|

设计描述:

文档包括:

设计word版本说明书一份,共21页,约8000字

CAD版本图纸,共21张

摘要

此设计是经济型中档精度数控车床横向进给系统 。面对我国目前机床数量少、工业生产规模小的特点,突出的任务是用较少的资金迅速改变机械工业落后的面貌。而数控车床(及其系统)已经成为现代机器制造业中不可缺少的组成部分。所以,实现这一任务的有效的、基本的途径就是普及应用经济型数控机床。

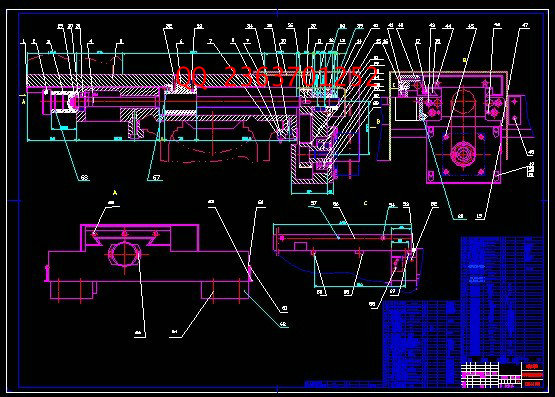

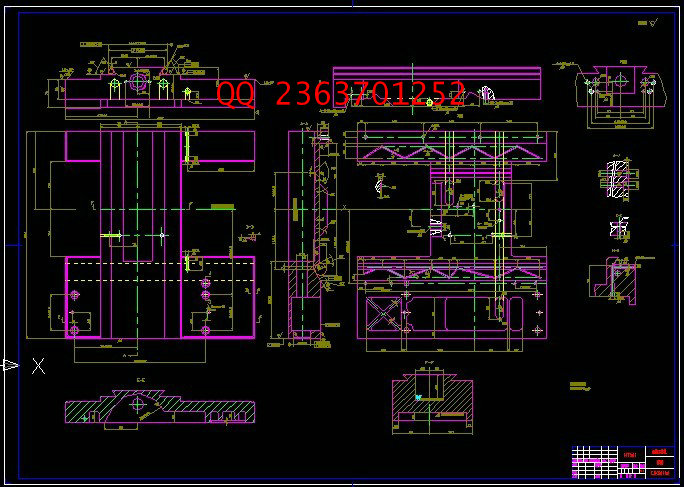

进给系统是由伺服电机经滚珠丝杠拖动工作台来完成的所以设计涉及伺服电机的选择,滚珠丝杠设计等。目前绝大部分的机床的横向进给均是采用滚珠丝杠来传递运动的,传动的精确性主要取决于丝杠支承形式,丝杠与伺服电机的联接方式。在设计中充分考虑到这两个问题,并且,设计精度须达原始数据。

关键词:滚珠丝杠 伺服电机 横向进给

Abstract

This design is the feeding operation of numerical control lathe with economic type of intermediate precision

In view to the quantity of machine tools in our country is not enough and the scale of industrial production is little at present, the outstanding task is to change our mechanical industrial appearance with less fund in short order.

And the numerical control lathe and its system have become an important part in modern manufacturing industry.

So, to realize this task, the effective and the basic channel is to use this economic type of numerical control lathe widely.

Feeding system goes normally with the ball screw which is droved by servo-motor dragging the workbench up and down.

So, this design includes the option of servo motor, the design of ball screw and so on.Now, the landscape orientation feeding of most machine tools is offered by ball screw. The accuracy of the transmission depends on mainly the form of the screw supports and the way of how screw and servo-motor to be joined. Besides the precision of the design needs Bases the primal data.

Consider these two questions in the design sufficient.

Keyword: holler-type thread Servo motor landscape orientation

目 录

0引言…………………………………………………………………………… 1

1 国内外发展概况及现状介绍………………………………………………… 2

2 总体方案论证 ………………………………………………………………… 4

2.1选择传动系统…………………………………………………………… 4

2.2选择传动装置…………………………………………………………… 5

3具体设计说明……………………………………………………………………6

3.1横向进给滚珠丝杠副的设计选择…………………………………………… 6

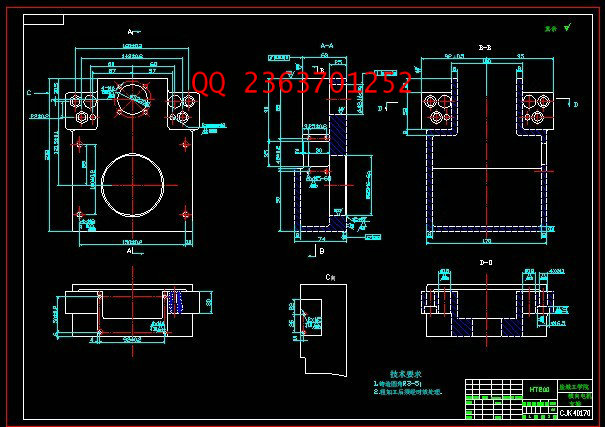

3.1.1确定滚珠丝杠的支承方式………………………………………………… 6

3.1.2滚珠丝杠副额定载荷…………………………………………… 7

3.1.3 滚珠丝杠副主要参数的确定…………………………………………… 8

3.1.4滚珠丝杠与伺服电动机的联接……………………………………… 12

3.2伺服电机型号选择…………………………………………………………… 15

3.2.1进给电机功率的确定……………………………………………………… 15

3.2.2伺服电机型号……………………………………………………………… 15

3.2.3同步带轮的选择……………………………………………………………15

4 结论……………………………………………………………………………… 17

5 参考文献………………………………………………………………………… 18

6 设计工作小节………………………………………………………………… 19

7附件清单………………………………………………………………………… 20

一、设计(论文)内容

本数控车床为经济型中档精度机床,横向进给运动要求用伺服电机通过柔性联结

带动滚珠丝杠螺母副实现,设计精度须达原始数据,丝杠要有安全防护罩。

二、设计(论文)依据

1、床身上最大回转直径φ400 mm;

2、快移速度 X轴4/min;

3、定位精度 X轴 0.035mm;

4、重复定位精度 X轴 0.0075mm,刀架0.010mm。

|