|

|

|

|

设计名称 |

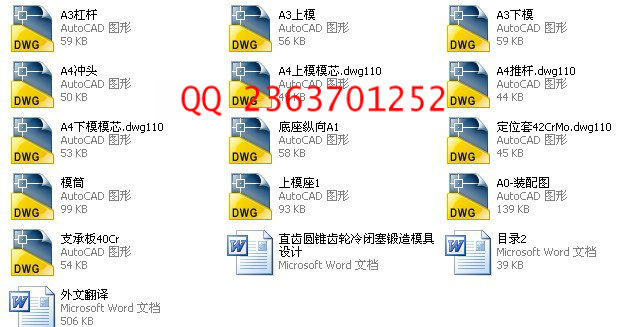

直齿圆锥齿轮冷闭塞锻造模具设计 |

|

|

设计编号 |

n016 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

24000字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

9.27 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

设计描述:

文档包括:

设计word版本说明书一份,共58页,约24000字

CAD版本图纸,共13张

目 录

摘要 Ⅰ

Abstract Ⅱ

第1章 绪论 1

1.1 国外的发展现状 1

1.2 国内的发展现状 2

第2章 冷闭塞锻造概述 4

2.1 闭式挤压 4

2.2 冷闭塞锻造成形的优点 4

2.3 挤压件分类 6

第3章 直齿圆锥齿轮三维实体造型及参数分析 7

3.1 三维实体造型软件介绍 7

3.2 直齿圆锥齿轮几何尺寸计算 7

3.3 直齿圆锥齿轮三维造型及计算其体积和质量 8

3.3.1 直齿圆锥齿轮三维造型过程 8

3.3.2 计算齿轮的体积和质量 9

第4章 直齿圆锥齿轮冷闭塞锻造工艺方案确定 10

4.1 冷锻件设计 10

4.2 毛坯尺寸的确定 11

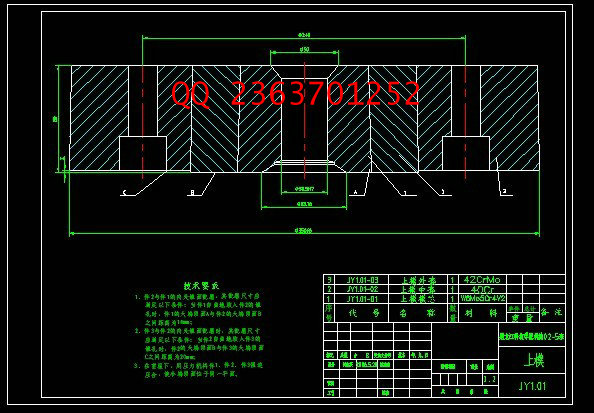

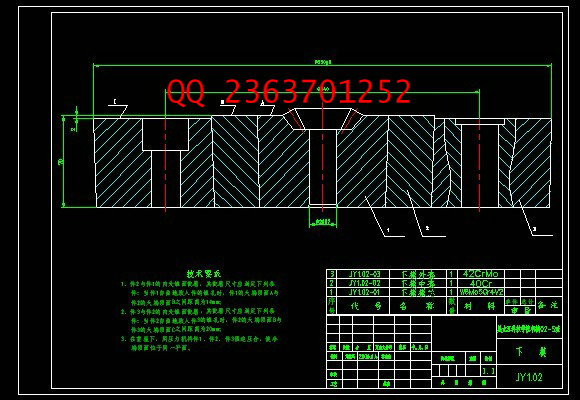

第5章 模具设计 12

5.1 挤压力的计算 12

5.2 冷闭塞锻造成形的特点 12

5.3 模具工作零件设计 13

5.3.1 模具设计前需要考虑的有关问题 13

5.3.2 凸模的设计 15

5.3.3 凹模的设计 17

5.3.4 杠杆的设计 21

5.3.5 导向、顶出件设计 26

5.4 模具总体结构设计 28

第6章 技术经济性分析 30

第7章 专题论文 31

结论 37

致谢 38

参考文献 39

附录1翻译(汉) 40

附录2翻译(英) 47

摘 要

冷闭塞锻造是国际上九十年代初出现的塑性加工最新技术,是现代计算机技术、材料科学、精密加工、测量技术和计算力学与传统塑性成形技术相结合的产物。作为最先进的精密成形技术之一,冷闭塞锻造工艺以其精密、优质、高效、低消耗、低成本、大批量等生产特点,成为世界塑性加工技术发展的重要方向。长期以来,我国汽车生产,尤其在精密成形技术方面处于落后位置。随着我国汽车生产,尤其是轿车生产的大规模化与全球性竞争的日趋激烈,积极开发冷闭塞锻造成套技术并使之尽快产业化意义重大。本人设计的是用闭塞锻造的方法直接加工成形直齿圆锥齿轮,即通过挤压封闭腔中的坯料来加工成形直齿圆锥齿轮,采用精锻(挤压)方法成形的齿轮有沿齿廓合理分布而连续的金属流线和致密组织,其齿轮的强度、齿面的耐磨能力、热处理变形量和啮合噪声等都优于切削加工的齿轮。与切削加工相比,精锻齿轮的强度可提高20%、抗弯疲劳寿命提高20%、热处理变形量比切削齿轮减少30%、生产效率提高了2倍以上、生产成本降低20%以上。生产批量在300~500件以上时,经济上更合理的。

关键字:直齿圆锥齿轮、闭塞锻造、挤压、凹模、凸模

Abstract

Cold unenlightened forging is the plastic processing newest technology which on the international at the beginning of 90's appears, is product which modern computer technology, the materials science, the precise processing, the survey technology and computation mechanics and the traditional plasticity forming technology unifies. One of as most advanced precise formed technologies, the cold unenlightened forging craft by its precise, high quality, is highly effective, production characteristic and so on the low consumption, low cost, mass becomes the important direction of the world plasticity processing technological development. Since long ago, our country automobile production is in the backward position especially in the precise formed technology aspect. Along with our country automobile production, the passenger vehicle produces large-scale and the global competition in particular is day by day intense, positively develops the cold unenlightened forging complete set technology and causes it as soon as possible industrial production watershed. My design with the unenlightened forging method direct processing forming straight tooth bevel gear, namely processes the formed straight tooth bevel gear through the precise drop forging, uses the finish forge method forming the gear to have along the tooth profile reasonable distribution but the continual metal streamline and the compact texture, its gear intensity, the tooth face wear-resisting ability, heat treatment Distortion Quantity and mesh the noise and so on all as a result of the machining gear. Compares with the machining, the finish forge gear intensity may enhance 20%, the anti- curved fatigue life enhances 20%, the heat treatment Distortion Quantity ratio cuts the gear to reduce 30%, the production cost reduces above 20%. Production batch when 300 ~ 500, in economy more reasonable.

Key words: Straight tooth bevel gear, Unenlightened forging, Extrusion, Concave mold, Raised mold.

|

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

声明:根据《互联网传播权保护条例》本站,小林机械资料商城,所列资料均属原创者所有,仅供学习交流之用,请勿转载并做其他非法用途。

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持! 皖ICP备2021006205号-1