|

|

|

|

设计名称 |

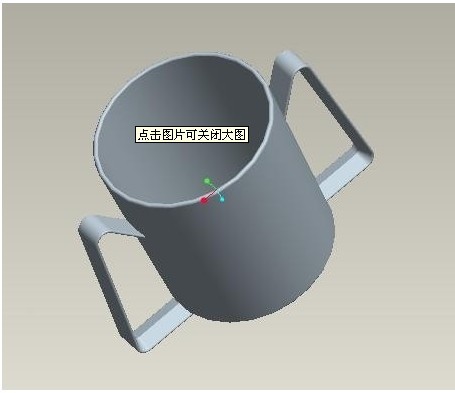

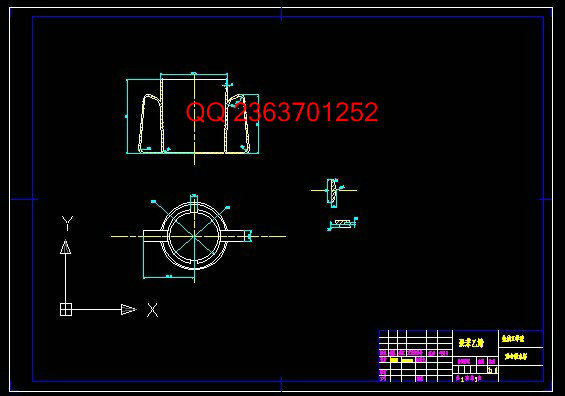

儿童吸水杯注塑模设计PROE三维 |

|

|

设计编号 |

u106 | |

|

设计软件 |

AutoCAD, Word | |

|

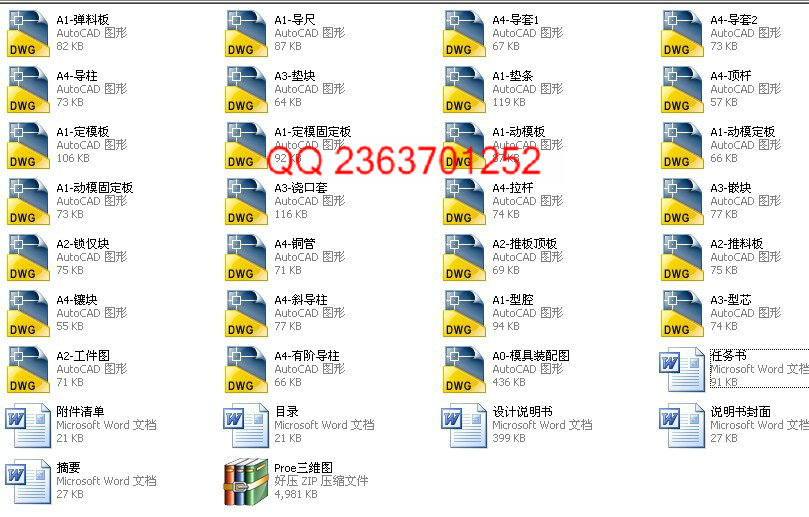

包含内容 |

见右侧图片 | |

|

说明字数 |

12000字 | |

|

图纸数量 |

见右侧图片 | |

|

推荐指数 |

较高 | |

|

价格: |

价格优惠中 | |

|

整理日期 |

9.26 | |

|

整理人 |

小林 | |

|

购买流程 |

<查看如何购买本站设计> |

|

设计简介 |

设计描述:

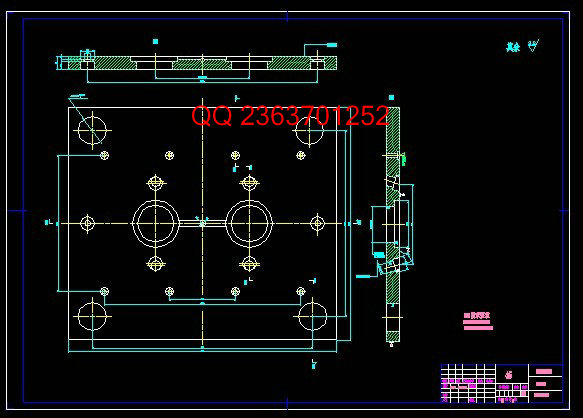

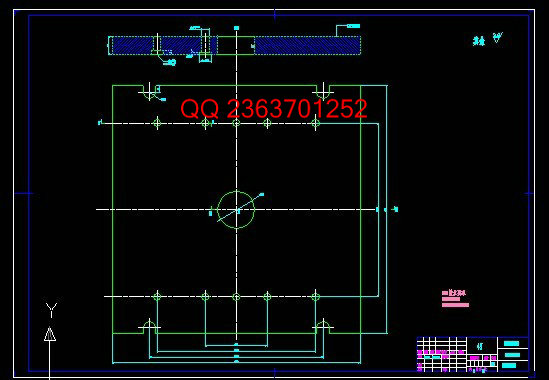

A0-模具装配图.dwg

本文就如何应用先进技术设计制造注塑模具,更新设计注塑模具的方法,解决好注塑模具设计的关键-------浇注系统、顶出系统、冷却系统侧面分型与抽芯机构的合理设计,以期与同行们一起讨论,共同努力推动注塑模具技术的发展。本文就童心吸水杯注塑模具设计展开,根据零件的结构特点、材料特性,构思总体方案并进行方案论证。依据总体方案对注塑模具总体结构进行合理设计,然后分六个分支系统进行设计,它们分别是浇注系统、冷却系统、注塑模具零件设计、注塑零件成型零件工作尺寸计算、侧向分型机构设计与抽芯机构设计、和其它设计。其中浇注系统、冷却系统设计的是否合理是模具设计成败的关键,针对浇注系统本设计从浇注系统的组成和作用、主浇道设计、分流道设计、浇口设计、浇注系统动平衡、冷料井与拉料杆合理搭配六个方面进行设计和论证。 Abstract On how this text use advanced technical design make and mould plastics the mould summary, Upgrade and design method to mould plastics mould , settle well and mould plastics key of mold design ------ -Pour the system, carry and offer the system, cooling system side dividing into type and smoking the rational design of the core organization, In the hope of and discuss with colleagues together , make joint efforts and promote and mould plastics mould development of technology. This text absorb water on childlike innocence cup mould plastics cup launch, according to structure characteristic, material characteristic of part, Overall scheme of the plot and carrying on schemes to prove. The mould ensemble architecture is designed rationally to moulding plastics according to the overall scheme, Then divide the system of six branches to design, They pour the system separately, Cooling system, mould plastics mould part design, mould plastics part shaping part working size calculate, side direction person who divide organization design and release design, and other designs, organization of core,. It is rational that the ones that pour the system, cooling system and design among them are a key to the mold design success or failure, Originally designed from pouring systematic com and function to the system of pouring, Water line design, shunt dishes of design, runner not to design, pour systematic dynamic equilibrium, cold material well with draw material pole collocate 6 designed and proved rationally mainly. Keyword mould plastics mould pour system carry and publish the systematic cooling system side assigning to type and smoke the core mechanism

目录

一、设计(论文)内容

二、设计(论文)依据

三、技术要求

四.毕业设计(论文)物化成果的具体内容及要求

|

|

部分图纸 截图 |

|

|

说明: |

如需了解本设计的具体详细信息请联系本站客服,说明看哪个设计(编号)哪个详细部分,我们将远程或截图给您观看. 机械毕业设计|论文 |

| [要求PR≥2,百度收录≥1000页;联系QQ:178308054] |

Powered by 小林机械资料商城 © 2013-2020 All Rights Reserved. 客服QQ:178308054

喜欢www.xiaolinbysj.com,请告诉你QQ上的5位好友,多谢您的支持!