|

|

|

|

设计名称 |

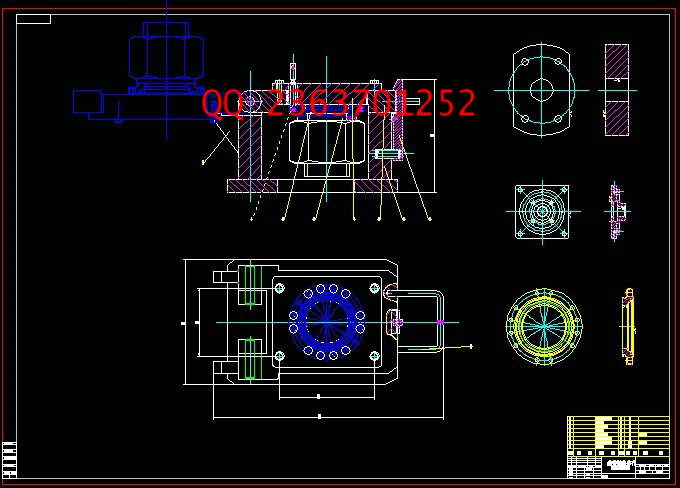

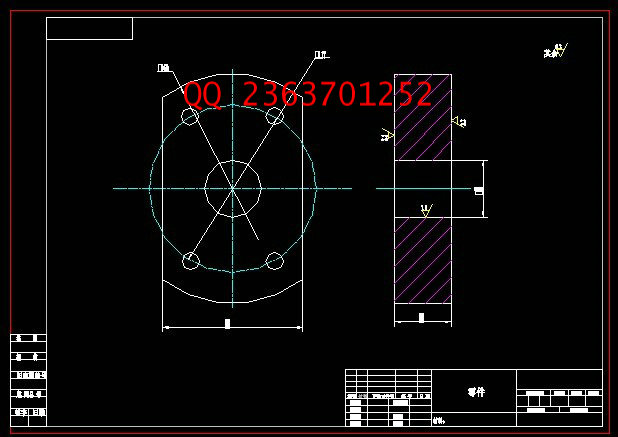

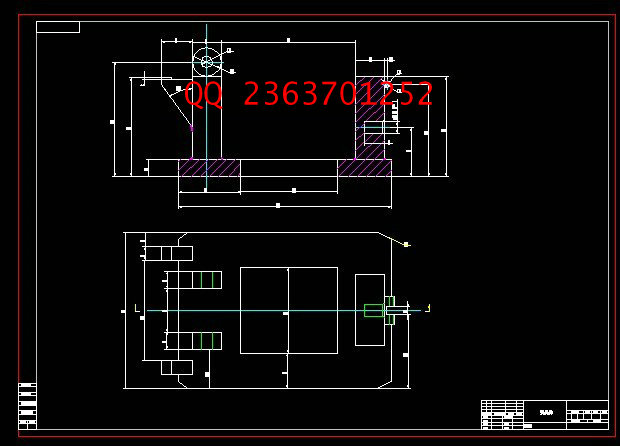

盘类轴向多孔成组钻模设计 |

|

|

设计编号 |

p119 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

10000字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

9.26 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

设计描述:

文档包括:

设计word版本说明书一份,共31页,约10000字

CAD版本图纸,共11张

2 前言????????????????????????????????????????????????????????????????????3 3 盘类轴向多孔成组钻模的设计???????????????????????????????????????6

3.1 盘类轴向多孔零件结克特点????????????????????????????????????9

3.3.1 定位元件的选择?????????????????????????????????????????11 3.5 夹紧装置的组成??????????????????????????????????????????????????13 3.6 钻套、衬套、钻模板及夹具体设计??????????????????????????????19 3.7 夹紧力的计算及夹紧元件的强度校核????????????????????????????28 3.8 夹紧机构的选择及设计??????????????????????????????????????????29 设计总结????????????????????????????????????????????????????????????????30 参考文献????????????????????????????????????????????????????????????????32 |

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1