|

设计简介 |

设计描述:

文档包括:

Word版说明书一份,共53页,约25000字

外文文献翻译一份

CAD版本图纸,共12张:

摘 要

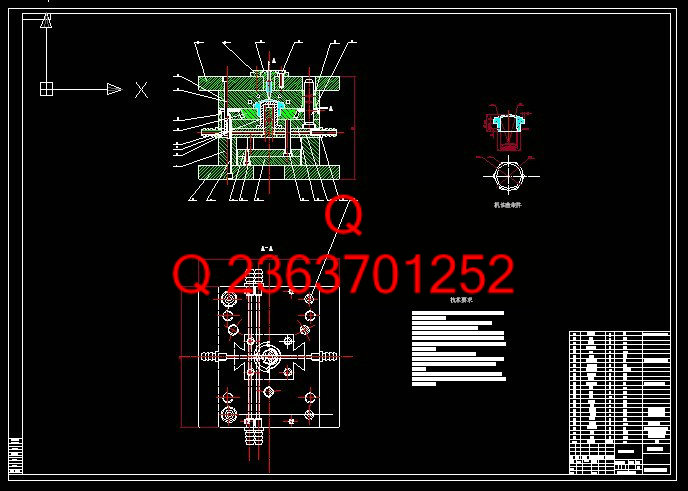

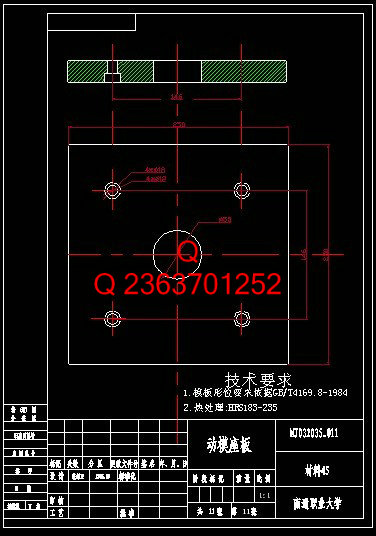

本篇设计说明书大体分为三大部分,第一部分是绪言,内容包括注塑模具的概述,塑料成型模具在加工工业中的地位,塑料模具的发展趋势以及塑料成型模具的分类。第二部分是注塑模具的总体设计, 内容包括塑料注塑模具的工作原理及应用, 设计准则以及材料的选择与产品见解. 注射机类型的选用, 注射机有关工艺参数的校核,浇注系统设计(浇口形式的选择以及尺寸计算,主流道尺寸的计算,冷料穴,排气槽),塑料注塑模具的设计计算, 包括模具结构设计[分行面的确定,凹模(型腔)结构形式,凸模的结构形式,凹模(型腔)和凸模工作部分的尺寸计算],导向机构的设计,推出机构的设计,抽芯机构的设计,冷却系统的设计等方面. 第三部分是介绍CAD/CAM在模具设计与制造上的应用, 包括Pro/ENGINEER实体设计,AutoCAD平面二维图纸的绘制,CAXA图幅,图框,标题栏的调用。

关键词: 塑料,注塑模具,注塑机,CAD/CAM

Abstract

This design instruction booklet divides into three major parts roughly, the first part is the introduction, the content including casts the mold the outline, the plastic takes shape the mold in processing industry status, the plastic mold development tendency as well as the plastic takes shape the mold classification. The second part is casts the mold the system design, The content casts the mold including the plastic the principle of work and the application, Design criterion as well as material choice and product opinion Injection machine type selection, Injection machine type selection, The injection machine related craft parameter examination, pours the system design (runner form choice as well as size computation, main flow channel size computation, Leng Liaoxue, exhausts trough), the plastic casts the mold the design calculation, Including the mold structural design [ the branch surface determination, the concave mold (cavity) the structural style, the raised mold structural style, the concave mold (cavity) and raised pattern making makes partial sizes computation ], the design, pulls out the core organization the design, cooling system aspect and so on design The third part introduces CAD/CAM In mold design and manufacture application, Including Pro/ENGINEER The entity design, the AutoCAD plane two-dimensional blueprint plan, the CAXA map sheet, attempts the frame, the title block transfer.

Key word: The plastic, the note molds, injection molding machine, CAD/CAM

目 录

第一章 绪言............................................1 1.1注塑模具的概述...... ..................... .................. ..1

1.2塑料成型模具在加工工业中的地位.. .............................2 1.3塑料成型模具的发展趋势............................... ...3 1.4塑料成型模具的分类..... ........................... ......4 第 二 章 注塑模具的设计.....................................6 2.1 零件材料的选择及材料性能.... .. ............... .... .......... .6

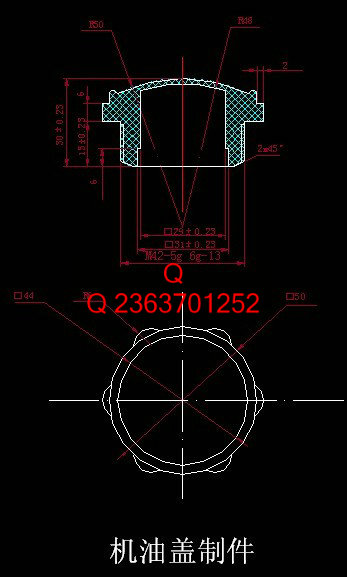

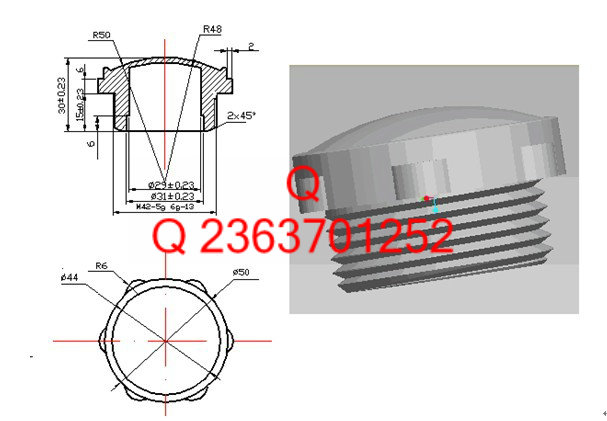

2.1.1机油盖注塑模具设计的简况. .. . .. ........... .......... .... ..6

2.2 塑料注射成型模具的设计....................................8 2.2.1注射机类型的选择... .... .. ....... ....... .. ...............8

2.2.2注射机有关工艺参数的校核. .......... .......... .............8

2.3 浇注系统的设计..... .................... .....................10

2.3.1浇口形式: 采用点浇口式.. ..... ...... . ........... ..........11

2.3.2主流道尺寸的计算. .... ........ ........ ...................13

2.3.3冷料穴....... ....... ....... ....... ........ .............14

2.3.4排气槽....... ...... ... ............... ....................14

2.4 成型零部件的设计.... ........... .... .... ....................15

2.4.1模具分型面及其类型. ........ ..... . ........................15

2.4.2成型零件的结构形式.... ........ .... ........ ..............15

2.4.3成型零件的强度计算....... ...... ....... ....................18

2.5 导向机构设计... ... ... ........... ..........................19

2.5.1导向机构的设计过程. ....... ............ ....................19

2.6 推出机构设计........... .. .. .................................21

2.6.1推出机构的概述..... ..... ........ ........ .................21

2.6.2 推杆结构设计...... ......... ..... ........................22

2.6.3 推板结构设计...... ........ ...... ... .. ..................23

2.7 抽芯机构设计... ........... ...... ............................23

2.7.1抽芯机构概述..... . ........................................23

2.7.2斜滑块抽芯机构设计. ........ ........ ........ ..............25

2.8冷却系统的设计.... .......... .......... ......................26

2.8.1影响冷却通道设计的因素.. ......... ....... ..................26

2.8.2冷却系统设计的基本原则... ....... ....... .......... .......26

2.8.3冷却系统的形式.. . ..... ..... .. ..... ...... .. ..... .....27

2.8.4冷却装置设计... ..... ...... . ..... . ..... . ..... ........27

2.9 本章小结 ........ ..... . ..... ...... .. . ..... ..... ..... .28

第三章 CAD/CAM部分 . .. ..... . ..... . ..... . . ..... ..... ..... ..29

3.1 CAD/CAM设计. . .... ..... .. ..... .. ..... ..... ........ .. .29

3.1.1Pro/ENGINEER软件使用. ..... .... .. ..... . ..... . ..... .. 29

3.1.2 AutoCAD软件使用... ..... . ..... . ..... . ..... . ..... .....30

3.1.3 CAXA2006软件使用. ..... . ..... . ..... . ..... ...... . ...30

3.2 本章小结... ..... . ..... . ..... . .. ..... .... .... ... ... ..31

设计总结与展望...... ..... ...... .. ..... . . ..... ..... .. . ....32

参考文献 ... ..... . ..... .. .. ..... . ..... ..... ........... . 33

致谢........... .. . ..... ..... .. ..... ...... ...... .. ...........34

附件1:滑块加工工序卡、型芯加工工序卡、型腔板加工工序卡....... .....35附件2:现代快速经济制造模具技术(中英文)... .. ....... ...... .. ..38

|