|

设计简介 |

设计描述:

文档包括:

Word说明书1份,共28页,约18000字

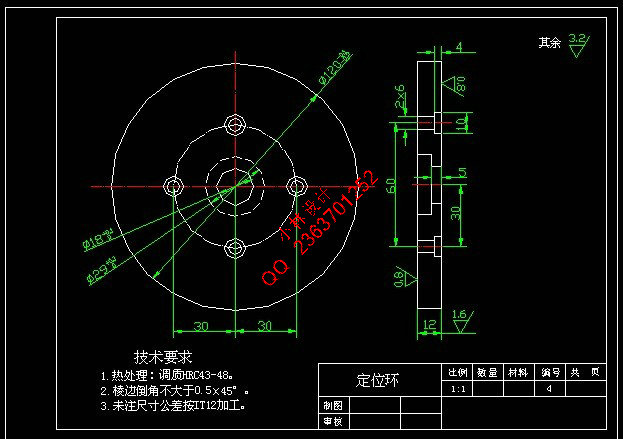

CAD版本图纸,共9张

皮带轮注射模及三维造型、装配

机械设计制造及自动化专业机械091 指导教师

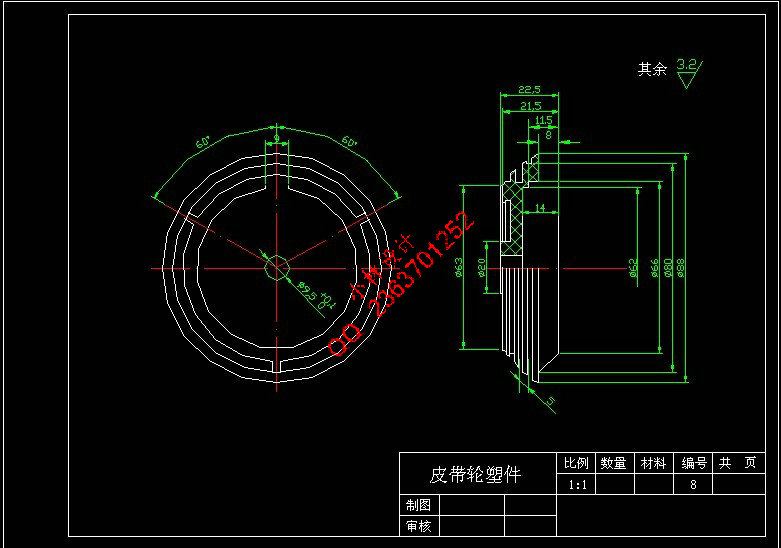

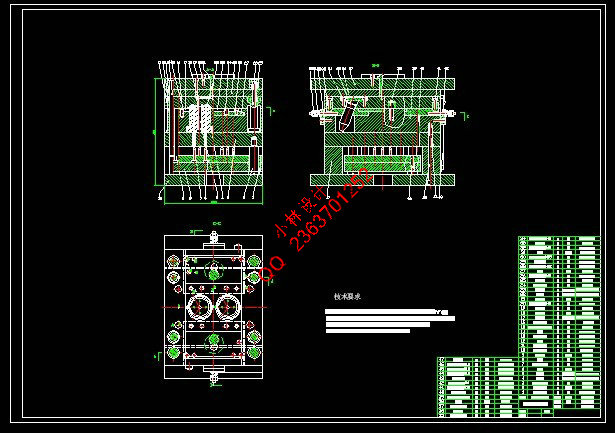

摘 要:基于塑料皮带轮的几何形状,材料性能、技术要求,完成塑料皮带轮模具的设计工作,该模具是一套塑料注射模具。在设计过程中,我选择斜导柱侧分型机构,而且把型腔设置在跟滑块固定的侧型芯上。其分型方式选择多个分型面同时分形,来完成型腔与塑件的分型。这样不仅使得该模具的结构得到了一定的简化,而且降低了这个模具的加工成本。为了提高模具在实际生产中的生产效率,采用了一模两腔的形式。在注射成型过程中,为了避免合模时滑块可能产生滑移,导致无法保证制品精度以及减少斜导柱在生产过程中的受力情况以及受力后的变形,我设置了楔紧块装置。为了保证斜导柱伸出端能够准确可靠地插入滑块端的斜孔中,要求滑块在完成抽芯以后仍然停留在刚刚脱离斜导柱的位置,不能发生任何的偏移,否则合模时斜导柱不能准确地进入滑块斜孔,因此设置了限位板对滑块进行定位。另外,合模完成后,为了避免两个滑块的位置发生左右偏移,导致型腔结构尺寸受到影响,必须在滑块合模终端位置设置定位机构,以保障两个滑块的位置不会发生不必要的偏移。此外还完成了该模具一些主要零件的加工工艺规程的编制工作。

关键词:皮带轮;模具;一模两腔;抽芯;注射模;

A pulley injection mold and molding process design

Mechanical Design, Manufacturing and Automation class 091 Qiuxiabing Instructor: Jiangjiefeng

Abstract:Based on to the plastic belt pulley's geometrical shape, the specification and the material performance's analysis, has completed the plastic belt pulley's mold project work, and this mold is a set of plastic injection mold .In the project engineering, has used a slanting guide pillar side minute organization, moreover the die space establishes, in fixes with the slide on the together side core .Its minute way has used at the same time many minute profiles fractal, then completed the die space with to model a minute. This not only enabled the mold structure to obtain the simplification, moreover also reduced this mold's processing cost .In order to raise mold's in actual production efficiency, has used mold two cavity forms. In the goods in process injection molding process, for avoids when the matched molds the slide has the slipping, is unable to guarantee that the product precision as well as reduces the slanting guide pillar after the work process stress situation and the stress distortion, must establish wedges tightly the block equipment. In order to guarantee that the slanting guide pillar extends the terminal to enter the slide end reliably accurately the slanting hole, the request slide after completing pulled out the core pauses just was being separated from the slanting guide pillar the position, could not have any displacement, when matched molds the slanting guide pillar could not insert the slide slanting hole accurately, therefore established the spacing tablet couplet slide to carry on the localization. Moreover, after the matched molds completes, about to prevent two slide positions to occur displaces, causes the die space structure size to receive the destruction, must in the slide matched molds finally position establishment detent mechanism. In addition has also completed this mold some major parts processing technological process establishment work.

Key words:Belt pulley;Mold;The side pulls out the core;A mold two cavity;injection mould

目 录

1 引言 - 1 -

1.1塑料及塑料工业发展 - 1 -

1.2塑料工业在国民经济中的作用 - 1 -

1.3模具工业在国民经济中的重要性 - 1 -

1.4本模具的总体说明 - 2 -

2 塑料材料及塑件几何形状 - 2 -

2.1塑料材料的简介 - 2 -

2.2分析塑件的结构、尺寸精度及表面质量 - 3 -

3 注射机的选用 - 4 -

3.1 计算制品的体积和质量 - 4 -

3.2 初步选定注射机 - 4 -

4 确定型腔数及位置布局方案 - 6 -

4.1型腔数的确定 - 6 -

4.2型腔布局方案 - 6 -

5 确定模具结构方案 - 7 -

5.1确定分型面 - 7 -

5.2确定模架组合形式 - 7 -

5.3.1主流道设计 - 9 -

5.3.2主流道衬套的设计 - 9 -

5.3.3分流道设计 - 10 -

5.3.4.浇口的设计 - 11 -

5.3.5.冷料穴的设计 - 12 -

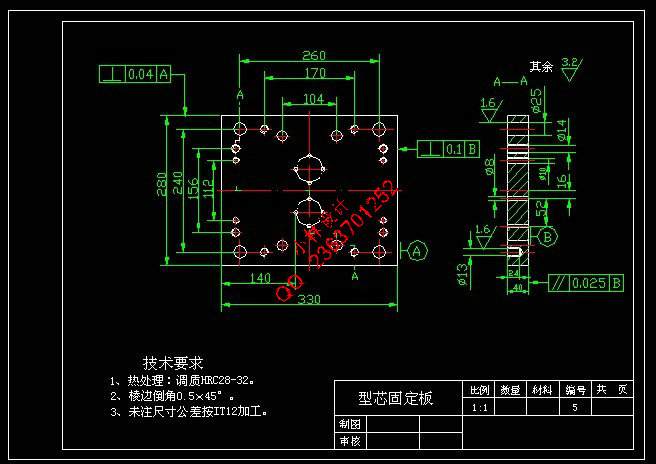

5.4成形零部件的设计 - 12 -

5.4.1.确定成形零部件工作尺寸 - 12 -

5.4.2.侧向分型与抽芯机构设计 - 13 -

5.4.3.排气系统的设计 - 16 -

5.5注射模结构零部件设计 - 17 -

5.5.1.合模导向机构 - 17 -

5.5.2.设计推出脱模机构 - 17 -

5.6推出零件的设计 - 18 -

5.7复位机构的设计 - 18 -

5.8脱模力的计算 - 18 -

5.9 推出零件尺寸的确定 - 19 -

6 模具各部分的校核 - 20 -

6.1注射量的校核 - 20 -

6.2注射压力校核 - 20 -

6.3锁模力校核 - 20 -

6.4模具高度与注射机闭合高度的关系校核 - 20 -

6.5开模行程的校核 - 21 -

7 结论和模具结构图 - 21 -

参考文献 - 21 -

致谢 - 23 -

|