|

设计简介 |

设计描述:

文档包括:

说明书一份,61页,22000字左右.

英文翻译一份.

CAD版本图纸,共7张:

摘 要

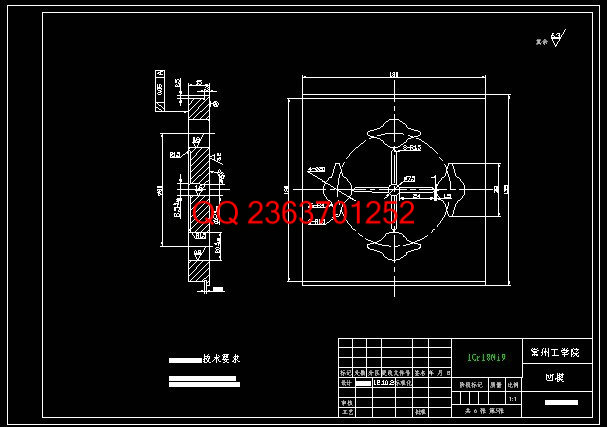

注射模具在模具行业有着很重要的地位,而注射模具的发展离不开塑料工业的发展,注射成型是热塑性塑料成型的主要方法之一。通过这种方法可以制作出复杂的塑料制品,而且一副模具一个成型周期可以同时成型多个制件,生产效率高,因而广为采用。此次设计的题目是“蝶形螺帽注射模设计”。首先,需要进行工艺分析:确定分型面,浇注系统等,选择注射机,计算成型零部件的尺寸,确定是否采用冷却系统。然后进行结构设计:确定模架以及导向机构、紧固件选取、脱模机构设计等等。最后对模具结构与注射机的匹配和重要尺寸进行校核。此次设计要保证满足工艺要求和结构要求。

关键词:注塑模 塑料 注塑机 脱模机构

ABSTRACT

Injection Mold has a very important position in die industry, and injection mold development is inseparable from the development of the plastics industry, Injection molding of the thermosplasticity plastic molding one of the principal ways. Through this method can produce complex plastic products, and a mold forming a molding cycle can form more products, high production efficiency and thus widely adopted. This design is entitled "butterfly nut injection mold design". At First, the need for process analysis: decide the type face, gating system, choose injection machine, the sizes’ calculation of the molding parts, to determine whether to adopt the cooling system. Then the structural design: identification module racks, as well as guidance, the selection of fasteners, the design of parting and so on. Finally, the injection mold structure and the matching machine size and importance check. This design process to ensure that the technology requirements and meet the requirements in terms of the structure.

Keywords: injection mold plastic injection molding machine the ejection mechanism

目 录

中文摘要........................................................................................................I

英文摘要........................................................................................................II

第一章 概述.............................................................................................................1

1.1国际、国内塑料模具成型发展概况与对比 ...............................1

1.1.1国际塑料模具成型发展概况 ......................................1

1.1.2国内塑料模具成型发展概况 ..................................... 1

1.1.3我国模具与国际模具相比存在的主要问题............................ 1

1.2塑料模具设计方法主要发展方向 ..................................... 2

1.3毕业设计课题资料查询.................................................. 4

1.3.1分析塑件结构及工艺技术要求 ........................................ 4

1.3.2了解注塑机的技术规格 ..............................................4

1.3.3了解塑件的工艺性能和加工性能,塑料熔体流动行为,塑料在模具内可能的结晶,取向及导致的内应力 ............................................... 6

1.3.4塑料的适用范围...................................................... 8

1.4毕业设计思想简述................................................. 8

第二章 塑料制件的工艺性分析及工艺结构设计.........................9

2.1成型塑料制件结构工艺性分析.............................................9

2.1.1尺寸精度分析....................................................... 9

2.1.2塑料制件结构设计...................................................9

2.1.3粗糙度分析.........................................................9

2.1.4斜度设计....................................................9

2.1.5壁厚设计....................................................9

2.1.6圆角设计....................................................11

2.2塑件三维CAD建模及CAE分析........................................11

2.2.1利用CAD建模,完成三维零件的设计...............................11

2.2.2 CAE分析及其不同方案结果比较:..................................12

2.3根据分析结论进行模具工艺设计........................................... 16

2.3.1型腔数量的决定..................................................... 16

2.3.2型腔布置........................................................... 18

2.3.3 确定分型面.........................................................19

2.3.4确定浇注系统和排气系统............................................. 21

第三章 选择注射机及注射机工艺参数校核................................. 28

3.1注塑机的技术规范.......................................................28

3.2注塑压力校核(可计算、可应用CAE分析结论)...............................28

3.3锁模力的校核...........................................................28

3.4模具厚度的校核..................................................29

3.5 开模行程的校核................................................. 29

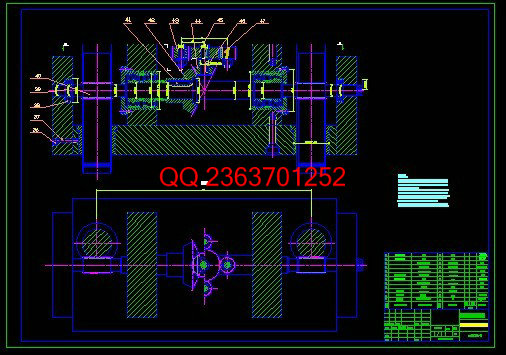

第四章 模具设计................................................... 30

4.1确定标准注塑模架................................................ 30

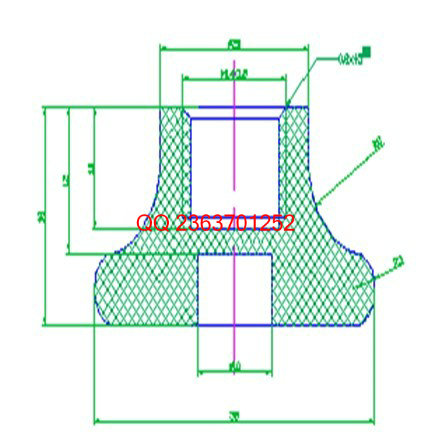

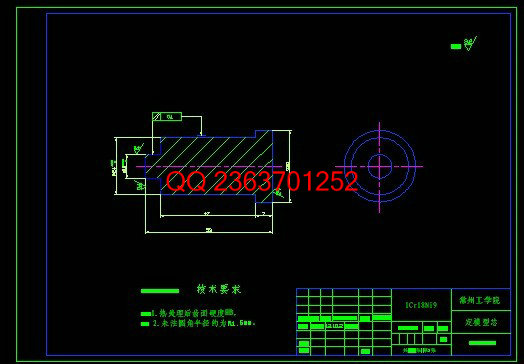

4.2模具成型零件设计...................................................31

4.2.1成型零件设计.................................................31

4.3型腔成型尺寸计算.................................................33

4.3.1成型零件设计....................................................... 33

4.4模具主要零件选择…...................................................... 38

4.5脱模机构的设计................................................. 44

4.5.1脱模机构方案的确定................................ ........... 44

4.5.2齿轮传动的设计...............................................46

4.6模具冷却系统设计................................................ 50

4.6.1模具热平衡计算.............................................. 50

第五章 绘制模具图................................................. 53

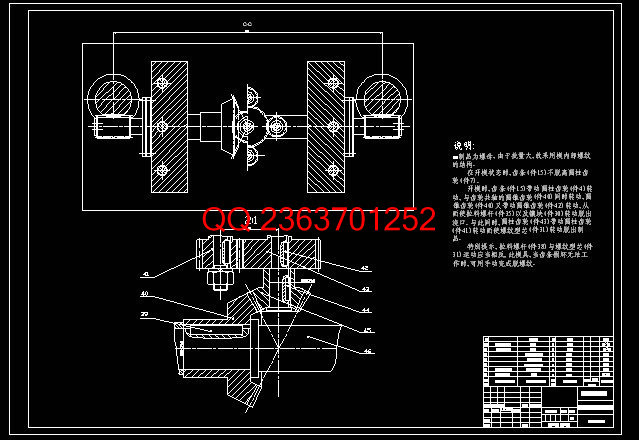

5.1绘制总装结构图.................................................. 53

5.2绘制重要零件图.................................................. 53

5.3校对、审图......................................................53

第六章 结论.................................................................................................... 55

致谢.........................................................................................................56

参考文献.........................................................................................................57

附录A:圆柱齿轮参数计算程序....................................................................58

附录B:圆锥齿轮参数计算程序....................................................................60

|