|

设计描述:

文档包括:

Word版说明书一份,24页,约10000字

外文翻译一份

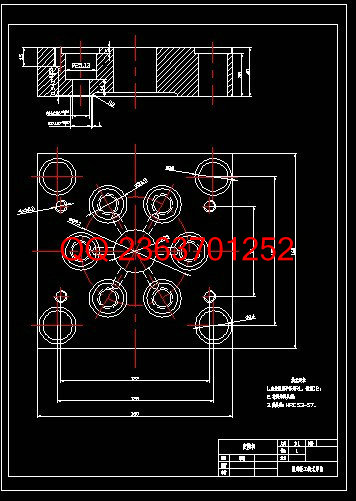

CAD版本图纸,共10张

题 目

铰链村套的成型与制造

论文(设计)的主要任务与具体要求

铰链村套产品目前市场的需求量非常大,价格低廉,市场竞争力大。从模具的角度考虑,要想降低成本,需设计手动动脱模式的模具。该产品的精度要求一般,结构简单。,硬件设计主要任务:

设计出模具总装图

工作原理说明

零件图

毕业设计(论文)说明书

注:1、毕业设计(论文)说明书字数8000左右;

2、设计图纸量根据设计内容而定,一般要求合一张A0图纸。

主要参考文献

[1].李德群 唐志玉.中国模具设计大典.江西:江西科学技术出版社,2003.1.

[2].塑料模设计手册编写组.塑料模设计手册.北京:机械工业出版社.1982.12.

[3]屈华昌.塑料成型工艺与模具设计.北京:机械工业出版社.2003.3.

[4]徐佩弘.塑料制品与模具设计.北京;中国轻工业出版社.2001.7.

中文摘要

模具生产的工艺水平及科技含量的高低,已成为衡量一个国家科技与产品制造水平的重要标志,它在很大程度上决定着产品的质量、效益、新产品的开发能力,决定着一个国家制造业的国际竞争力。

根据国内和国际模具市场的发展状况,有关专家预测,未来我国的模具经过行业结构调整后,将呈现十大发展趋势:一是模具日趋大型化;二是模具的精度将越来越高;三是多功能复合模具将进一步发展;四是热流道模具在塑料模具中的比重将逐渐提高;五是气辅模具及适应高压注射成型等工艺的模具将有较大发展;六是模具标准化和模具标准件的应用将日渐广泛;七是快速经济模具的前景十分广阔;八是压铸模的比例将不断提高,同时对压铸模的寿命和复杂程度也将提出越来越高的要求;九是塑料模具的比例将不断增大;十是模具技术含量将不断提高,中高档模具比例将不断增大,这也是产品结构调整所导致的模具市场未来走势的变化。

模具制造技术现代化是模具工业发展的基础。随着塑料制品在我们身边应用的越来越广,许多金属件慢慢被一些改性性塑料所代替。塑料工业得到了迅猛的发展,它的发展带动了塑料注射模的发展,使其成为当今很热门的行业。

关键词:金属件,塑料模具,注射模

ABSTRACT

Die in accordance with domestic and international market development, the experts predicted that China's future after the mold industry structure adjustment, the top 10 will show a trend of development: First, the increasingly large die and the other is the precision molds will become more and more high-third is Multi-functional complex mold will be further developed; Four die in a hot runner in the plastic mold will gradually increase the proportion of Fifth mold and gas-assisted injection molding, and other high-voltage adaptation of the mold will have greater development of standardization and 6 Die Die is the standard The pieces will be increasingly widespread application; seven rapid economic mold is very broad prospects for; eight die-casting mould is the ratio will continue to increase, while the die-casting mould of the magnitude and complexity of life will also be raised higher and higher requirements for the plastic mold of the 9 Will continue to increase ratio of 11 is the mold will continue to improve the technological content, in the proportion of high-grade mold will continue to increase, this product is the result of the restructuring mold the future trend of changes in the market.

Die die manufacturing technology modernization is the basis for industrial development. With the plastic products around us of the increasingly wide, many pieces of metal by some modification of the slowly replaced by plastic. Plastics Industry has been the rapid development, its development has driven the development of plastic injection mould, making it very popular in today's industry.

Key words: pieces of metal, plastic molds, injection -

目录

第一章前言……………………………………………………………………………4

第二章注塑机简介

2.1注塑机基本结构…………………………………………………………………5

2.2注塑机工作原理………………………………………………………………… 6

2.3成型周期(过程) ……………………………………………………………… 6

2.4注塑机液压系统简介……………………………………………………………6

2.5注塑机控制系统简介……………………………………………………………6

2.6注塑机加热系统简介……………………………………………………………6

2.7主要参数:压力/速度/时间/位置………………………………………………7

2.8辅助设备:………………………………………………………………………7

第三章课程设计

3.1课题设计…………………………………………………………………………8

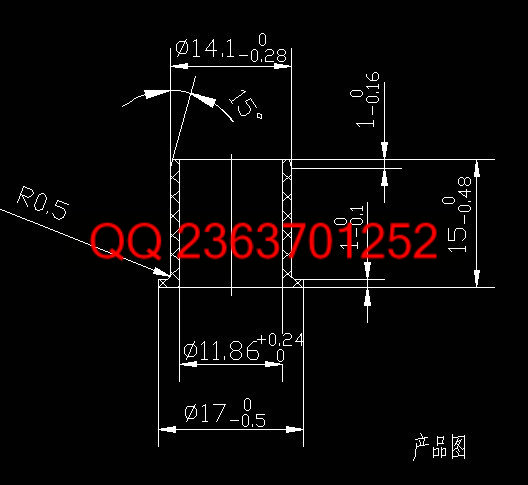

3.2塑件分析…………………………………………………………………………8

3.2.1塑件尺寸图分析……………………………………………………………8

3.2.2塑件的成型方法……………………………………………………………8

3.2.3塑件成型的工艺参数………………………………………………………9

3.2.4根据塑件的的计算重量或体积,选择注射机的型号规格,确定型腔数……………………………………………………………………………….

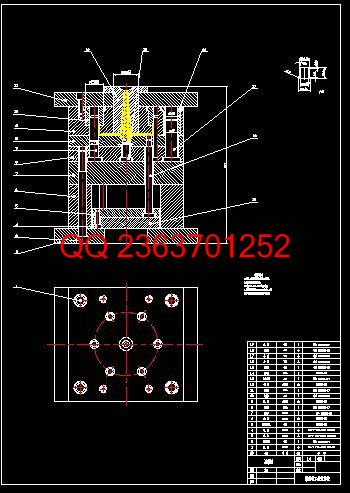

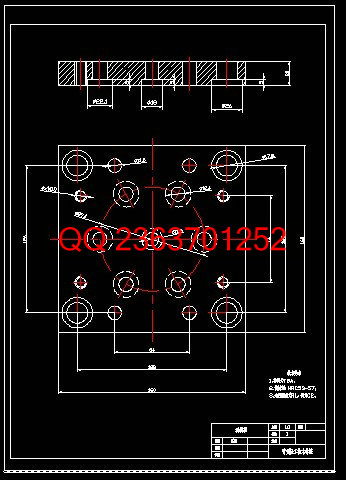

3.3模具结构………………………………………………………………………10

3.3.1模具的分型面………………………………………………………………10

3.3.2型腔布置……………………………………………………………………10

3.3.3浇注系统……………………………………………………………………10

3.3.4浇口的样式及尺寸…………………………………………………………11

3.4模具装配图……………………………………………………………………16

3.4.1装配图…………………………………………………………………16

3.4.2工作原理………………………………………………………………16

第四章设计小结……………………………………………………………………21

参考文献……………………………………………………………………………21

致谢…………………………………………………………………………………22

|