|

设计描述:

文档包括:

Word版说明书一份,共113页,约50000字

外文翻译一份

CAD版本图纸,共12张:

摘 要

本设计是霍州白辛二矿(白龙矿和辛置矿)3.00Mt/a矿区型选煤厂的初步设计。选煤厂工作制度为每年生产

330天,每天16小时,两班生产,一班检修。

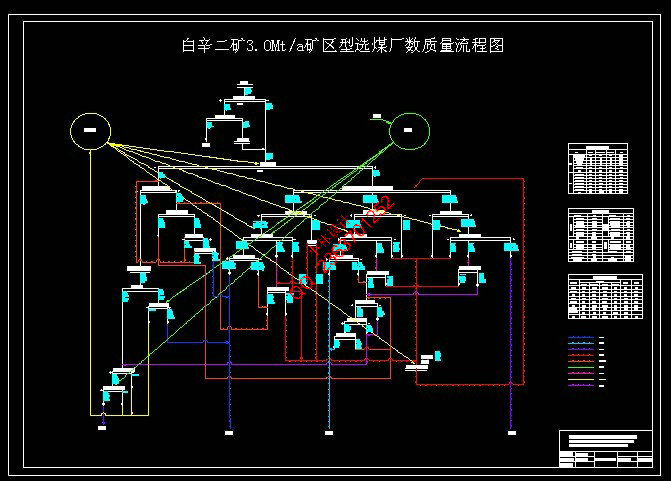

本设计先对煤质资料进行分析、校正、计算,确定原煤是否分组、分级入选,分析原煤的可选性。在此基础

上,通过几个可能的选煤工艺流程,对其进行产品预测和技术、经济比较,选出最佳方案:不分级无压入料

三产品重介质旋流器分选流程,煤泥采用浓缩浮选。

方案确定后,进行介质、数质量流程计算。依据计算结果,进行设备选型。设备选型时,优先采用技术先进

、性能可靠、效率高、能耗低、成熟可靠的设备。在工艺布置时,做到生产流程通畅,设备布置紧凑,并便

于安装、操作和检修。在总平面布置上,对辅助生产设施进行了规划,兼顾了环保的要求。

除工艺流程外,本设计还对选煤厂的建筑结构、供电和电气、机修车间、铁路运输、劳动定员、生产成本及

建厂初步投资概算做了系统的设计。

产品指标如下:

精煤:产率,49.38% 灰分,8.94% 水分 11.36%

中煤:产率,17.60% 灰分,31.55% 水分 9.35%

矸石:产率,25.31% 灰分,78.55% 水分 15.00%

关键词: 选煤厂;设计;全重介;浓缩浮选

ABSTRACT

This design is about Longxin No.2 mining,Huozhou, coal preparation plant with a capacity of

3.0Mt/a .The time of real production is 330 days one year, sixteen hours one day ;both teams

produce, one team repairs in a day .

We analysis、emend and account the data of coal data at first. Then discuss the raw coal

whether is grouped and graded and analysis the beneficiability of coal. On these occasions we

do product forecast on several process flow. Finally vote the preferred plan during these

process flows by comparing these economy and technology. The result of the process flow is no

sizing dense medium separation of wide range and floatation.

After scheme determined, we did the the count of process and manufacturing facilities

selection. The manufacturing facilities selection’s governing principle is that using the

advanced techniques dependable performance efficient and less energy consumption equipment. So

we can make the workshop laid out compacted and it will be convenient to install、operate and

overhaul. During the square arrangement, we make a comprehensive programme to the subsidiary

manufacture facilities.It fulfils the environmental protection requirement.

Besides the technological process, the project also include projects systematically about the

supplying of the electricity, the machine repairing, the railway transportation, the number of

worker, the budgetary estimate in economy, the budgetary estimate of the primary invest of

building of the plan and room.

The products are as follow:

Cleaned coal:Wt,49.38% Ad,8.94% Mt,11.36%

Steam coal: Wt,17.60% Ad,31.55% Mt,9.35%

Refuse: Wt,25.31% Ad,78.55% Mt,15.00%

Keywords:coal preparation plant ; design; dense medium separation of wide range; direct

floatation

目 录

1 总论……………………………………………………………………………………………1

1.1选煤厂类型、厂型及厂址 ………………………………………………………………1

1.2 工作制度…………………………………………………………………………………1

1.3入洗煤种及产品用途 ……………………………………………………………………1

1.4选煤工艺………………………………………………………………………………… 1

1.5 供水供电…………………………………………………………………………………1

1.5.1水源…………………………………………………………………………………… 1

1.5.2电源………………………………………………………………………………………2 1.6主要经济指标

……………………………………………………………………………2

2 选煤工艺……………………………………………………………………………………4

2.1 煤质资料分析及可选性研究……………………………………………………………4

2.1.1煤质资料的审查………………………………………………………………………4

2.1.2煤质资料的校正………………………………………………………………………4

2.1.3煤质资料的分析………………………………………………………………………5

2.1.4不排矸两矿煤质资料综合…………………………………………………………19

2.1.5动筛排矸两矿煤质资料综合……………………………………………………21

2.1.6是否分级入选讨论……………………………………………………………………26

2.2选煤工艺方案……………………………………………………………………………28

2.2.1初步选定的方案分析…………………………………………………………………28

2.2.2初步选定的方案预测…………………………………………………………………29

2.2.3方案技术、经济比较…………………………………………………………………54

2.3选定流程介绍与辅助工艺的确定………………………………………………………54

2.3.1辅助工艺确定…………………………………………………………………………54

2.3.2设计工艺流程整体描述………………………………………………………………67

2.4工艺流程计算……………………………………………………………………………68

2.4.1数质量流程计算………………………………………………………………………68

2.4.2介质流程计算…………………………………………………………………………69

2.5设备选型与计算…………………………………………………………………………84

2.5.1设备选型的原则与规范………………………………………………………………84

2.5.2主要设备的选型计算…………………………………………………………………85

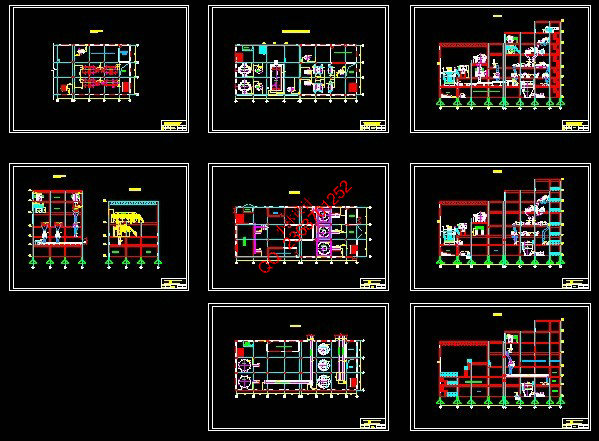

2.6选煤工艺布置……………………………………………………………………………90

2.6.1工艺布置原则…………………………………………………………………………90

2.6.2原煤受煤、配煤…………………………………………………………………………90

2.6.3主厂房…………………………………………………………………………………90

2.6.4产品仓…………………………………………………………………………………91

2.6.5尾煤系统………………………………………………………………………………91

2.7生产技术检查……………………………………………………………………………91

2.7.1检查内容及项目………………………………………………………………………91

2.7.2技术检查取样设置……………………………………………………………………93

3 建筑物和构筑物……………………………………………………………………………94

3.1 建筑设计…………………………………………………………………………………94

3.2 结构设计•………………………………………………………………………………94

4 给水排水……………………………………………………………………………………95

4.1 给水水源…………………………………………………………………………………95

4.2用水量和水压……………………………………………………………………………95

4.2.1用水标准及用水量……………………………………………………………………95

4.2.2水压……………………………………………………………………………………95

4.2.3消防……………………………………………………………………………………95

4.3给水系统…………………………………………………………………………………95

4.4排水………………………………………………………………………………………95

5 生产辅助设施………………………………………………………………………………96

5.1机修车间…………………………………………………………………………………96

5.1.1任务……………………………………………………………………………………96

5.1.2工作制度………………………………………………………………………………96

5.1.3人员编制………………………………………………………………………………96

5.1.4主要设备………………………………………………………………………………96

5.2介质准备车间……………………………………………………………………………97

5.3压风机房…………………………………………………………………………………97

6 电气部分……………………………………………………………………………………97

6.1供配电……………………………………………………………………………………97

6.1.1电源及供电方式………………………………………………………………………97

6.1.2供配电系统……………………………………………………………………………97

6.1.3照明……………………………………………………………………………………98

6.1.4避雷……………………………………………………………………………………98

6.2集中控制…………………………………………………………………………………98

6.2.1控制系统………………………………………………………………………………98

6.2.2控制原则………………………………………………………………………………99

6.3自动化……………………………………………………………………………………99

6.4通讯与广播………………………………………………………………………………100

7 铁路运输……………………………………………………………………………………100

7.1技术条件…………………………………………………………………………………100

7.2股道设置…………………………………………………………………………………100

8 采暖通风与药剂库…………………………………………………………………………100

8.1采暖………………………………………………………………………………………100

8.1.1概述……………………………………………………………………………………100

8.1.2采暖温度………………………………………………………………………………100

8.1.3采暖方式………………………………………………………………………………101

8.2除尘通风…………………………………………………………………………………101

8.3药剂库、油脂库…………………………………………………………………………101

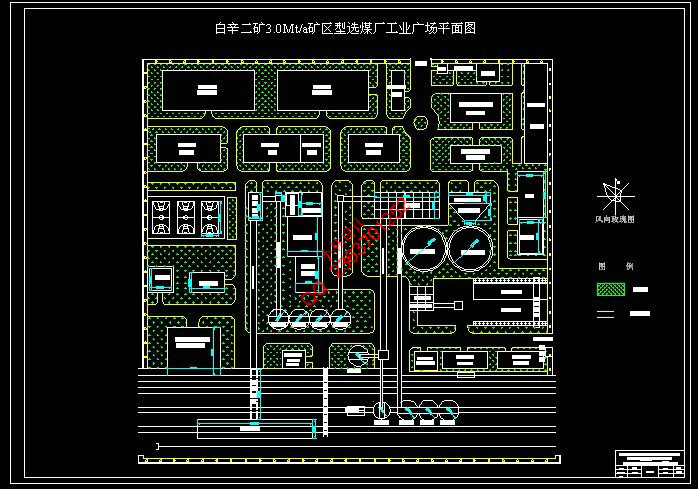

9 工业广场总平面……………………………………………………………………………102

9.1原始资料…………………………………………………………………………………102

9.2总平面布置………………………………………………………………………………102

9.2.1布置原则………………………………………………………………………………102

9.2.2生产设施布置…………………………………………………………………………102

9.2.3辅助设施布置…………………………………………………………………………102

9.2.4行政、生活福利设施布置……………………………………………………………103

9.2.5运输和绿化……………………………………………………………………………103

10 技术经济…………………………………………………………………………………103

10.1劳动定员………………………………………………………………………………103

10.2生产成本………………………………………………………………………………105

10.2.1产品销售收入………………………………………………………………………105

10.2.2分离前成本…………………………………………………………………………107

10.2.3分离后成本…………………………………………………………………………108

10.2.4财务分析…………………………………………………………………………109

11 环境保护…………………………………………………………………………………109

11.1环境保护设计依据及采用的环境保护标准…………………………………………109

11.1.1环境保护设计依据…………………………………………………………………109

11.1.2采用的环境保护标准………………………………………………………………109

11.2选煤厂污染防治措施…………………………………………………………………110

11.3厂区绿化………………………………………………………………………………110

12 劳动安全…………………………………………………………………………………110

12.1预防自然灾害措施……………………………………………………………………110

12.2防火防爆措施…………………………………………………………………………111 12.3防机械伤害和

人身安全措施…………………………………………………………111 12.4防触电伤害措施……………………

…………………………………………………111

|