|

|

|

|

设计名称 |

塑料水杯的模具设计与加工 |

|

|

设计编号 |

V164 | |

|

设计软件 |

AutoCAD, Word | |

|

包含内容 |

见右侧图片 | |

|

说明字数 |

19000字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

2013.9.26 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

设计描述:

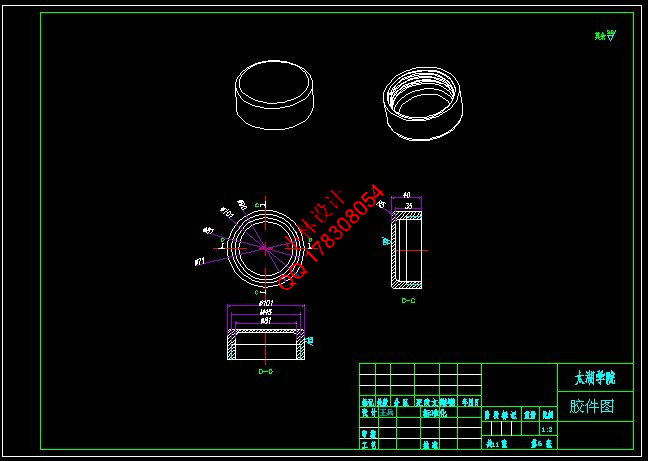

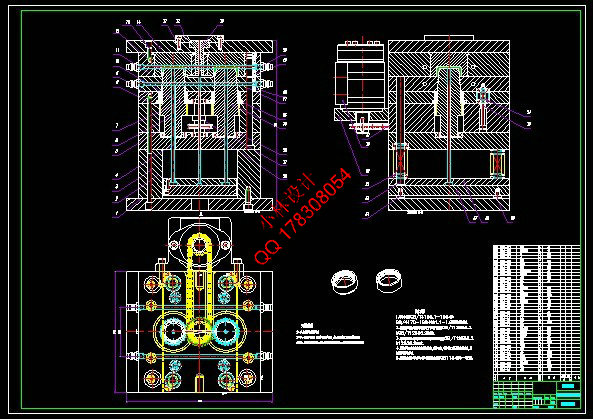

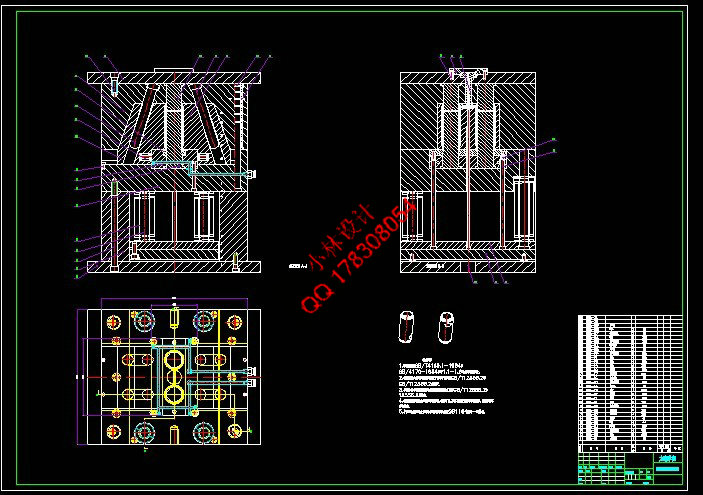

文档包括: CAD版本图纸,共21张

具成型部分和总装结构的设计,通过对模具结构方案、模具工作过程以及加工注意事项的详细分析与论述。近 年来CAD/CAM技术已发展成为一项比较成熟的共性技术,模具CAD/CAM技术的硬件与软件价格已降低到中小企业 普遍可以接受的程度,塑料制件及模具的3D设计与成型过程的3D分析正在塑料模具工业中发挥越来越重要的作

用。我感觉UG开模相对于CAD开模有相对简单,2D图采用CAD制图,开模采用UG制图。 程中,重点突出了造型设计,成型零件设计,模架设计三个重要工作,在设计中用到了分流道侧浇口浇注系统 。在其中造型分模中遇到一定的困难,但是通过努力最终得以解决。这次设计是对塑件及模具CAD/CAM、UG的一

次大胆尝试,相信对实际生产会有一定的指导意义。 咖啡、方便人们生活,大的杯径可让杯子多盛放东西,需要时还可以用做饭盒,两个不同的杯盖还可以交换使

用。本次设计以有内螺纹的杯盖为主,杯体为辅。

Abstract the quality of plastic parts, the design of gating system, the ejector design system, molding part and final assembly structure, the die structure scheme,Detailed analysis and discusses the working process of the mould and processing notices, try hard to let readers know the design process of injection mold.In recent years, CAD/CAM technology has developed into a relatively mature technologies, the technology of mould CAD/CAM hardware and software, the price has been reduced to small and medium-sized enterprises generally acceptable degree, 3D analysis of 3D design and molding process of plastic parts and mold is playing a more and more important role in the plastic mold industry.But I feel UG mold mold is relatively simple compared to CAD, 2D map

using CAD drawing, mold using UG mapping. the analysis, the various parameters of the check, and the mapping of the drawings.In the design process, focused on the design, the design of molding parts, mold design are three important work, the shunt side gate system used in the design of. There are some difficulties in the other part, but through hard work finally settled.The design of plastic parts and mold CAD/CAM, UG is a

bold attempt, I believe there will be some guiding significance for practical production. and a cup bottom have a certain space, can be put in the tea, coffee, convenient for people living, large cup size can let the cup to hold things, when required, can be used as a lunch box, two different cup cover can also be used. This design mainly with the internal thread of the cup cover. Key words:Plastic cup; Plastic cup cover; Injection mold design; CAD/CAM

目 录 |

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持!