课题的重点是对右主轴 箱的部件设计,首先,在完成组合机床总体设计的基础上,主要完成拟订了主轴箱的传动路线;然后,根据绘 制出的主轴箱原始依据图,确定了具体传动方案,应用最优化方法布置齿轮,确定传动参数,设计了轴的结构 ;最后,进行齿轮、轴承等相关零件的强度校核计算。在满足加工精度的条件下,本方案采用液压滑台来实现 进给运动,尽量使用了通用部件,降低制造成本。采用单工位三面同时加工能保证孔的位置精度,提高生产效 率,降低工人劳动强度,较好地满足了设计要求。 关键词:组合机床;精镗;主轴箱 The Overall and Right Headstock Design of Modular Machine Tool Used for Boring Holes of R180

diesel engine body machining efficiency and to satisfy the processing requirements, the combine machine-tool was designed for drilling and boring the body of the R180 diesel engine cylinder with three facing set. The focal point of this topic is the total design and the design of the right headstock. Basing on studying comprehensively the components in structure characteristic, processing spot and specification and so on, the overall design of the combine machine-tool was completed. Its concrete content is to finish three drawings (process components working procedure chart, engine bed relation dimensional drawing, processing schematic drawing) and the productivity computation card on the foundation of the overall plan. The key of this modular is the right headstock part design. Firstly ,On the basis of completing the total design of machine tool system, the driving route of the headstocks were drawn up. Then according to headstock primitive basis chart and the methods of optimization, the concrete transmission plan was determined, the cogwheels are disposed, the driving parameter were determined. At last, the structure of principal axis were designed and the strength of parts are checked such as the cogwheels and the axletree. Under the condition of satisfying the processing precision, the liquid operated sliding table is used for realizing the movement. The general part was used as far as possibly to reduce the production cost. What’s more, the single location three-side processing plan was used in the modular machine tool , which can guarantee the position precision of holes , enhance the production efficiency and reduce the worker labor intensity. It can satisfy the design requirement.

Key words: Modular machine tool; Boring holes; Headstock |

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1